Industrial toxicology is the scientific and systematic study of poisonous substances or toxics with reference to industries. In industries the workmen may have to face chemical hazards of toxic nature in their work places. The toxic effect may be fatal or may impair or damage the human system in the long-run through cumulative action.

The toxic of substances depends on the degree of exposure. In general the degree of exposure depends upon the time of exposure, the concentration of toxic substance as well as the susceptibility of the workers to a particular toxic chemical. Toxic may find entry into the human system broadly in a four-fold manner:

- Through absorption by skin.

- Through the respiratory system by inhalation.

- Through the gastro-intestinal tract by swallowing.

- Through other organs like eyes etc.

Contents

Effect of toxic substances on the human system

Effects of toxic substances so far as their degree of danger, sphere of action and exposure-periods are concerned may be expressed by using suitable terms. The degree of danger associated with a toxic chemical may be expressed as serious, moderate or mild. Depending upon the severity of the toxicity hazard.

The sphere of action associated with a toxic chemical may be expressed as local or systemic. A particular part of the body say eyes may be affected due to exposure of eye to ammonia. This is an example of local effect, whereas lead poisoning affecting blood forming cells, bones and nervous system is an example of systemic effects.

The exposure- period associated with a toxic chemical may be instantaneous or prolonged in respect of time. Injured of limbs by corrosives like nitric acid is an example of instantaneous cases, whereas silicosis resulting from inhalation of silica dust over a long period of exposure is an example of prolonged case.

Factors influencing the Effects of toxic Materials

The effects of toxic substances on the workmen depend upon the following considerations:

- Absorption. The effects are dependent upon the rate of absorption of toxic substances in the human body. Quicker the absorption more is the risk to the workmen.

- Concentration and time of Exposure. More the concentration and time of exposure more is the amount of toxic substances getting entry into the human body.

- Personal tolerance level. Certain persons can reasonably tolerate a particular toxic substance while others cannot.

- Susceptibility. Susceptibility to toxic substance may vary from person to person.

- Personal hygiene and behaviour. Personal hygiene and behaviour including proper maintenance of clothing, cleanliness, tidy habits etc. play an important role as regards the effects of toxic substances on the human system.

- The state of the matter. The state of the matter of toxic substances (whether solid, liquids or gases) play an important role in connection with the effects of toxic substances on the human system. As for example hydrochloric acid HCI as (liquid) stored in container will be much less disturbing as compared to an atmosphere charged with hydrogen chloride (HCI) in the gaseous state.

The following are the term related to concentration-levels as per industrial hygiene norms:

- Maximum allowable concentration. Maximum allowable concentration is abbreviated as MAC. MAC is the concentration of toxic substances which must not be exceeded or violated even for a very short period of time.

- Ceiling value. Ceiling value is generally designated by C. Ceiling value is the maximum value of concentration of a toxic substance which should not be exceeded for certain chemicals only.

- Threshold Limit Value. It is abbreviation as TLV. Threshold limit value is the maximum concentration of a toxic material which the workmen can tolerate or withstand for 8 hours a day while working in the atmosphere charged with the contaminant. It is to be noted that in case of concentrations of varying nature a time weighted average (TWA) may be computed.

- Short term exposure Limits. It is abbreviated as STEL. It is the concentration of a toxic substances which can be tolerated by workmen for 15 minutes without causing any adverse effects e.g. irritation, tissue changes etc.

All above terms (i.e., MAC/TLV/C/STEL) relate to normal conditions i.e. adults and non-susceptible cases.

Units of concentration

Concentration may be expressed in P.P.M. (part per million) as well as in mg/M3 for gases, vapours and liquids, whereas in case of solids (including solid particulates, salts, dust and fumes) concentration may be expressed in mg/M3 . in case of fine particles the concentration can also be expressed in mppcm (million particles per cubic metre). It is to be noted that the units for TLV, MAC, STEL, TWA and C are the same as the units of concentration stated above.

Various data and literatures on industrial hygiene have been compiled and prepared throughout the world notably in the countries like USA, UK etc. these throw light on the state-of-the art position/Knowledge of the various aspects of industrial toxicology. These data etc. may not be exactly uniform but serve as a reasonably good guide or basis for future research/investigations on the subject. These data or values are somewhat flexible in nature and call for periodical reviewing and updating.

Studies pertaining to the effects of toxic materials on the human system are based on the following:

- Observations on human volunteers.

- Observations on animals e.g. guinea pigs etc.

- Determining the concentration of contaminants in the work atmosphere.

- Reconstruction of fresh and updated data from the available results of exposure to contaminants along with known cases of occupational diseases.

Management of workplace exposures

Management of workplace exposure consists of a stepwise and systemic exercise to co-ordinate all the action areas. The action areas of the management comprises of the following.

- Preliminary information, collection of data and subsequent analysis regarding all aspects of toxic materials and the work force of the industry. This may include names of the hazardous chemicals, their toxicity, safety provisions, flow-charts of various processes etc. basically this amounts to a thorough office-work.

- Field work consisting of reconnaissance surveys at sites and to get information on the spot from direct contacts with the work force and the managers. This forms the backbone of the particle information regarding the working the working conditions and the environment as well as that of the control systems used in the particular industry.

- The next step consists of study and assessment of the environment notably air pollution. This monitoring process takes into its ambit the identification, evaluation, protective and remedial measures as well as measurementof toxic materials in the general environment of the workplace. This environment monitoring calls for thorough surveillance coupled with taking measurement (by using suitable measuring devices) to detect and quantify the contaminants. Sampling instruments or accessories are used to measure the concentration of the contaminants. Some of the sampling or measuring instruments are as follows:

- Midget impingers.

- Thermal precipitators.

- Electrostatics precipitators.

- Soluble and non-soluble contaminant collectors.

- Another important step is to assess or monitor the health status of the workforce exposed to the contaminants. The biological effects of contaminant on the persons can be gauged through medical capacity test, audiometric tests etc.

- After all the steps as mentioned above are complete, a final report comprising of findings, investigations, monitoring, suggestions, remedialmeasures etc. may be prepared which will reveal the whole scenario of the management of workplace exposure.

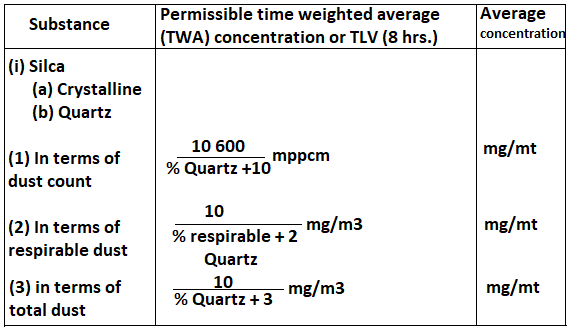

Examples of (threshold Limit Values TLV or time- weighted Average Value TWA) and short-term Exposure Limit (STEL) value of certain substances.

[For details please refer to the Second Schedule (Section 41 F) of the Factories Act, 1948].

Permissible levels of certain chemical substances in work environment

| Solids(including salts, fumes and dust) | PPM | Mg/m3 | PPM | Mg/m3 |

| Calcium oxide | 2 | – | ||

| Cotton dust raw | 0.2 | 0.6 | ||

| D.D.T. (Dichloro-diphenyl trichloroethane) | 1 | 3 | ||

| Lead inorg. Fumes and dust (as Pb) | 0.15 | 0.45 | ||

| Phosphorus (Yellow) | 0.1 | 0.3 | ||

| Cadmium- dust & salts (as Cd) | 0.05 | 0.2 | ||

| Copper fume | 0.2 | – | ||

| Chromous salts (as Cr) | 0.05 | – | ||

| Manganese fume | 1 | 0.3 | ||

| sodium hydroxide | C2 | – | ||

| manganese (as Mn) dust & compounds | C05 | – | ||

| Gases, Vapours & liquids | ||||

| Acetic acid | 10 | 25 | 15 | 35 |

| Ammonia | 0.25 | 18 | 35 | 27 |

| Benzene | 10 | 20 | 25 | 75 |

| Bromine | 0.1 | 0.7 | 0.3 | 2 |

| Carbon monoxide | 50 | 40 | 400 | 440 |

| Carbonyl chloride (phosgene gas) | 0.1 | 0.4 | – | – |

| chlorine | 1 | 3 | 3 | 9 |

| chloroform | 10 | 50 | 50 | 225 |

| Ethyl alcohol | 1000 | 1900 | – | |

| Flourine | 1 | 2 | 2 | 4 |

| Formic acid | 5 | 9 | – | |

| Gasoline | 300 | 900 | 500 | 1500 |

| Methyl isocyanate(methanol-skin) | 200 | 260 | 250 | 310 |

| Methyl isocyanate | 0.02 | 0.05 | – | – |

| Nitric acid | 2 | 5 | 4 | 10 |

| Nitric oxide | 3 | 6 | 5 | 10 |

| Phenol – skid | 5 | 19 | 10 | 38 |

| Phosphine | 0.3 | 0.4 | 1 | 1 |

| Sulphur dioxide | 2 | 5 | 5 | 10 |

| n-Butyl alcohol (skin) | C50 | C150 | – | |

| Hydrogen chloride | C5 | C7 | – | |

| Hydrogen cyanide (skin) | C10 | C10 | – | |

| Iodine | C 0.1 | C 1 | – | – |

Notes:

- C denotes ceiling limit or ceiling value.

- Not more than four times a day at least 60 min interval between successive exposures.

- Mg/m3 milligram of substance per cubic meter of air.

- p.p.m. parts of gas or

vapour per million parts of contaminated air by volume at 250 C and 760 mm of Hg (i.e. a Pressure of 1 atmosphere). - Mg/m3 = molecular weight/24.45x p.p.m…

- The value of STEL is intermediate between TLV and MAC. To cite one example the value of TLV for ammonia is 0.25 p.p.m. and the value of MAC for ammonia is 37.5 p.p.m. whereas the value of STEL for ammonia is 35 p.p.m. (which is an intermediate value and lies between TLV and MAC values).

Some toxic chemicals and their harmful effect on human system

- Carbon monoxide. Carbon monoxide on inhalation causes asphyxia or breathlessness. In high concentrations carbon monoxide can also cause death.

- Carbon disulphide. On inhalation causes anaesthetic effects. Central nervous system is also affected on prolonged exposure to carbon disulphide.

- Chlorine. Inhalation causes irritation to mucous membranes i.e. eye, nose etc. it can cause death if the concentration is high.

- Chromium. Chromium entering the body through inhalation or taking of food and water contaminated with chromium compounds can cause ulcers as well as cancer of certain vital organs of the body as for example lungs etc.

- Mercury. Mercury and its compounds can cause adverse effects on the central nervous system of the human body.

- Lead. Lead poisoning badly affects the central nervous system as well as bones.

- Naphtha. Naptha on inhalation can cause breathlessness or even coma.

- Methyl isocyanate. It can affect the respiratory as well as gastro intestinal tract. Methyl isocyanate poisoning is characterized by serious irritation of eyes etc. it can prove fatal in high concentrations.

- Sulphur dioxide. Sulphur dioxide if inhaled causes irritation of throat, nose etc. and can even cause death in substantially high concentrations.

- Phosgene. Phosgene if inhaled seriously affects the respiratory system etc. And can cause death in case of high exposures.

Thank You for reading Industrial toxicology article. if you like please this.