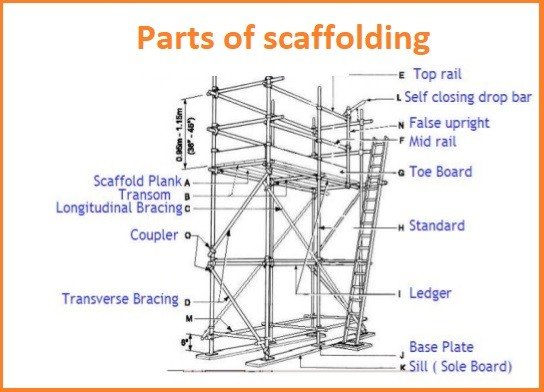

Scaffolding is a basic requirement in construction and maintenance work, providing a temporary structure that supports workers and materials during the construction and maintenance. Various parts of scaffolding are important for ensuring safety, stability, and efficiency of scaffolding at construction sites. In this article, we will discuss about all parts of scaffolding and their roles in creating a secure and functional scaffold platform for construction and maintenance activities.

Contents

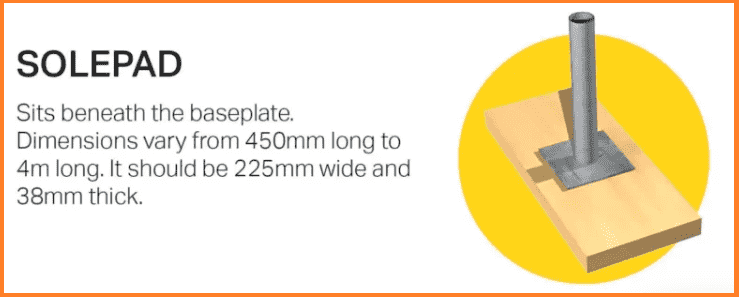

1. Sole Plate/Board

The sole plate is an essential component because it helps distribute the weight of the scaffold and its occupants, providing stability and preventing the structure from sinking into the ground.

Key points about the sole plate in scaffolding:

- Material: Sole plates are often made of steel or timber. The choice of material depends on factors such as the type of scaffold, load-bearing requirements, and environmental conditions.

- Placement: Sole plates are positioned at the base of each scaffold leg, creating a stable platform for the entire structure. They distribute the load evenly and help prevent the scaffold from sinking into soft or uneven ground.

- Size and Dimensions: The size and dimensions of sole plates can vary depending on the type of scaffold and the specific requirements of the job. They are typically designed to provide adequate support and stability (commonly use 300 x 300 mm.)

- Adjustability: Some scaffolding systems allow for the adjustment of sole plate height to accommodate uneven ground or changes in elevation. This is particularly important for ensuring a level and stable scaffold platform.

- Connection to Standards: Scaffold standards or vertical members are connected to the sole plates. This connection is crucial for transferring the load from the scaffold to the ground through the sole plates.

- Load-Bearing Capacity: The sole plate must have sufficient load-bearing capacity to support the weight of the scaffold, workers, and any equipment or materials being used on the platform.

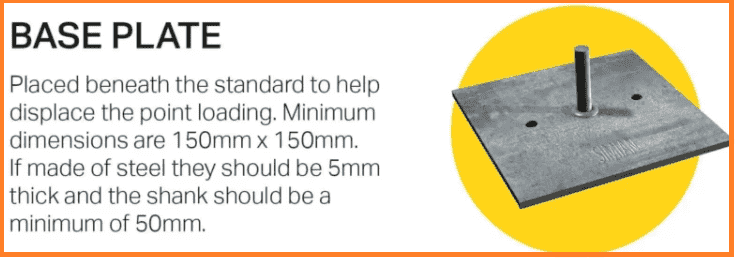

2. Base plate

In scaffolding, a base plate is a crucial component that forms the bottom support of the scaffold structure. Base plates are typically attached to the ends of the vertical scaffold standards or uprights and serve several important purposes:

- Load Distribution: Base plates help distribute the load of the scaffold evenly onto the supporting surface. They provide a broader area of contact with the ground, reducing the pressure on the underlying surface and preventing the scaffold from sinking into soft or uneven ground.

- Stability: Base plates enhance the stability of the scaffold by providing a secure and level foundation. They prevent the scaffold from tilting or leaning, especially on surfaces that may not be perfectly flat.

- Connection with Sole Plates: Base plates are often used in conjunction with sole plates. The sole plate is the horizontal member that rests directly on the ground, and the base plate is attached to the bottom end of the scaffold standard, connecting it to the sole plate. This connection ensures that the load is transferred from the scaffold to the ground through the base and sole plates.

- Adjustability: Some base plates are designed to be adjustable in height. This feature allows for fine-tuning the scaffold’s level on uneven surfaces. Adjustability is especially important for ensuring the stability and safety of the scaffold.

3. Standards (Uprights)

Standards, also known as uprights or verticals, are the vertical tubes that form the main framework of the scaffolding. These components bear the load and provide vertical support for the entire structure. They are typically connected to the base plates, which distribute the weight evenly and anchor the scaffolding to the ground.

4. Ledgers (Horizontal Tubes)

Ledgers are horizontal tubes that connect between the standards. They help in distributing the load and providing lateral support to the scaffold. Ledgers are positioned parallel to the building’s facade and play a crucial role in maintaining the overall stability of the structure.

5. Transoms

Transoms are horizontal members that are placed perpendicular to the ledgers. They add further strength and support to the scaffold structure, enhancing its load-bearing capacity. Transoms are especially important for supporting the scaffold boards or platforms where workers stand or place materials.

6. Transverse bracing

Horizontal diagonal members or braces that are used to provide lateral stability and prevent the scaffold structure from swaying or collapsing.

Purpose of Transverse Bracing:

- Lateral Stability: Transverse bracing helps to stabilize the scaffold laterally, preventing it from tipping over or swaying sideways.

- Enhanced Rigidity: By connecting the vertical posts (standards) of the scaffold with horizontal braces, transverse bracing increases the overall rigidity of the structure.

7. Diagonal Braces/longitudinal brace

Diagonal braces are inclined tubes that connect between standards and ledgers, forming an X-shape. These braces are essential for enhancing the rigidity and stability of the scaffolding. They prevent swaying or leaning and ensure that the structure can withstand lateral forces, such as wind.

8. Ladder

Ladders are an integral part of scaffolding systems, providing safe and convenient access to different levels of the scaffold. adders should be securely attached to the scaffold, and users should follow proper climbing techniques. Additionally, guardrails and other fall protection measures are often in place to prevent accidents.

Ladders in scaffolding are typically made of materials such as aluminum or steel to provide strength and durability. The material chosen depends on factors like the load capacity required and the environmental conditions.

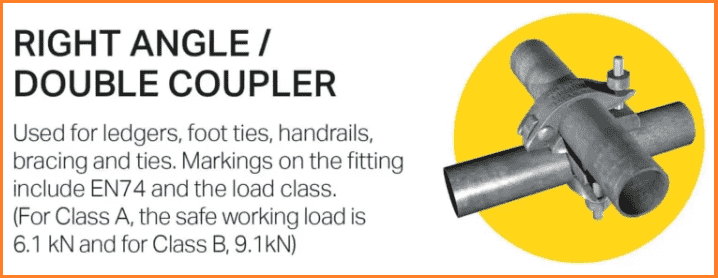

9. Couplers/Clamp used in scaffolding

In scaffolding, couplers and clamps are essential components that connect different scaffold tubes or members to create a stable and secure structure. There are various types of couplers and clamps designed for specific purposes in scaffolding. Here are some common types:

Swivel Couplers (Double Couplers):

Connects two scaffold tubes at any angle. Consists of two halves that can swivel to accommodate different angles.

Right Angle Couplers (Putlog Couplers):

Used to connect tubes at right angles, Often used to attach putlogs or transoms to ledgers.

Sleeve Couplers:

Connects two scaffold tubes end-to-end, also known as joint pin or external sleeve.

Putlog Couplers (Single Couplers):

Connects a single tube to a ledger or transom, Typically used to support scaffold boards.

Board Retaining Couplers:

Holds scaffold boards in place, prevents boards from slipping or moving.

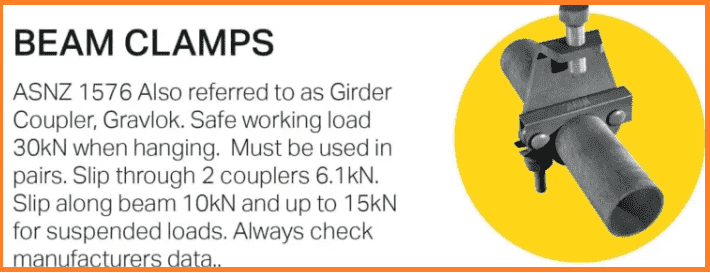

Beam Couplers:

Similar to girder couplers, used to connect scaffold tubes to beams or other horizontal members.

Spigot Pin:

10. Scaffold Boards (Planks)

Scaffold boards, also known as planks, are the platforms on which workers stand and place their tools and materials. These boards are typically made of wood or metal and should be strong enough to support the intended load. Proper installation and secure fastening of scaffold boards are critical for the safety of workers.

11. Guardrails and Toe boards

Guardrails:

- Purpose: Guardrails are horizontal or vertical barriers that surround the open sides of a scaffold platform. They serve as a protective barrier to prevent workers from accidentally falling off the edge of the platform.

- Requirements:

- The top edge of the guardrail should be between 38 inches (97 cm) and 45 inches (114 cm) above the scaffold platform.

- There should be a midrail installed halfway between the top rail and the platform surface.

Toe boards:

Purpose: Toeboards are installed along the edge of a scaffold platform to prevent tools, equipment, or other materials from falling off the platform and posing a hazard to workers below.

- Requirements:

- Toe boards are typically required on all open sides of scaffolding platforms.

- They are usually installed along the outer edge of the scaffold platform and are securely attached to the guardrails.

- Toeboards should be able to withstand a certain amount of force to prevent objects from falling.

12. Drop door / self-closing door in scaffolding

A “drop door” or “self-closing gate” in scaffolding refers to an access point or entryway on a scaffold platform that is designed to close automatically after a person passes through it. This feature is part of the overall safety measures implemented in scaffolding systems to prevent accidental falls or unauthorized access. Here’s a brief overview:

Purpose:

- The drop door or self-closing gate serves as an entry and exit point on a scaffold platform.

- Its primary purpose is to provide convenient access for workers while minimizing the risk of leaving openings unsecured.

Frequently asked questions (FAQ) for scaffolding parts names:

Q1: What is scaffolding? Scaffolding is a temporary structure used in construction, maintenance, and repair work to provide a platform for workers and materials.

Q2: What are the main components of scaffolding? The main components include standards (upright posts), ledgers (horizontal braces), transoms (horizontal crossbars), scaffold boards, base plates, and couplers.

Q3: What are standards in scaffolding? Standards are vertical posts that provide the vertical support for the scaffold. They are connected to the base plates at the bottom and reach the required height.

Q4: What are ledgers and transoms? Ledgers are horizontal braces that connect the standards horizontally, providing lateral support. Transoms are horizontal crossbars that run perpendicular to the ledgers, further strengthening the scaffold structure.

Q5: What are scaffold boards? Scaffold boards are the planks or platforms where workers stand or place materials. They rest on the ledgers and transoms, forming the working surface.

Q6: What are base plates in scaffolding? Base plates are flat plates placed under the standards to provide stability and distribute the load evenly on the ground or supporting surface.

Q7: What are couplers in scaffolding? Couplers are fittings that connect different scaffold components, such as standards to ledgers or transoms, providing a secure and stable connection.

Q8: What are guardrails in scaffolding? Guardrails are safety barriers attached to the scaffold structure to prevent workers from falling.

Q9: What is a toe board? A toe board is a barrier attached to the scaffold boards at the edge to prevent tools or materials from falling off the platform.

Q10: How is scaffolding assembled and disassembled? Scaffolding is assembled by connecting standards, ledgers, transoms, and other components using couplers. It is disassembled in the reverse order, starting from the top.

Q11: What are the different types of scaffolding? Common types include tube and coupler scaffolding, frame scaffolding, and modular scaffolding systems like ring lock and cup lock scaffolding.

Q12: How is scaffolding inspected for safety? Scaffolding should be inspected regularly for any damage, proper assembly, and adherence to safety standards. Inspections are typically conducted by competent personnel before each use.

These are just a few common questions regarding scaffolding parts and their names. If you have more specific questions or need detailed information about a particular aspect, feel free to ask!