Contents

What is Industrial Radiography

Industrial radiography is a non-destructive testing method that uses ionizing radiation to inspect the internal structure of an object. The object is placed between a source of ionizing radiation, usually an X-ray or gamma-ray machine, and a detector that captures the radiation that passes through the object.

The captured image, known as a radiograph, shows the internal structure of the object, including any defects, such as cracks or voids, that may be present. Industrial radiography is commonly used in the manufacturing and maintenance of critical components in industries such as aerospace, automotive, construction, and power generation.

The use of industrial radiography requires specialized training and equipment to ensure the safety of personnel and the environment. Strict regulations and guidelines are in place to ensure that the use of ionizing radiation is carried out safely and effectively.

- Uses a radioactive source or energy to produce a radiograph.

- Ionizing radiation can penetrate objects and create images on photographic film.

- The technique is called radiography and the processed films are called radiographs.

- Form of Non-Destructive examination (NDE).

- Purpose is to inspect the quality of the weld or object under inspection without damaging the object.

- Industrial radiography requires penetrating X rays or Gamma rays.

Characteristics

Can radiation be seen?

Radiation itself cannot be seen, as it is not a physical object. However, some forms of radiation can produce visible effects. For example, when ionizing radiation interacts with matter, it can cause the emission of light, which can be seen as a flash of light or a glow. This effect is known as Cherenkov radiation and is commonly observed in nuclear reactors, particle accelerators, and some types of medical imaging equipment.

In addition, some forms of radiation, such as X-rays and gamma rays, can be used to produce images of the internal structure of objects, which can be seen by the human eye. These images are produced by the interaction of the radiation with the object being imaged, and are captured by a detector, such as a photographic film or a digital imaging system.

Can radiation be felt? Radiation itself cannot be felt, as it is not a physical object that can be touched or sensed by the human body.

Is radiation harmful? Radiation can be harmful to human health if exposure is not properly controlled. The potential harm from radiation depends on the type of radiation, the dose, and the duration of exposure.

Ionizing radiation, which has enough energy to ionize atoms and molecules, can be particularly harmful to human health. Exposure to high levels of ionizing radiation can cause damage to cells and DNA, which can result in radiation sickness, cancer, and other health problems. Long-term exposure to low levels of ionizing radiation may also increase the risk of cancer.

Can radiation be detected? Yes, radiation can be detected using specialized instruments that are designed to detect different types of radiation. These instruments can detect the presence and intensity of radiation, and can also identify the type of radiation, such as alpha particles, beta particles, gamma rays, or X-rays.

The most common types of instruments used for radiation detection include:

- Geiger counters: These instruments detect ionizing radiation by measuring the electrical charge produced when radiation interacts with a gas-filled chamber.

- Scintillation detectors: These instruments detect ionizing radiation by measuring the light produced when radiation interacts with a scintillating material.

- Dosimeters: These instruments measure the total amount of radiation that a person has been exposed to over a period of time and are commonly used to monitor radiation exposure in workers who are at risk of exposure to ionizing radiation.

- Spectrometers: These instruments measure the energy of individual radiation particles and can identify the specific type of radiation based on its energy signature.

Potential effects of radiation

Types of Industrial Radiography

X Ray

- Uses X-ray radiation source.

- The amount and intensity of radiation is controlled by the operator.

- Radiation is generated when machine is switched ‘ON’.

- Once you switch ‘OFF’ the electricity, no radiation is generated from the X-ray machine.

- Use of X-ray generators (other than accelerators) for industrial radiography up to 350 kVa does not require specific type approval.

- X-ray generators being a source of ionizing radiation require licensing by the Regulatory Authority,

Radio Isotopes:

An unstable substance/element that emits radioactive e.g. Ir 192.

Rem:

A measure of the dose of any ionizing radiation to the body tissue

Seivert (Sv):

Like the rem it is a unit of measure for the radiation dose equivalent to man.

1 Sv = 100 Rem

1 mSv = 100 mRem

Curie

The curie (symbol Ci) is a unit of radioactivity.

Gamma Ray

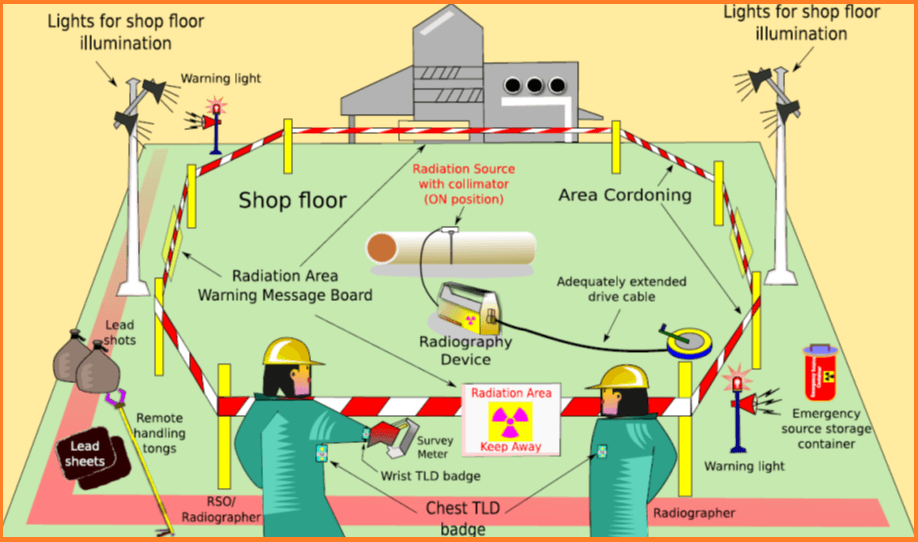

- Uses Gamma radiation source.

- Radioisotope is enclosed in a sealed container, called radiography cameras.

- Inside the gamma radiography camera, there are small radioactive sources in the form of pellets (typically of the size 0.3 mm x 2.5 mm dia.) that gives radiation.

- Radiation is emitted continuously from the source even when the camera is not operating.

- The outer thick shielding of camera protects the people from this radiation when camera is not operating.

- Only radioactive sources contained in approved Type B (U) radiographic projectors may be transported,

Gamma ray device

Exposure Device

Connecting remote cable to the exposure device

Exposure device locking ring/collar

Source guide tube

Collimator

Typical radioisotope used in Industrial Radiography

Decay Chart

- The activity (or strength) of the isotope can be found on the decay chart.

- Each isotope has its own individual decay chart.

- Decay chart gives the activity of the isotope on any given day.

- The reason it is called a decay chart is because the activity is not constant – each type of isotope has its own “Half Life”.

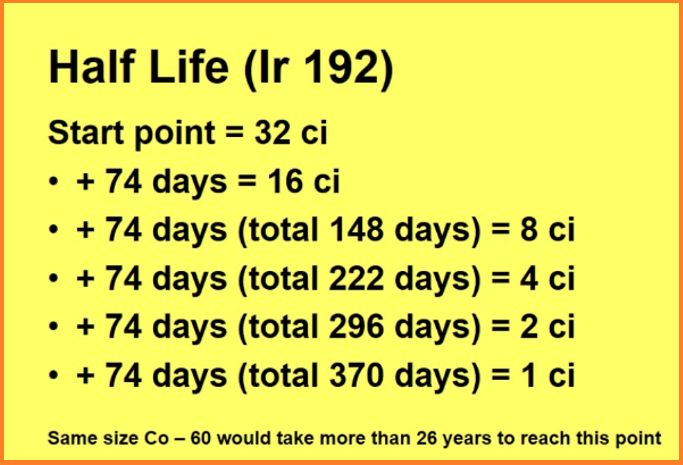

- Half life of Ir 192 is 74 days.

- This means that in 74 days time a 32 ci Ir 192 isotope decay to a level of 16 ci.

- What will it be in 148 days from today

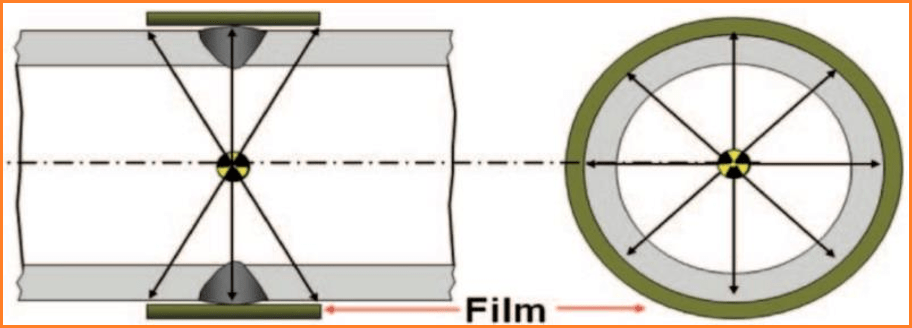

Single Wall Single Image (SWSI)

Double Wall Single Image (DWSI)

Methods of Protection

Basic protective measure used to minimize external dose include.

- Shielding

- Time

- Distance

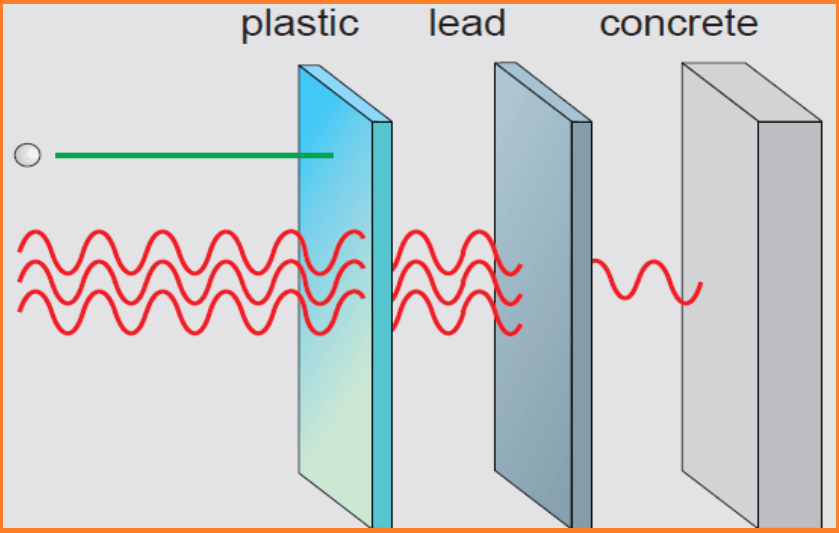

Shielding

- Gamma rays and X rays are more penetrating. However, as they cause ionization they may be removed from the beam or lose their energy. They thus become progressively less able to penetrate matter and are reduced in number, that is attenuated, until they cease.

- The half value thickness (HVT) or the half value layer (HVL) is that thickness of material which when placed in the path of the radiation will attenuate it to one half its original value.

- A tenth value thickness (TVT) similarly reduces the radiation to one tenth of its original value.

Time

- To reduce radiation doses, the time spent in radiation areas must be kept as short as possible. The longer the time spent in an area, the higher the dose received.

- In an area where the dose rate is 100 “Sv/h, the dose received will be.

Radiography test Safety distance

If the dose rate at 1 m from a source is 100 “Sv/h the dose rate at 2 m will be 25 “Sv/h.

Industrial Radiography Installations

Following requirements in respect of enclosed radiography shall be complied with:

- Fully enclosed and shielded, or enclosed on all sides with the exception of open top.

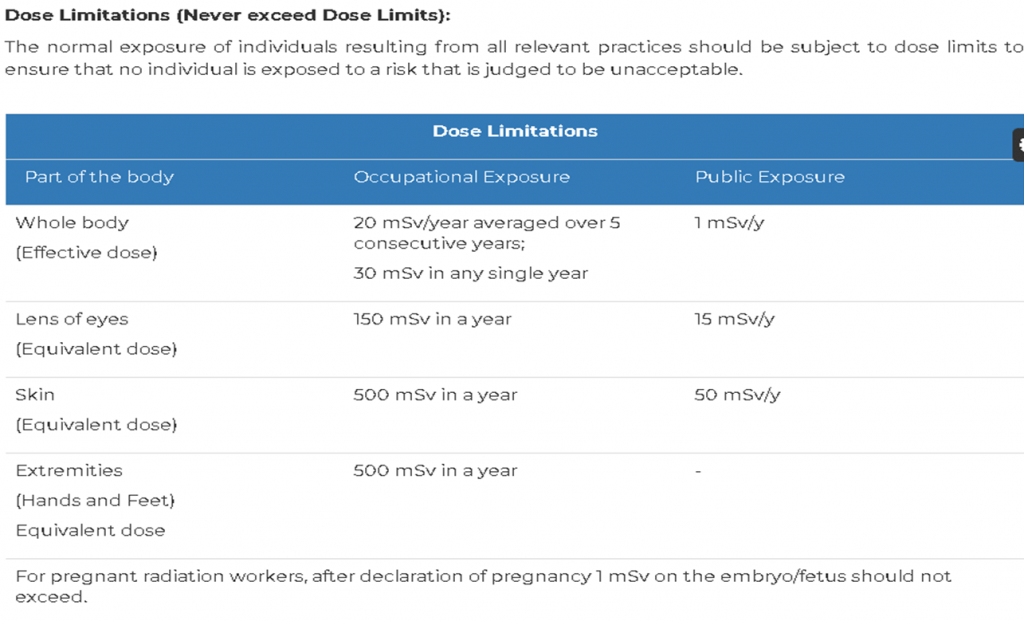

- Radiation levels outside the shielding do not exceed the annual dose limits for occupational workers and general public (1 mSv/Year)

- Controlled remotely.

- Provided with an electrical interlock so as to prevent operation of X-ray equipment or accelerator when the door is open or improperly closed.

- Exposure controls shall be located outside the exposure room.

- Placard indicating ‘RADIATION:RESTRICTED ENTRY’

- A logbook shall be maintained.

- Effective physical security shall be provided for the source(s) at all times.

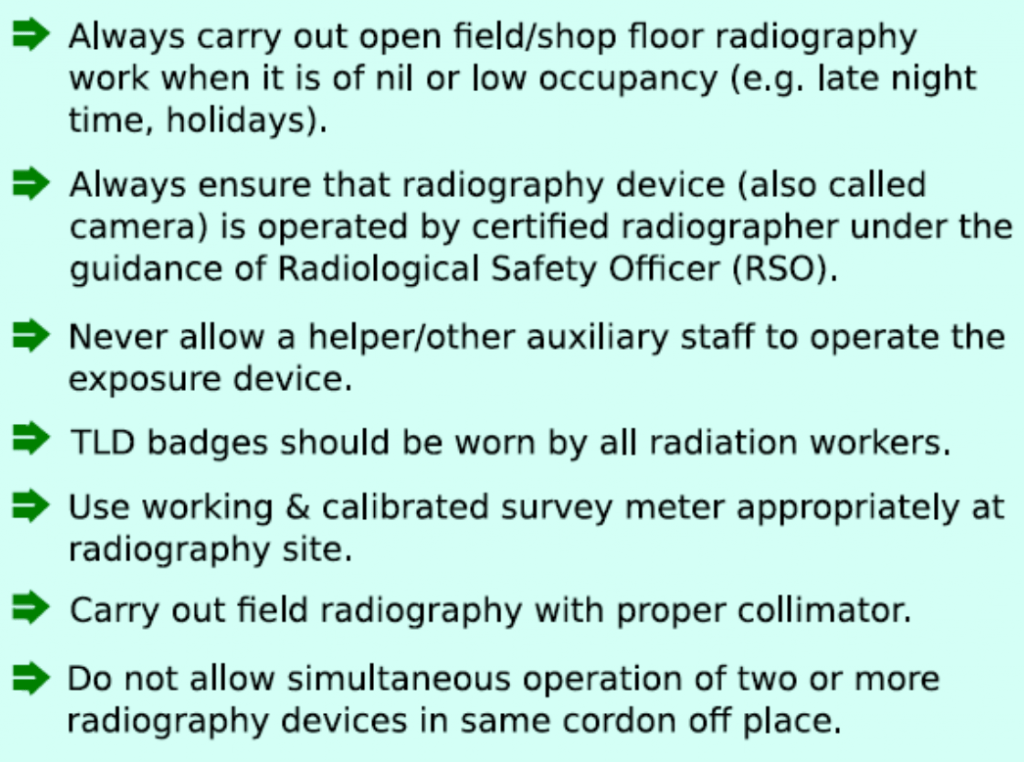

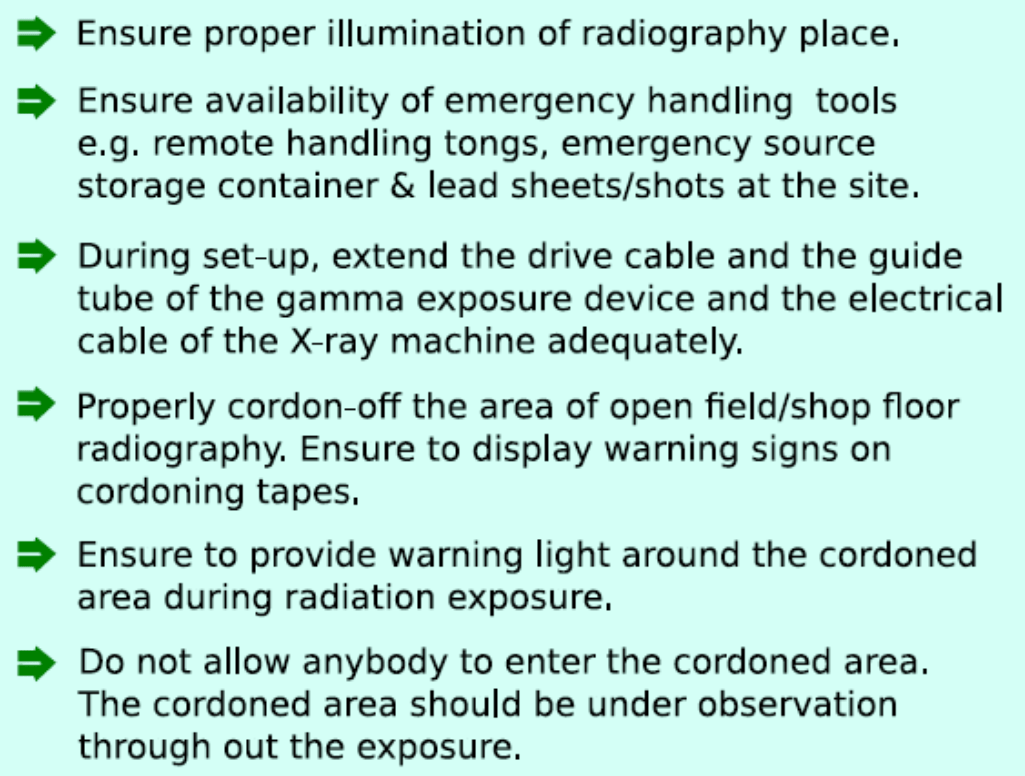

Following requirements in respect of field radiography shall be complied with:

- Carried out in locations where occupancy and traffic are as low as practicable.

- licensee shall obtain specific approval from the Competent Authority prior to movement of IREDs for undertaking open field radiography at any site.

- A well-defined a using warning signs and devices such as barriers shall be established using warning signs and devices such as barriers all around the site as appropriate.

- The radiation symbol and placards with the legend ‘RADIATION –KEEP AWAY’ and its equivalent in English / Hindi as well as in local language.

- Field radiography shall not be carried out without the use of an appropriate collimator except in case where it is not physically possible.

- Adequate distance shall be cordoned off around the radiation source and placards shall be displayed at the boundary.

- The boundaries of adjacent radiography sites shall not overlap.

- During radiography the drive cable and the guide tube of the gamma exposure device and the electric cable of the X-ray machine / portable accelerator shall be extended to the fullest extent possible.

- Once the radiography exposure commences, the radiographer shall move quickly to, and remain at, a location where the dose rate is as low as practicable.

- The cordon-off distance shall be determined on the basis of

- workload,

- Occupancy factor outside the boundary and

- Limitation of annual dose specified for public by the Competent Authority.

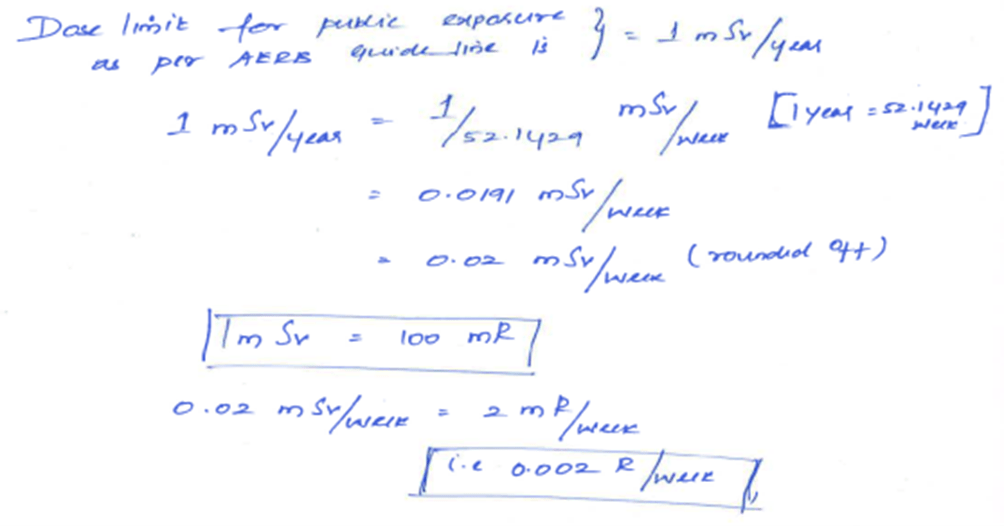

Exposure guidelines

How to calculate cordoned-off distance of Industrial Radiography

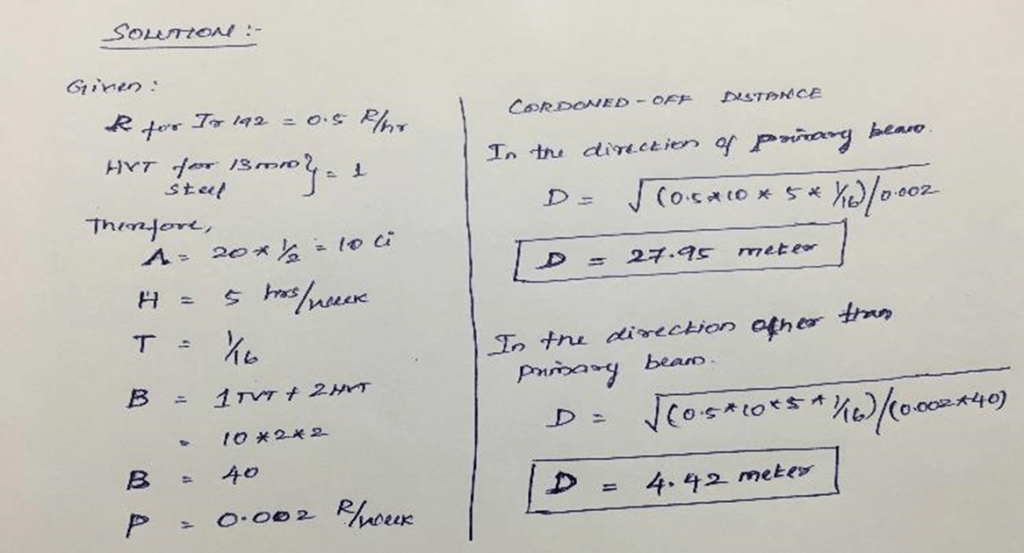

D (meter) = SQRT of [(R*A*H*T)/P] (Primary Beam)

D (meter) = SQRT of [(R*A*H*T)/(P*B)] (Secondary Beam)

Where,

R = RHM (R/Hr at 1m from 1Ci)

- R = 0.5 for Ir-192

- R = 1.3 for Co-60

- R = 0.203 for Se-75

•A =Source of strength in curie

•H =Workload in Hours/week

•T = Occupancy factor

- For full occupancy T=1 (Carrying out RT near plant/office/control room where peoples are always present or movement of peoples are always expected)

- For partial occupancy T=1/4 (Carrying out RT near plant/corridor/ stair case where movement of peoples are sometimes expected)

- For occasional T=1/16 (Carrying out RT in the plant/open space where movement of peoples are rare/ normally not expected)

•P = limitation of annual dose specified for public by the Competent Authority

•B = Shielding provided by the collimator (e.g. If collimator shields 1 HVT + 1TVT, B=20)

P = limitation of annual dose specified for public by the Competent Authority (1 mSv/year)

Radiographed objects do not retain any radiation and they do not become radio active. They are immediately safe to handle when the test is completed.

Radiation Monitoring Tools

TLD Badge BARC

Anticipated Problems

- More than 1 crew working

- Other persons working in the same area

- Unable to monitor the controlled area effectively

- People ignoring the warning signs and barrier tape.

Personnel Requirements

Radiological Safety Officer (RSO)

- Ensure compliance with the requirements specified in this AERB safety code Specific approval from the Competent Authority shall be obtained for being a RSO

- Carry out radiation surveys periodically, to ensure that safe radiography work procedures are being followed at the site(s)

- Ensure that personal radiation monitoring equipment, survey meters, source containers, shutters and source control mechanisms, X-ray equipment indicators and interlocks, door interlocks of enclosed radiation installation and area monitors, and other appropriate equipment related to radiation safety are inspected and tested/calibrated regularly

- No person receives radiation exposure in excess of the limits prescribed by the Competent Authority

- Direct reading dosimeters such as personnel dosimeters are issued, as necessary, used properly, collected and assessed

- Investigation of reported occupational exposure more than 10 mSv in a monitoring period is carried out and the investigation report submitted to the Competent Authority

- All radiographic equipment and emergency handling tools are periodically serviced and maintained in proper working condition.

Industrial Radiographer

- Training in radiography testing and safety (RT level-I or equivalent) or its equivalent recognized by the Competent Authority

- Do follow the procedures.

- Do use the appropriate equipment, including collimators.

- Do confirm that there are no other people working in the

- Area of radiography.

- Do use clear working signs and signals.

- Do set up the controlled area and the necessary barriers.

- Do confirm the location of the source, or that X rays are

- Not being generated, by use of a survey meter.

- Do secure and store the source or X ray machine when not in use.

- Do wear your personal dosimeter.

Emergency Response Planning

Accidents have occurred in industrial radiography resulting in workers and members of the public being exposed to radiation and other health and safety hazards.

Most likely events involving gamma exposure device.

- A source becomes stuck in the guide tube or the collimator, or near the entrance to the exposure device.

- Physical damage is caused that affects the shielding.

- A source becomes disconnected from its drive cable and remains in the guide tube.

- A source is projected out of the end of the guide tube.

- A pipeline crawler becomes stuck in a pipe with the source exposed.

- A source is lost.

- There is a fire.

- Unauthorized persons are present in the controlled area during an exposure.

Most likely events involving X ray exposure device

- An automatic exposure timer fails to terminate an exposure resulting in the tube

- Assembly remaining energized;

- The tube assembly is energized unintentionally;

- The operator neglects to terminate the exposure and fails to perform an adequate

- Tradition monitoring survey before manipulating the tube assembly;

- There is damaged, faulty or deliberately defeated safety equipment and systems

- Such as malfunctioning interlocks;

- Physical damage affects the shielding or filtration.

Emergency Response Resource

- Appropriate shielding (sufficient to attenuate the radiation significantly, for example, at least two bags of lead shot, i.e. 2 kg each for 192Ir and 10 kg each for 60Co);

- Tongs at least 1.5 m long, suitable for safely handling the source assembly;

- A shielded container;

- Appropriate hand tools;

- Radiation warning labels and signs;

- Plastic for preventing contamination of instruments;