Contents

What is the safe working load (SWL)?

Safe Working Load (SWL) is the limiting safety factor to lift and carry any load safely. It must be clearly marked on any lifting device (hoist, lifts, lifting machines, and lifting tackles).

Section 28(1)(c) of the Factories Act, prescribes as under:

“The maximum safe working load (SWL) shall be plainly marked on every hoist or lift, and no-load greater than such load shall be carried thereon”

Section 29(1)(b) of the same Act, prescribes as under:

“No lifting machine and no chain, rope or lifting tackle shall, except for the purpose of the test, be loaded beyond the safe working load which shall be plainly marked and duly entered in the prescribed register, and where this is not practicable, a table showing the safe working loads of every kind and size of lifting machine or chain, rope or lifting tackle in use shall be displayed in prominent positions on the premises”

CLICK HERE FOR 👉 EOT CRANE SAFETY

Rule 60 of the Gujarat Factories Rules 1963 Safe working load require that:

- The safe working load has to be specified by a competent person after testing and examination.

- Where the safe working load may be varied by the raising or lowering of the jib, a table indicating the SWL at the corresponding indication of the jib or corresponding radii of the load shall be attached with the jib-crane.

- A table showing the SWL (Safe Working Load) of every kind and size of chain, rope, or lifting tackle in use, and in case of multiple slings, the SWL at different angles of the legs, shall be posted in the storeroom.

Marking System of Safe Working Load

Lifting equipment should have a tally plate indicating the Safe Working Load. The tally plate also indicates the identification number which can be mentioned in the test certificate held by the user. It should also indicate the date of the last inspection.

CLICK HERE FOR 👉 SCAFFOLDING

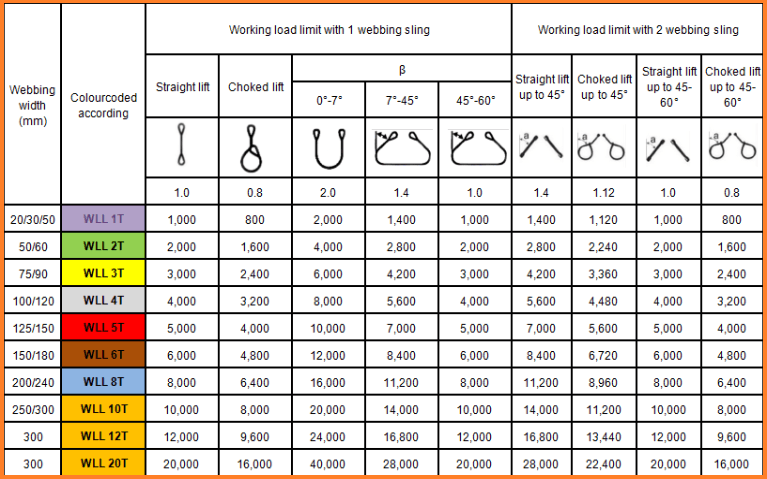

Safe Working Load of different types of the sling are given in the picture below:

Place of marking of Safe Working Load (SWL) of different equipment is shown in the table below:

| Type of Equipment | Place of Marking of SWL |

| Lifting eye bolt | Side of the eye. Size and type of thread also be marked. |

| Shackles | On one leg SWL and on another leg identification mark and symbol are marked. |

| Chain Sling | On terminal fitting (ring) or on a separate idle link. |

| Multiple legged slings | SWL at 90° angle is marked on the upper terminal ring. |

| Wire ropes | A metal sleeve or tag with marking is attached. |

| Chains | Marking for quality of material on every 20th link or 3 feet apart |

| Hooks | SWL on one side of the non-vital part and on the reverse side the identification mark. |

Where marking on the body part is not possible it should be shown by tagging.

Calculation of Safe Working Load (SWL):

For wire rope, FS is 6 for general purpose and 7 for heavy industry. A thumb rule formula is

SWL = (Wire rope dia)2 × 8 kgs

Example – For 12 mm dia wire rope

SWL = 12 × 12 × 8 = 1152kgs

Forsling, SWL depends on the length of the sling leg (L) and the headroom between the hook and the load (H). Then for bridge hitch

CLICK HERE FOR 👉 TYPES OF SCAFFOLDING

For single hitch

SWL = SWL of single verticle hitch × H/L × 2

For double basket hitch

SWL = SWL of single vertical hitch × H/L × 4

For hoist, lift, cranes, etc., Safe working Load is recommended by the manufacturer.

Safe Working Load (SWL) of any mobile crane depends on the operator’s skill, condition of the ground, boom length, the radius of rotation while lifting the load, the inclination of the boom to the vertical and outrigger blocked or free.

Safe Working Load is generally tabulated in the load chart of the crane. Sometimes, it is de-rated(decreased) due to defect in welding, bend in angle, bracing, etc., and condition of clutch, brake, etc. Modern cranes give a digital display of SWL, angle indicator, boom limit switch, and alarm for exceeding load.

CLICK HERE FOR 👉 DOWNLOAD BIS 2762 (2009): Wire Rope Slings and Sling Legs

The factor of safety / Safety factor

The factor of the safety (Safety Factor) of fiber ropes varies from 6 to 12 mm depending on the conditions of use. fiber rope less than 12 mm dia should not be used for a sling or apart of a lifting appliance. Their factor of safety (FS) varies with diameter. The factor of Safety for the hook, wire rope sling, chain, fiber rope, and belt are given in the table below:

| No. | Lifting Item | Factor of Safety |

| 1. | Mild Steel Hook | 5 |

| 2. | High Tensile Steel Hook | 5 |

| 3. | Wire Rope Sling | 6 |

| 4. | Endless Wire Rope Sling | 8 |

| 5. | C Hook | 5 |

| 6. | Shank Hook (General Purpose) | 5 |

| 7. | C Hook with Eye (0-25 Ton) | 4 |

| 8. | Point Hook with Shank (63-160 Ton) | 5 |

| 9. | Hook (General Purpose 1-25 Ton) | 4 |

| 10 | Hook (General Purpose 25-100 Ton) | As per IS: 7847 |

| 11. | Chain Grade: 30 | 4 |

| 12. | Chain Grade: 40 | 4 |

| 13. | Chain Grade: 63 | 4 |

| 14. | Chain Grade: 80 | 4 |

| 15. | Chain Sling | 4 |

| 16. | Eye Hook for Chain Sling | 4 |

| 17. | Synthetic Fiber Rope | |

| Diameter | ||

| 12 mm. | 12 | |

| 14-17 mm. | 10 | |

| 18-23 mm. | 8 | |

| 24-29 mm. | 7 | |

| 40 and above | 6 | |

| Polyester Belt | 7 (For Belt) 4 (For Lifting Belt) |

Proof Test

Proof testing is the application of a load greater than the SWL (Safe Working Load) to detect defective workmanship, faulty weld or other inherent weaknesses. It is not a means to assess the SWL which should only be done by calculations and checked where necessary by suitable tests on samples.

CLICK HERE FOR 👉 SCAFFOLDING COUPLERS WORKING LOAD CAPACITY

CLICK HERE FOR 👉 JSA

The proof test is required as a part of ‘thorough examination’ u/r 60(1) of GFR and no lifting machine or tackle should be used for the first time without this proof test.

In general, the proof load applied to chains, rings, hooks, shackles, and similar gear is twice the SWL. It should be just under the yield stress for the material.

The standard proof load for mild steel or wrought iron short link chain is as under:

| Grade | Test load in Tons |

| 30 | 12 (d)2 |

| 40 | 16 (d)2 |

| 60 | 24 (d)2 |

| 80 | 32 (d)2 |

Where ‘d’ is the diameter of the material from which the chain is made.

All items used in lifting machinery should be subjected to proof test loads as under:

| Item | Proof Test Load |

| Chain, ring, hook, shackles, swivel, sling, individual components of the hoist, wire rope, chain, pulleys, hooks, eye bolts, pins, axles, bearings, turnbuckles & ringing screws. | 2 SWL |

| Single sheave pulley blocks | 4 SWL |

| Multiple sheave pulley blocks | |

| Up to 20 Ton | 2 SWL |

| Up to 40 Ton | SWL + 20 Ton |

| Over 40 Ton | 1.5 SWL |

| Electric Hoist Cranes (Mobile & EOT) | |

| Up to 20 Ton | 1.25 SWL |

| 20 to 50 Ton | SWL + 5Ton |

| Over 50 Ton | 1.10 SWL |

| Endless slings | 4 SWL of single part |

| Derricks | 1.25 SWL static & 1 SWL for all full movement |

After the above proof test, the parts are to be examined thoroughly by a competent person for signs of cracks, fatigue, deformation, permanent stretch, etc.

CLICK HERE FOR 👉 HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

Also, read this:

Safety in rigging and erection operations

NOW ITS YOUR TURN / अब आपकी बारी

PLEASE SHARE THIS ARTICLE WITH YOUR RELEVANT FRIENDS

शेयर करें

what should be the overall factor of safety of an EOT crane?

if i have to design a crane of 5 ton lifting capacity then for how much load i should design its bridge girder?

I don’t want to be left aside

Your Safety Literatures, and Safety Documents are excellent and very much user friendly, I like those very much. Please continue to send such valuable Safety / HSE study materials, and help Industry, Business and Society. Many thanks

Regards,

dwijottam.chattopadhyay@gmail.com

00971 – 544487137

Rigging and Lifting JSA, SOP and Standard.

PLEASE PROVIDE HIRA OR RISK ASSESSMENT

*Alumino thermit for the activity.

*De-stressing of long weldrail.

*Flashbutt welding ultrsonic flaw detection test

*installation of ballast less turnouts

*installation of ballast less tracks