Hazards, Material safety data sheet (MSDS) and its interpretation. the properties mentioned in MSDS are dangerous properties needing attention for safety Sch 9 of MSICH Rules, 1989, and Sch. 5 u/r 68j (2) of GFR 1963, statutorily require this information. The occupier of a factory has to keep this information ready to show to the workers on request.

Contents

Classification of Air borne Contaminants:

When chemicals are disseminated in air and contaminate it, they are called air-borne contaminants. They are classified according to their physical state as under:

(A) Gases and Vapors:

(1) Gases:- Normally formless fluid which occupy the space of enclosure and which can be changed to the liquid or solid state only by the combined effect of increased pressure and temperature gases diffuse. The particle size varies from 0.0005 to 0.01 micron.

Example are chlorine, ammonia, sulfur dioxide, Hydrogen sulfide (H2s), Hydrogen cyanide, carbon monoxide, etc. Main pollution are oxides of carbon, sulfur and nitrogen.

(2) Vapors:- The gaseous form of substance which are normally in the solid or liquid state and which can be changed to these states by either increasing the pressure or decreasing the temperature alone. Vapors diffuse. The particle size varies from 0.005 to 0.01 micron.

Examples are vapours of lead oxide, benzene, xylene, trichloroethylene, and other solvents.

Gases and vapors are also classified as under:-

- Organic solvent vapors eg.. alcohol acetone, CS2, CCI4, benzene, xylene.

- Pulmonary irritant gases eg. CL2, NO2, phosgene.

- Upper respiratory irritant gases NH3, SO2, formaldehyde, acetic acid.

- Chemical asphyxiant gases CO, CHN.

- Simple asphyxiant gases H2. CO2, methane, its homologues and acetylene.

- Other inorganic and organic gases H2S, arsine and pesticides vapors.

(B) Particulate Matters:-

These are solid tiny particles produced by blasting, crushing, drilling, grinding, mixing etc. and suspended in air. Examples are as under:

(1) Dust : Solid particles generated by handling, crushing, grinding, rapid impact, detonation and decrepitation of organic or inorganic materials such as rocks, metal, coal, wood, grain etc.Dusts do not tend to flocculate except under electrostatic forces. They do not diffuse in air but settle under the influence of gravity. The particle size varies from 0.1 to 1000 microns. Fly ash from chimneys varies from 3 to 80 microns.

(2) Fumes : Solid particles generated by condensation from the gaseous state, generally after volatilisation from molten metals etc. and often accompanied by a chemical reaction such as oxidation. Fumes flocculate and sometimes coalesce. The particle size varies from 0.001 to 100 microns. Examples: lead, zinc. or nitrous fumes.

(3) Mists : Suspended liquid droplets generated by condensation from the gaseous to the liquid state, such as by splashing, foaming and atomising. The particle size varies from 50 to 100 microns. Example : sulphuric acid mist.

(4) Smokes : Small gas-borne particles resulting from incomplete combustion and consisting predominantly of carbon gaseous material are grouped in this category. The particle size varies from 0.1 to 1 micron.

(5) Smog and Fog : The air contaminants may be present in the forms of smog and fog which are not usually encountered in an industrial environment. The particle size varies from 1 to 50 micron.

(6) Aerosols : It is a colloidal system in which the dispersion medium is a gas and the dispersed phase is solid or liquid. The term aerosol is applicable till the solids or liquids remain suspended in the gaseous media. The particle size varies from 0.01 to 100 micron. Dust, smoke or mist are examples.

Aerosols affect weather, damage materials and impair health. Atmospheric aerosol like hydrocarbons, lead, arsenic, sulfuric acid etc. may injury human health because of their toxic nature.

Routes of Entry & Toxic Effects:

Routes of Entry (Avenues) to Human System:

Following are the four main routes of entry of toxic material into human body :

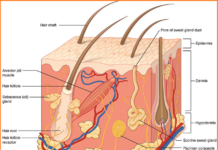

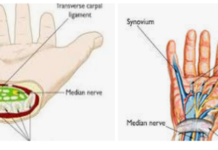

(1) Absorption through skin (Dermal tract) : Skin absorption attains its greatest importance in connection with the organic solvents. The significant quantities of these compounds may enter the body through the skin either as a result of direct accidental contamination or indirectly when the material has been spilled on the clothing. Using industrial solvents for removing grease and dirt from the hands and arms is a source of dermatitis. Some solvents penetrate the intact skin, get into the blood stream and produce ill effect on the blood and throughout the body nitrobenzene, aniline, phenol, nicotine, etc.

While manufacturing, handling and spraying, pesticides, liquid splashes may enter through skin and cause toxic effects. Vapours of pesticide can enter through nose and solid or liquid pesticide if taken through mouth (unknowingly, accidentally or suicidal) it can pass through digestive route also.

Volatile material like phenol, aniline, nitro benzene, cresol, tetra-ethyl, lead and many organo-phosphorous or organo-chlorine pesticids pose greater hazard through skin than through inhalation. Absorption through lessing of the paidemis is more rapid than through that intact skin. Cut skin may absorb quickly. Therefore safety gloves, aprons, face shield, goggles and overalls are always desirable.

(2) Absorption through Gastrointestinal Tract (GIT) : Used of contaminated and dirty vessels used for eating and drinking is the most common route of ingestion.Contaminated food, drinks, beverages should not be eaten without washing hands and mouth properly. Habit of washing hands and mouth before and after eating, is most desirable. Where it is statutorily required, separate mess-rooms (eating places) are provided (Schedules u/r 102 of the GFR) for this purpose only. Food, drinks, pan-supari, tobacco, lime etc. and smoking are prohibited in workmen.

(3) Absorption through Lungs (Inhalation or respiratory tract): The inhalation of contaminated air is the mist important means by which occupational poisons inter in to the body. Harmful substances may be suspended in the air. in the form dust, fume, mist or vapor and may be mixed with the respired air in the case of true gases. From 8-hour working in a day man breathe about 10 cum of air, Any poisons material present in the respired air offers a serious threats.

Activity Inhalation (Ltr/m)

Resting in bed 06

Sitting 07

Standing 08

Walking (3 km/hr) 14

Working Fast (6 km/hr) 28

Slow run 43

Maximum exertion 65-100

Thus rate of breathing with exertion. good housekeeping, ventilation, local exhaust, ventilation and use of appropriate respirator, while handling toxic substances are primary need.

(4) Injection: This fourth route of entry is direct injection of the material in to the blood stream or the peritoneal cavity of the abdomen or the pleural. cavity surrounding the lung. by a needle it can be inserted in to the skin, muscle or other part of the body. Mostly this route is used to inject material in to laboratory animals. The intervenous injection short circuit protective mechanisms in the body, which resist the material from entering in to blood.

Pre-employment and periodical medical examination of workers expose to toxic hazards, are necessary to detect health effect due to such entry of chemical in human body and to draw inference for engineering and medical safety measures.

Permissible and threshold limit of exposure and dosage:

Various limit values or dosage are assigned to indicate permissible or lethal limit etc.

(1) Permissible exposure Limit:

- Set by OSHA, 29 CFR, 1910.1000, and 1910.1001 through 1910.1450.

- Specify the maximum amount of concentration of a chemical to which a worker may lie exposed.

- Generally define in three different way (Salary limit, Short term expose limit & time weighted average).

(2) Threshold Limit Values (TLVs):

- Prepared by ACGIH volunteer scientists.

- Denotes the level of expositive that nearly all workers can experience with out and unreasonable risk of disease or injury.

- An advisor limit not enforceable by law.

- Generally can be define as selling limit, short term exposure limit and time weighted averages.

- Usually equivalent to PELs.

(3) Excursion Limit (ACGIH)

- Excursion in worker exposure levels exceed 3 times the TLV-TWA for no more than a total thirty minutes during a work day.

(4) Recommeided Exposure Limits (RELs)

- Recommended by NIOSH

- Indicates the concentration of substances to which a worker can be exposure up to a 10 hours work day during a 40 hour work week without adverse effect.

- Based on the animal and human studies.

- Generally expressed as a selling limit, short term exposure limit, or a time weighted average often more conservative then PELs and TLVs.

(5) Workplace Environmental Exposure Limits (WEELs)

- Developed by AIHA volunteers

- Advisor limit not enforceable by law

(6) Company Developed Limits

- Developed by company scientists

- Advisor limit not enforceable by law

- Usually based on only short-term studies of animals.

Below:

(6) Immediately dangerous to Life & Health (IDLH)

- Concentration immediately dangerous to life or health from which a worker could escape without any escape imparing symptom or any irreversible health effect (NIOSH/OSHA)

(7) Tentative Biological Expose Limits & Health weights Limits:

In fact the human organism itself may be regarded as a kind of sampling service. A workers body represent his own individual collector, resistor and monitor of his personal exposure. To arrive at an accurate evaluation of toxic exposure effect limit, Many additional physiological data are nevertheless required. Such as rate of inhalation at quantity of inhaled air/ percentage absorption by the skin and (occasionally) by the intestinal tract, retention rate of metabolism and execreation etc. Therefore the biological exposure (biological monitoring) has been gaining increasing attention recently. The tentative biological exposure limits for the most important toxic substances present in industry have been developed.

The most modern approach is to consider the integral exposure resulting from all modes of entry. (Inhalation, Ingesiton, Skin absorption) Including exposure in the living environment. Adopting this approch WHO (World Health Organisation) study group recently published ‘health based limits’ for occuptional exposure to some common heavy metals.

Work Place or Area Monitoring:

Air monitoring is done for the determination of concentration in the work place area or in the breathing zone of the employee. Air Monitoring can be done for 8-hour, 15 minutes or instantaneous. The result it’s are than compared with exposure indicates such as TLVs, STEL a inhaling limits.

The concentration of the contaminate present in the workplace area is determined by the area air monitor. The purpose of area air monitoring is to identify airborne contamination of the contamination in work case situation. Area air monitor is also use to determine background level of contaminates in a work room. Area air monitoring often is conducted by placing sampling device near contaminant emission areas. Continuous area air monitoring is used to detect fugitive emissions, leaks, ventilation failure, and equipment function before employee exposure occurs.

Hazards of work environment i dude all type hazards affecting work environment and arose due to work itself. Therefore chemical, physical, biological, meteorological factors and hazards of work, working conditions, methods, raw material is, process equipment, process, procedure, waste disposal etc. Should be considered here. First, there permissible exposure limits – prescribed. By law standard or reasonably tolerable – should be found and kept as terget. Then the actual level (existing limit) of all parameters of the working environment should be measured and compared with the target i.e. permissible level and if the measured level is higher than the permissible, the effect should be continued to bring the down to the permissible level. Form No. 37, Rule 12B, GFR is a statutory format in this regard but as it does not dude all work environment (other than air-born contaminants), it should be enlarged to include other work parametre like lev Is of noise, vibration, radiation illumination, temperature, air change, ventilation & waste disposal (pollution parsmetres) etc.

Here the device is placed at targeted work place the area to be monitored.

Biological Monitoring:

Biological monitoring define is the respective and regular measurement and assessment of agents or there metabolites either in the blood, urine, secrete, expired air or combination of these to evaluate exposure and health risk compare to an appropriate reference.

The ersonal air monitoring provide airborne concentrated of air contaminate not necessarily absorption of the contaminate by an expose in the visual biological monitoring has distinct advantage over air measurement, Mainly because it is the absorbed chemical and bio-maker is measured.

Biological Exposure Indices (BETs) are analogues TLV, except for BEIs apply to biological monitoring and TLVs to air monitoring.

Biological or biochemical samples are the blood, urine, fasces, breath (expired air), plasma, body fluid, sweat, hair, nails, saliva etc. They are analyzed

Biological monitoring is not a replacement of any other form of monitoring, It is complementary, work environment monitoring doesn’t give evaluation of individual exposure, Which is given by the biological monitoring.

Useful Information:

Above indicators provide some useful information which can not otherwise be available as under.

- Long term effect of exposure/absorption

- Amount absorbed in body

- Routes of absorption

- Evaluation of total exposure due to work place and out side work environment.

- Amount absorbed due to work place effect, climate factors, age, sex, genetic characteristics, physically effect, condition of organs for bio-transformation and elimination process etc.

- Type and time of risk which can not be provide in any other way.

Medical Monitoring:

Medical monitoring means medical examination by the occupational health doctors of the workers expose to health hazards. Pre, Periodical and post medical examination or monitoring gives better judgement.

Classification of Control Measure:

The control measure can be applied at following three levels:

(1) At Source:

- Substitution toluene in place of benzene, silicon carbide in place of silica in grounding stone, or water in place of solvent.

- Change of process or technology.

- Enclosure of process (cover).

- Isolation (by space or time).

- Wet methods (water blasting).

- Local exhaust ventilation (Capturing at source).

- Waste disposal (pollution control).

- Good maintenance.

(2) At Air path:

- Increasing natural ventilation.

- Providing exhaust ventilation (fans).

- Increasing distance between source and the receiver

- Dilution of mechanical ventilation (Supplied Air)

- Continuous air monitoring (Pre set alarms)

- Good Housekeeping

- Good Maintenance

(3) At Receiver:

- Personal Hygiene methods (Washing, Bathing, Good diet methods, No smoking, Nonintoxicating etc)

- Use of personal protective equipment & good maintenance

- Use of protective cream and loation

- Personal monitoring device (dosimeter)

- Enclosure of worker (AC cabin)

- Rotation of worker

- Training and education

- Medical examination and follow up.

(4) Engineering Control:

In this category are included those procedures which are applied to the working environment rather than to individual.

- Substitution and Modification: The highly toxic material (carcinogenic, motagenic or teratogenic) & process should be replace by less hazardous materials. Precaution required by while selecting safer substitute is that it should not being any new hazards. Modification in the process and equipment can reduce the hazard reduction in noise, vibration, excessive light and temperature, speed, grinding and mixing of speed, mechanical handling in stated of manual, use of tonge instead of fingers, sitting posture instead of long standing etc. Help in decreasing the health effects.

- Isolation and enclosure of process: This has its widest application in the chemical industries where frequently it is possible and practicable to design totally enclosed systems for carrying out the manufacture and processing of chemical compound. Enclosure may be total or partial close system, barrier walls, cabins and isolation by distance and time by possible.

- Segregation: This is perhaps the most engineering control measure. Ventilation may be general or local, General ventilation consist in rapid dilution of contaminated air with fresh air usually by fan. Local ventilation usually consist in providing air suction close to the point, where potentially harmful dusts, fumes, vapours, mist or gases are generated.

- Wet Process: The use of water to limit the dispersal of atmospheric contaminates finds its chief application in the control of dust. This procedure is widely used in rock drilling and useful when sweeping is done in a dusty work room.

- Sampling and Monitoring: It is important to conduct regular appraisals of the working environments by means of dust counts, air sampling and analysis and similar test there by checking the effectiveness of the preventive measures.