Lifting tackles and tools, gear or appliance means fiber rope sling, wire rope sling, chain slings, hooks, rings, sheaves (grooved pulleys), swivel, shackles and similar gears.

Ropes: Generally manila and PP ropes are used in hoisting, lowering and handling operations. There are various grades of ropes and therefore while purchasing their guaranteed breaking strength should be obtained from the manufacturer in order to assess the safe working loads of the ropes.

Fiber rope is very susceptible to mechanical damage and they should, therefore, be frequently inspected for their strength. Particular care is necessary when it is suspected that the rope may have been contaminated by chemical action.

A fiber rope of less than 12 mm dia should not be used for a sling or a lifting device. For ropes, the safe working load can be calculated by dividing the minimum breaking load quoted by the manufacturer by a factor of safety depending on the use.

Read: Safe working load (SWL) and safety factor

Periodical inspection of the whole length of rope is necessary to detect broken wires, amount of wear, corrosion, rust, etc. Broken wires in a rope must always be regarded as a warning sign. Wire ropes must not be knotted. They should be joined solacing.

For the same working load, the chain sling is 5 to 8 times as heavy as wire rope but it has a longer life, stands up better rough use and is almost 100% flexible. The chain is obtainable in many grades like wrought iron, mild steel, high tensile steel, and alloy steel. Wrought chains require to be periodically heat-treated to remove brittleness.

While using a sling the ratio of the load lifted by any leg of the sling is inversely proportional to the number of legs. For example, when a 2-ton load is lifted by directly hooking to the chain or cable, the load on the line is 2 tons. But if it is hooked to a two-legged sling the leg of each sling carries 1 ton (while the line connected to the sling holds 2 tons). If it’s a four-legged sling, each leg carries 0.5 ton.

The stress in any leg increases as the angle of the leg with the horizontal decreases. In the two-legged sling, each leg carries stress equal to the total load when the angle is 30° and stress of nearly six times the load when the angle is 5°. Therefore it is important to keep the angle as large as possible and the stresses are computed carefully to maintain a reasonable safety factor.

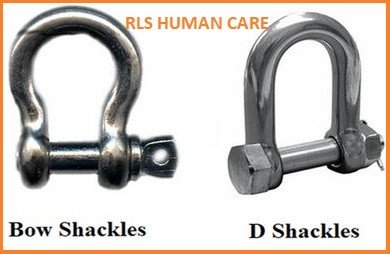

The hook is either of a circular section or trapezoidal. The former is meant for light loads up to 5 tons. Shackles according to the difference in shapes are known respectively as D and Bow shackles.

The pins are usually of circular section. The methods of securing shackle pins in positions vary according to the nature of the use of the shackles. When there is a risk of the pin coming out, pins are secured by means of a nut and a cotter pin. A cotter pin affords more rigidity than a plain pin.

All sling, rings, hooks, shackles, swivels, couplings, sockets, etc., should be as per Indian Standards. Permissible working load of one leg should be calculation from the ready table of sling diameter and varying angles between two legs.

Also, read this:

Safety in rigging and erection

Great article.

Also dont forget to click on the links to get more information about

load testing certification

Load Testing Services in India

load testing services

load testing certification

Great article.

Loved the content.

Also dont forget to click on the links to get more information about

load testing certification

Load Testing Services in India

load testing services

load testing certification