Contents

Some common types of scaffolding are as follows:

- Single pole (standard) type scaffolding (Putlog Scaffold)

- Double pole (standard) type scaffolding (Independent Scaffold)

- Rolling Scaffolding, Trestle, Mobile Towers, Patented Scaffolding (Mobile Scaffold)

- Outrigger Scaffolding

- Swinging (Hanging) Scaffolding

- Suspended Scaffolding

- Boatswain’s Chair

Single pole type scaffolding (Putlog Scaffold)

The upright (vertical poles/Standard) should rest on a strong foundation to support the load without a settlement. They should not be kept more than 3 meters apart.

CLICK HERE FOR > SCAFFOLDING CAPACITY

CLICK HERE FOR > JSA

CLICK HERE FOR > HIRA

CLICK HERE FOR > SAFETY PLAN

CLICK HERE FOR > MONSOON SAFETY PLAN

CLICK HERE FOR > COVID-19 SAFETY PLAN

Tubular uprights have steel base plates placed on wooden/steel sole plates. Soft ground should be well rammed and leveled.

Fixing like steel bolts, nails of fiber rope of approved size, joint pins and couplers should be properly fitted. For load-bearing right-angled or swivel, couplers must be used.

Putlog couplers are useful for putlog members only. Putlog members (horizontal, ledger) must be at least 10-20 cm be inserted in the wall. Bracing (diagonal connection) must be tied to ensure structural stability and prevent buckling.

CLICK HERE FOR 👉 SCAFFOLDING NEAR MISS

To prevent overturning the scaffold should be secured at intervals not greater than 7.6 m vertically and horizontally.

Double pole (standard) type scaffolding (Independent Scaffold)

This is an independent scaffold without any support of other structures/walls.

Rolling Scaffolding, Trestle, Mobile Towers, Patented Scaffolding (Mobile Scaffold)

Such scaffolds move on rollers (wheels) or castors with wheel locking device. They are portable and most useful for maintenance.

To prevent overturning, height should not be more than three times the minimum width of the base. The minimum base length should be 4 feet.

CLICK HERE FOR 👉 WORK AT HEIGHT

While pushing or pulling the tower, persons should not ride/work on it. Tools and materials should be removed before moving.

The top working platform must have handrails and toe guard/board. It should support a 30 lb/ft2 distributed the load.

The rigidity of the tower is secured by diagonal bracing on all four sides and on the plan. Moving the tower scaffolding by pulling at the top or leaning sideways should be avoided.

Rolling or mobile tower scaffold is shown below.

Outrigger Scaffolding

It is a balcony type cantilever scaffold resting on the wall. If other types of the scaffold are possible, this type should not be used.

The outriggers should be passed right through the wall and be secured on the inner side. Supporting hook between brick joints is dangerous.

CLICK HERE FOR 👉 HIRA

The platform should not project beyond 2 meters from the wall. Guard rail and toe board should be provided.

Swinging (Hanging) Scaffolding

Here the platform is hanging by two chain pully blokes, ropes and hooks on supporting beam. The suspended platform can be raised or lowered as per need.

The movement of both ends should be simultaneous. The anchorage and the suspension gear should be strong enough to withstand the load with good factors of safety.

Suspension ropes should withstand 6 times (safety factor 6) the intended load. Rope diameter shall be more than 0.75 inches.

A safety rope shall be provided in addition to the suspension ropes.

The width of the platform must have more than 50 cm and less than 90 cm. Guard rails and toe boards/guard necessary on all t sides open. The platform must be lashed or secured while in use to prevent swaying.

Each person working on a swinging scaffold should wear Full body safety harness with a lifeline attached to an anchorage other than the scaffold itself.

Lifeline must be able to carry a minimum weight of 2268 kg.

Suspended Scaffolds

Two or more platforms are suspended by ropes from overhead outriggers anchored to the building.

Such scaffolds are designed with a factor of safety 4 and shall never be overloaded. Anchor plates should be tied with U bolts. Counterweights are used to prevent overturning. Wire ropes (FS 6) are used to support scaffold.

CLICK HERE FOR 👉 EXCAVATION SAFETY

Hoisting drum (like winch) is used with at least 2 dead turns. The gap between the handrail and toe board should be covered by a wire mesh of 38 mm and 16 gauge wire. Overhead protection should be provided if the risk of falling objects is possible.

Boatswain’s Chair

Boatswain’s Chair is used for supporting and hoisting a single person in a sitting position. General Chair (seat) size is 60 cm × 30 cm, with 25 mm thick timber. Cleats extending in front to at least 23 cm should be securely fixed under the chair at both ends.

The chair is supported by a suitable sling passing through the four corner holes in the chair for proper stability. The suspension rope is fixed to overhead support or passed through a pully block fastened to such support.

CLICK HERE FOR 👉 SAFE WORKING LOAD

The free end is secured to a conveniently accessible anchorage and the person in the chair must wear a safety belt, the lifeline of which is secured to the tackle supporting the chair, Fibre rope slings should not be used if the person in the chair has to do welding or cutting work.

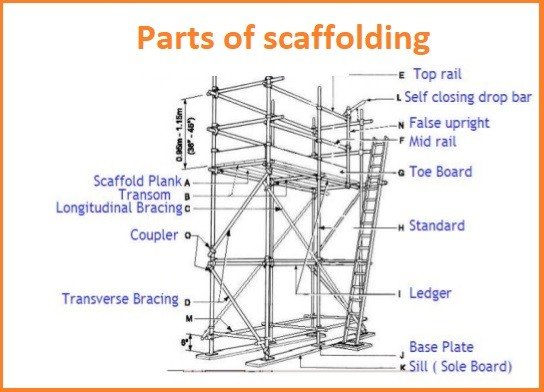

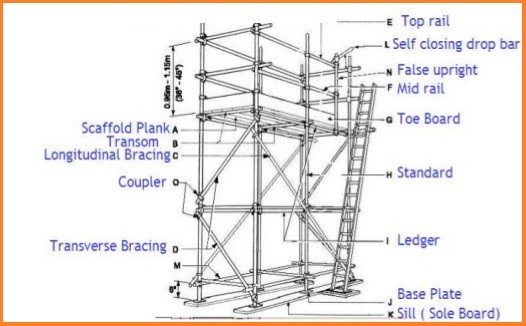

Types of scaffolding components/Parts of scaffolding

SCAFFOLDING PARTS

- Sole-plate

- Scaffolding Tube

- Scaffolding Clamps/Couplers

- Base Plate

- Scaffolding Planks

- Toe Board

Scaffolding Tube

Scaffolding Clamps/Couplers

Base Plate

Scaffolding Planks

Toe Board

Also, read this:

People also search for

- Types of scaffolding in India

- Types of scaffolding Uk

- Classification of scaffolding

- Three types of scaffolding

- Scaffolding parts name with pictures pdf

- Parts of scaffolding

- Scaffolding Parts Name

PLEASE SHARE THIS ARTICLE WITH YOUR FRIENDS

Solluz energy is a leading solar panel company in india. We deliver sustainable energy solutions with top-notch installations and maintenance services. Our mission is to harness solar power for a greener, brighter future. Join us in powering progress with clean, renewable energy! Solar Panel Company in India Retail Store Fixtures

Fabtro Technologies is an expert in heavy sheet metal fabrication, providing robust and high-quality construction for industrial applications. Our precision engineering ensures durability and strength for all your heavy-duty needs.

Thanks for sharing this site.

Hi, Kindly send me the relevant HSE topics for further enhancing my skills in the field.

Good bro

Sir if u have a presentation on investigation techniques plz share or send me through mail