Contents

THE NEED FOR NDT

Visual observations, even with magnification, cannot locate all small, below the surface defects in the cast, forged metals or in weld -metals such as found in pressure vessels, boilers, and nuclear components. Proper NDT will, however, revel, all such indications, without damage to the components.

Non destructive testing methods

THE TYPES OF NDT

- Magnetic particle.

- Penetrant.

- Ultrasonic.

- Electromagnetic.

- Radiographic.

Magnetic Particle Test in NDT

MP inspection test is the most common use test non destructive testing methods for forgings. It utilizes magnetism to attract and hold very fine magnetic particles right on the part itself. If a defect present, it interrupts the magnetic field and is clearly shown by the pattern made by the particles.

The part is magnetized in a suitable direction by DC line voltages transformed to low voltage (4 to 18 volts) high amperage AC, half wave current, or three phases full wave current.

CLICK HERE FOR > HYDRO TESTING SAFETY

SAFETY PRECAUTIONS of Magnetic Particle Test:

- All electric circuits should be installed and grounded according to National Electrical Code or any other appropriate code.

- Local exhaust should be provided to control the dust particles used for testing.

- If the local exhaust is not feasible, the operator should wear respiratory protective equipment.

- Eye protection should be worn by the operator to guard against the irritating effects of dust particles and arcing.

- Personal protective equipment should be worn to protect against the possible skin irritation from the powder.

CLICK HERE FOR 👉 PPE IN DETAILS

CLICK HERE FOR 👉 ALL PPE IS CODE

Penetrant Inspection (DP) in NDT test:

DP tests are used for detecting cracks, pores and similar indications which are open to the surface in metals or other solid material.

First, the part to be inspected is cleaned a penetrant is then applied to the surface and within a few minutes is drawn into defects by capillary action. The penetrant is removed from the surface but will remain in the surface opening until removed by the developer.

SAFETY PRECAUTIONS in Penetrant Inspection (DP)

- Most penetrants are organic compounds that may cause dermatitis.

- Skin contact should be avoided with good personal hygiene practices strictly followed.

- Smoking, smoking materials, food or drinks should not be stored or used in the test area.

- Exposed skin should be washed before smoking, eating or drinking.

Ultrasonic Tests (UT) in NDT:

Ultrasonic waves (above the audible range of 20,000 Hz is created by an electronic generator which supplies high-frequency voltage to a piezoelectric crystal.

Three basic ultrasonic methods have been developed. The reflection method the through transmission method and the resonance frequency method.

SAFETY PRECAUTIONS in Ultrasonic Tests (UT)

- Equipment should be disconnected from the power supply and

- The condensers discharged whenever a cathode ray tube must be adjusted or removed.

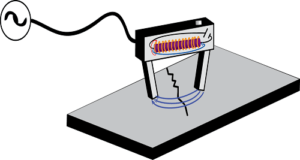

Electromagnetic non destructive testing methods in NDT:

Two types of electromagnetic tests are currently used: magneto-inductive and eddy current.

The magneto-inductive method uses variations in the permeability of magnetic materials to create variations in a pickup coil or probe.

The eddy current utilizes alternating current in a coil or probe to induce an eddy current in the part being tested. Defects and variation in properties or geometry cause changes in the strength and distribution in the eddy current.

The readout is presented on a cathode ray tube, on a meter, by a suitable or by visible alarm, or by a combination of these methods.

SAFETY PRECAUTIONS:

- In some reader frequency testing installations, operators have been burnt internally, when they passed between the object and the testing device. Special regulations should be formulated and enforced.

- Barriers should be set up to prevent operators and others from entering such areas.

- Recommendations of the manufacturer of the equipment should be followed explicitly.

Radiography Tests in NDT:

Radiography uses X rays and gamma rays. X rays are unidirectional and their wavelengths can be varied within certain limits, to suit the conditions Gamma radiography differs from the X-ray radiography, in that the gamma rays are multidirectional and their wavelengths, being characteristic of the source, cannot be regulated.

CLICK HERE FOR 👉 PROCEDURE FOR RADIOGRAPHY EXAMINATION

CLICK HERE FOR 👉 RADIATION SAFETY IN DETAILS

CLICK HERE FOR 👉 Radiation Protection Rules

SAFETY PRECAUTIONS Radiography Tests:

- All sources of ionizing radiations are potentially dangerous They should be stored and handled in accordance with the instructions of the supplier of the source.

- The exposure to the radiation by the operators should be regularly monitored, in accordance with the supplier s instructions.

- The only trained and certified operator should be allowed to do the work.

- The surrounding area should be effectively cordoned off and ensured that no one enters this area.

- Where-ever possible, the work should be done in a suitable enclosed room, built in accordance with the supplier of the source.

- All operators should be medically examined at frequency suggested by the supplier of the source.

- After the work is over, the source should be stored in accordance with the instruction of the supplier of the source.

Also read this:

- Safety in welding and cutting

- Flashback/Backfire safety in gas cutting

- Hydro testing safety

- Radiography Safety in Construction

Now it’s your turn:

You are reading at rlshumancare.com. Do not forget the name RLS HUMAN CARE. Please share with your friends and help RLS HUMAN CARE. Thank You!!

very good.

This is Mr. Rafiq Nayak HSE Export working in ircon international national

Very nice

I like and where are u now

Very good sir

Any branch in uae

No

Vidalndt is the best ndt training institute in vijayawada to offer level 1,2,QA & QC course in 45 days with well equipped lab & Placements in India and Abroad program NDT Training in Hyderabad NDT Training in Vijayawada and thank you for safety instruction for ndt profestion…..