Contents

Process control equipment

For temperature: Thermocouple, radiation pyrometer, optical pyrometers, resistance thermometer, all glass thermometers, electronic potentiometer, multi-point potentiometer, automatic electronic balanced bridge, ratio meter, automatic millimetres, Liquid type manometric temperature measuring instrument and direct acting temperature controller.

For pressure: Strain gauges, pressure transducer, pressure gauge, vacuum gauge, compound pressure and vacuum gauge, pressure head gauge, draft gauge, compound pressure and draft gauge, automatic pressure regulator, gas pressure regulator, fuel oil pressure regulator, direct acting recorders, diaphragm type breathing valve.

High Vacuum measurement: Bodurn gauge, bellos gauge, diaphragm gauge, mcleod gauge, Knudsen gauge, thermal conductivity gauge, rotating viscometer gauge, heat filament isolation gauge, Philips cold cathode ionization gauge.

For Level: Liquid level detector, float gauge, mercury manometer, aneroid manometer, liquid level measuring instrument, remote liquid level indicator with continuous type, fixed point indicating device, fluidised, solied level indicator.

For Flow: Liquid filled manometer, float type manometer, head flow meter, belt type meter, weight balance type meter, bellos meter, force balance meter, integrators, area flow meter, rota meters, position type area meter, positive displacement meter, mass and magnetic flow meter, densitometer, turbine velocity meter, volumetric flow meter, gasoline flow meter, gas flow controller, air flow controller, different pressure gauge for measuring flow rates.

Quality Analyser: Commercial automatic analyzer installed on process plant, chromatography apparatus, photoelectric calorimetric gas analyzer, gas/vapour monitor alarm devices and viscocimeter.

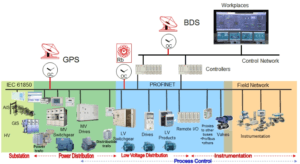

For centralize process control computers: Digital computer, autometric petroleum processing control system, automatic air operated centralizes monitoring and control system, electronic instrumentation system.

Revolution Meters: Tacho meter, Govemor, air velocity meter, acidometer.

Density & specific gravity meters: Psychomotor, hygrometer, dew point meters, viscometers, velocity measuring devices, consistent measuring devices, densitometer.

Process & control equipment characteristic: Chemical process and operation need efficient process and control system & a variety of instruments for them. Instrumentation and control has developed as a special branch of engineering.

Exclusive instrument control department and instrument control engineers are employed for this specific purpose.

Types of Instrument:

Manual, mechanical, pneumatic, hydraulic, electrical, electronics and computer aided, there quality and sophistication are day by day improving. There designing, erection and maintenance certainly need qualified and experienced person. When the safety, productivity and control system are governed by such instrumentation it occupied due importance and placing modern industries.

Process control systems can be classified, machine reactor or parameter wise, such as printing or painting machine control, turbine or compressed control, reactor or vessel control, pressure, temperature or flow control, speed control and instrument control. It can also be classified as manual control, auto control, semi-auto control, analogue control and computer control.

Classification also exists as mechanical control, pneumatic air control, hydraulic control, electronic control etc.

Main function (Objective of control system are two collect information are to measure and display it, To control and normal working and to detect fault and correct it. The control system depends on process characteristic.

Process characteristic as a mentioned by F.P lees include many thing as under:

1) Process characteristic which tend to make feedback control more difficult are measurement problem, dead time, recycle, very short and long time constants, nonlinearity, limit cycle, strong interactions, high sensitivity, high penalties and charges in parameters or constraint.

2) The process disturbance includes quality and availability of raw materials, products, services, plant equipment and environmental conditions. These disturbances may be due to malfunction of plant equipment or control system, process materials behaviour, drifting and decaying factors and links with other plants.

3) Function wise they required monitoring, optimization, scheduling, process investigation, plant commissioning, feed forward control etc.

4) Sequential control, characteristic include batch or continuous operation, plant start up or shut down, change in equipment, product quality or throughout, mechanical handling operations.

Control system characteristic include manual analogue and computer control.

Process control equipment

Manual control system includes instruments for whole range of chemical and physical properties and a wide range of display such as panel board displays, computer graphic and displays of flow, current measurement, alarms, sequential control, maloperations, commands etc.

Analogue control equipments are used for measurement, information and reduction and sequential control. They include data loggers, alarm sensors and trip systems. Trip system may be used for safety shut down function also.

Computer control includes direct digital control (DDC), programmable logic control, PLC, distribution control system (DCS) and supervisory control.

Present tend in control system is to increase degree of automation and change in operators role from process control to monitoring