Contents

Facts about material handling: –

- It does not add to the value of the product but to the cost of the product.

- It accounts for 36% of the total production cost.

- Nearly 50 – 100 tons of material are handled or re-handled for every tone of the finished product.

- A large part of the labor cost is accounted for by the material handling department.

- About 66.66% of manufacturing cycle time is spent in handling the material.

- About 40 accidents out of 100 accidents take place due to material handling.

Classification of lifting material/appliances: –

Tips for good erection & rigging: –

Material handling safety

- First, find out the correct weight of the load to be lifted in RIGGING AND ERECTION.

- Slightly lift the load check for CG, imbalance, etc.

- While lifting ensures that the load is not obstructing any of the parts of the structure.

- While using spanners, riveting hammers at height tie with a rope to a fixed structure.

- Loose nuts & bolts must be kept in a box and not on the structures. The box to be properly anchored.

- Avoid sudden break or sudden release of the load. Impact load may result in breaking of the rope/chain.

- Persons with B.P or epilepsy shall not be allowed to work at heights.

- Barricade the area of loads lifting/ sparks falling.

- The safety belt is a must at heights more than 1.8 meters in RIGGING AND ERECTION.

CLICK HERE FOR > SAFE WORKING LOAD (SWL)

CLICK HERE FOR > RIGGING EQUIPMENT

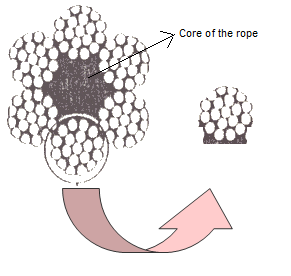

Construction of 6/19 wire rope: –

6=no. of strands

19 =no. of wire ropes in each strand

19(1/6/12) I.e 12wires over 6 wires over one wire.

Type of cores: –

- Fiber core: sisal, polypropylene or nylon

- Wire core : IWRC (Independent wire rope core), SSC (steel strand core) or Armor core

Construction of 6/19 wire rope in RIGGING AND ERECTION

- Ordinary: all wires in the strand are of the same diameter.

- scale: larger diameter wires outside and smaller inside. This arrangement gives more resistance to abrasion.

- Warrington: alternative large and small wires are formulated to give great flexibility, resistance to abrasion.

- Firlle: small wires filled between large outer and inner rows of large size wires.

CLICK HERE FOR MATERIAL HANDLING SAFETY

SWL of natural ropes: –

Reduction in diameter of the rope due to core failure, abrasion, etc.

Should not be more than

- 1.0 mm for the ropes up to—19mm dia

- 1.5mm for ropes of————22-28mm dia

- 2.0mm for ropes of ————32-38mm dia

WIRE ROPE SAFETY IN RIGGING AND ERECTION:

- Never over load.

- Minimize shock loading to the extent possible.

- Use higher capacity ropes when the exact load is not known. If there is a possibility of shock loading and if there is a hazard to personnel.

- Prevent the rope from sharp corners with padding.

- Avoid dragging the rope from under loads or over obstacles.

- Avoid dropping the rope from heights.

- If loop forms do not pull it out. Unfold it.

- The rope must be replaced if the visible broken wires are 5% or more of the total wires in a length of 10 rope diameter.

- The rope must be replaced if this wear exceeds 1/3 of the diameter of the wire.

- An approximate elongation of 150 mm per 30 M of rope in a six-stranded rope and approximately 230 to 255 mm in eight stranded rope can be expected when a new steel rope is put in use, which is known as constructional stretch. Ropes having an excessive stretch beyond this should be replaced.

CLICK HERE FOR HIRA AND JSA

Precautions in use of chains:-

- Chains or chain slings should never be shortened by tying knots in them.

- Do not use the chains if the links are locked, stretched or without free movement.

- Do not hammer a link to straitened it or force it into the position.

- Do not drop chains from heights.

- Use padding at sharp corners.

- Use slings such that the angle between slings is more than 90 dig.

Type of hitches in material handling:-

- Bridle hitch

- Basket Hitch

- Choker hitch

Bridle hitch

Basket Hitch

Double basket hitch:

Inclined legs SWL=SWL of single vertical hitch x H/L x4

Choker hitch

Double choker hitch, SWL=SWL of single vertical hitch x A/B X H/L x2 when the angle is less than 45 dig.

Note: If the angle is more than 45 dig. Take A/B=3/4

As for as possible the angle between the two slings to be ensured less than 90 dig , so that only limited excess weight is coming on each sling.

Minimum number of clips

up to 19 mm—– 3

19-32mm——— 4

32-38mm——— 5

38-44mm——– 6

above 44mm—- 6

CLICK HERE FOR MECHANICAL HANDLING SAFETY

The bridge of the bull-dog grip to come load side and U-bolt on the shorter end of the rope, don’t tight the grips too much tight or too loose. The clips shall be kept 6 dia of the rope apart.

CLICK HERE FOR CRANE INSPECTION POINTS

Proper Method of Lifting a Load (Manually):-

- Place your feet firmly on the ground about one foot apart.

- Keep your one leg slightly in front of the other and as close to the load as possible.

- Bend your knee and hip with the back straight (“Straight” does not mean “VERTICAL”)

- Keep the load close to the body

- Grip the load firmly from opposite ends by ensuring contact between the object and the palm.

- Lift the load in such a way that your chin remains straight in line with your back (this will help you to keep your spine straight and firm) and the vision is not disturbed/obstructed

- Position body so its weight is centered over the feet and lift by straightening the legs

- Put down the load again by bending hip and knee by keeping the back straight.

- One corner should be put first to remove fingers from another side.

Gas cylinders safety -10 commandments:-

- Don’t store them near wet soil or exposed to sun or heat source

- Do not use them as work supports or rollers (maybe the cylinder full or empty

- Do not lubricate the cylinder valve threads or other fittings

- Cylinders must be maintained in an upright position and secured against tipping, falling or rolling. Never drop cylinders or permit them to strike each other violently.

- Protect the surface of the cylinder from any cuts or abrasions.

- Valve protection caps must be fully threaded in place when cylinders are not connected to user system.

- Do not carry the cylinder on your shoulder.

- Never lift cylinders by the caps.

- Never open the acetylene more than 1/2 turn, sudden opening may lead to explosion

- never keep the cylinders in the battery charging room or never allow them to come in to contact with live wires.

Also, read this:-

Six steps for safe manual material handling

Trailer safety at construction site

Operating Crane Safety

You are reading at rlshumancare.com. Do not forget the name RLS HUMAN CARE. Please share with your friends and help RLS HUMAN CARE. Thank You!!

nice rigging mythology and correct lifting patterns

how to make SHE Plan

It is good information about rigging safety