After understanding the causation it is obviously essential to understand the principles of accident prevention and techniques of accident prevention. But before that, we will see the types of accidents first.

Contents

Types of Accidents:

Based on the severity of an injury, accidents are major, minor or near miss type. The combination of injury and property damage gives four types of the accident as follows:

- Injury and property damage (major).

- Injury and not property damage (major or minor).

- Property damage and not injury (minor or major).

- No property damage and no injury (near miss). Based on causation, they are of five types:

- Psychological causes – such as inexperience not motivated for safety, worry, emotional, wrong attitudes etc.

- Physiological causes – such as age, sex, body – build, poor hearing, vision, strength etc.

- Physical causes such as heavy workload, long working hours, no rest, unhealthy works environment, work at height, depth or in confined space, falling load etc.

- Mechanical, Electrical, Chemical, and Radiation causes – such as unguarded machinery, defective equipment, noise, vibration, obtruded pathway, sharp edge, electric shock, static electricity, chemical, poison, toxic gas, acid, fire, explosion, radiation etc.

- Environmental causes – weather effects, heat, cold, humidity, air, wind, rain, tide, lightening etc.

Causes of type No. 1 and 2 give rise to unsafe action while No.3 to 5 gives rise to unsafe conditions.

Fundamentals of Accident Prevention:

As explained by Heinrich, accident prevention is both, science and art. It represents control performance of man, machine and physical environment. The word ‘control’ includes prevention as well as the correction of unsafe conditions and actions.

Prevention is the first or initial part of ‘control’ which if practiced, subsequent control for consequence or effect may not be needed. Thus accident control is a vital factor in every industry, which if ignored or practiced unskillfully, leads to needless human suffering and business bankruptcy.

The accident-prevention task requires both, the short-term approach (direct control of personal performance and environment) and the long-term approach of instruction, training, and education. This task must be performed before an accident and injury occur. Subsequent efforts after accidents are also necessary.

Thus accident prevention may be defined as an integrated programmed a series of co-coordinated activities, direct to the control of unsafe acts and unsafe conditions and based on knowledge, attitude and the ability for the safety. It aims to serve industry, country, and humanity.

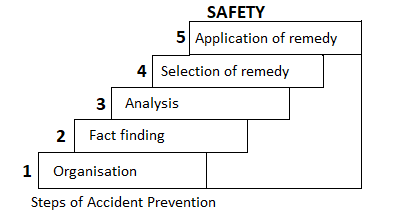

Five basic or fundamental steps for accident prevention (safe and efficient production) suggested by H.W Heinrich are:

- Organization.

- Fact-finding.

- Analysis of the facts found.

- Selection of remedy and

- Application of the remedy.

Sixth step ‘Monitoring’ (measurement of result, assessment i.e. comparison with legal criteria or standard, feedback, and further improvement) is also suggested. Such a review is necessary after all safety programs.

Also Read: HIRA

Organization:

The safety organization, management or at least the planned procedure, which it represents, is the vehicle, the mechanism by means of which interest is kept alive and the safety programs is designed, directed and controlled. The actual work of prevention is done by safety direction or manager, safety officer, and the line and staff supervisors with the active support of top management.

Safety is not only staff function but it is a line function also. Budgetary provision (cost allocation) for safety should be made from the very beginning.

Here organization does not mean safety department only. Safety is not a function of one department only. All the members of the organization (including all departments) have to contribute and play their role for safety.

The basic philosophy and safety policy for accident prevention and firm determination of the top management are utmost necessary.

Organization also includes the single person working for safety.

Also Read: FIRE MOCK DRILL REPORT

Fact Finding:

The knowledge of probable or potential hazards (facts) is derived from surveys, inspections, safety audits, observations, review or records, inquiry, investigation, and judgment.

Facts include past, present and future facts which have caused and which can cause accidents, past causes can be known by ‘accident records’ and inquiry. Future (hidden) causes can be known by HAZOP, HAZAN, safety audit, inspection etc.

The term hazard is synonymous with the phrase “direct and proximate accident cause” i.e. the unsafe personal act and/or unsafe physical, mechanical, electrical, chemical, environmental condition without which no accident can occur.

Personal hazards (unsafe acts) are violations of commonly accepted safety rules, practices, and procedures. Mechanical hazards (unsafe conditions) are of four groups: Static, kinetic, electrical and chemical (including radioactive or nuclear).

Also Read: JSA

Heinrich classifies the main causes of the accident as under:

The proximate cause is the nearest in ‘efficiency’ rather than whether it was closest in time or not. These are some general heads or categories under which more specific acts may be grouped. For example, the general head making safety devices inoperative can be sub-itemized as:

- Removing guards.

- Tampering with adjustment of guard including making interlock guard inoperative.

- Beating or cheating the guard.

- Failure to report defects etc.

Two types of main facts – unsafe acts and unsafe conditions – are discussed below.

Unsafe Acts:

The unsafe act is a human activity resulting in accident or injury to him, others, environment or all.

Also Read: PPE IS CODE

Some reasons for unsafe acts are as under:

- Improper Attitude – Willful disregard, recedes, lazy, disloyal, non-co-operative, fearful, oversensitive, egoist, jealous, impatient, absent-minded, excitable, obsession, phobia, inconsiderate, intolerant, mentally unsuited and other psychological reasons.

- Lack of knowledge or skill – Insufficiently informed or trained misunderstands, not convinced or need indecision, inexperienced etc.

- Physically Unsuited – Due to hearing, sight, age, sex, height, ill, allergic, slow reaction, intoxication, physically handicapped and other physiological reasons.

- Physical conditions – Space, light, ventilation, heat, layout or arrangement, material, tools, equipment, procedures, company policy, routing etc. make it awkward, difficult, inconvenient, embarrassing or impossible to follow safe practice rules.

The unsafe act should be noticed as early as possible and removed just after it is noticed. The purpose should be of removing injury, to prevent recurrence and not to punish any individual.

Workers should be properly observed for their unsafe act by seeing their selection and use of-

- The position of their standing and working.

- Tools and equipment including hand tools, power tools, lifting tools, PPE, FFE, etc.

- Method or procedure adopted by them.

- Traffic and driving rules.

Position and working should not be in dangerous conditions. Tools and equipment should be of the correct size and type, should be used correctly and in the right condition. Procedure or method should be safe and adequate. Where safety work permit is required, it must be explained and followed correctly. Driving should be safe or defensive and traffic rules must be followed. Drivers of vehicles of hazardous goods should have undergone specific training.

After seeing an unsafe act, observer’s (e.g. supervisor or safety officer) attitude should be to ‘talk with’ the worker and not to ‘talk to’ the worker. This means to call or advise the worker politely ask him why he is doing so or not using required tool, equipment, procedure etc, here his explanation, try to understand him and them explain him the ‘underlying hazard’ and make him convinced about ‘unsafe act’ and to correct it as per safety requirement.

Also Read: PPE

Some examples of unsafe acts and control measure are given below:

| Unsafe Action or Behavioristics Causes | Remedies | Responsibilities | |||

| 1. | Age, sex, experience | Proper selection of personnel | Personnel Dept. | ||

| 2. | Physical and physiological conditions such as work-load, physical strain, physical weakness, headache, cold, faintness, abnormal blood pressure, poor vision, handicapped, deaf, dumb, epilepsy etc. | A | Workload study and proper distribution | A | Supervisor, Safety Officer |

| B | Pre-employment medical exam | B | Physician, Factory Medical Officer | ||

| C | Periodic medical exam | C | Physician, Factory Medical Officer | ||

| D | Proper selection & placement of the person | D | Personnel Dept and Physician | ||

| 3. | Poor attitude and inability such as inattentive, insubordinate, un-cooperative, critical of supervision, bad skill or motives, wrong habits, intoxication, chance taking, absent-minded, disregard of safety rules & instruction etc. | A | Pre-employment psychological or ability tests | A | Personnel Dept and Psychologist |

| B | Proper supervision | B | Supervisor | ||

| C | Discipline | C | Supervisor and the Personnel Dept. | ||

| D | Personnel work | D | Personnel Dept. | ||

Unsafe Conditions:

Unsafe condition is created by an unsafe act of a person or act of God or by any agency or due to failure or weakening of any material, structure, situation, condition or system.

Observance of unsafe condition includes many areas such as proper lighting, ventilation, housekeeping, floors, platforms, handrails, toe guards, machine guards, tanks, vessels and pipelines, safety fittings and devices, electrical hazards, fire-prone condition, gaseous and dust exposures noise, vibration, heat or atomic radiation, loading, unloading and transportation etc.

Such unsafe conditions are due to non-provision, non-maintenance, poor maintenance, poor supervision, lack of training, improper design and layout of plant & machinery, poor lighting, poor ventilation, absence of guards and safety devices, failure of safety devices, equipment or tools, unsafe structure, poor housekeeping, fire-prone area, sources of ignition, static electricity, slippery floor, high noise, vibration, radiation etc.

Observation for unsafe working conditions should basic techniques of look, listen, smell and feel (LLSF) to detect the unusual condition of situation, position, noise, vibration, odor, temperature, pressure, out of control etc.

Also Read: FIRST AID

Some examples of unsafe conditions and control measure are given below:-

| Unsafe Conditions or Environmental Causes | Remedies | Responsibilities | |||

| 1. | Atmospheric conditions such as contents of air, temperature, humidity, ventilation, rain, lightning etc. | A | Air sampling, monitoring, cleaning, and conditioning. | A | Engineering and Utility Dept. |

| B | Humidity control. | B | Humidity or Engineering Dept. | ||

| C | Improve natural and artificial ventilation by the efficient exhaust system. | C | Engineering Dept. | ||

| 2. | Illumination, its distribution, and diffusion

-direct glare reflected glare, shadow, and color. | A | Improve natural and artificial illumination. | A | Lighting or Engg. Dept. |

| B | Good design and plant layout. | B | Plant Engineer | ||

| C | Proper color. | C | Color expert | ||

| 3. | Workspace, overcrowding. Obstructions etc. | A | Proper spacing area, height, machinery layout, headroom. | Plant Engineer, Civil Engineer | |

| B | Good design and housekeeping. | B | Plant Engineer, Supervisor | ||

| 4. | Bad housekeeping rubbish, disorder, unplanned layout. | A | Good housekeeping, orderliness, cleanliness, planned layout. | A | Design Engineer, Plant Engineer, Safety Officer, Purchase Dept. |

| 5. | Inherent properties and design defects of materials, machines, equipment, building etc. | A | Good design, good material, good construction & maintenance good procedures conforming to standards. | A | Design Engineer, Plant Engineer, Safety Officer, Purchase Dept. |

| 6. | Improper guarding like no-guard, inadequate guard, no maintenance etc. | A | Regular inspection | A | Supervisor, Safety Officer |

| B | Include guards in original design, order & contract. | B | Chief Engineer, Purchase Engineer, Safety Officer | ||

| C | Provide and maintain guards for existing hazards. | C | Supervisors | ||

| 7. | Defective materials, tools, equipment, vessels, stairs, pits, tanks, objects etc. | A | Regular inspection. | A | Supervisors |

| B | Preventive and corrective maintenance. | B | Maintenance Dept. | ||

| C | Good source of supply. | C | Purchase Dept. | ||

| 8. | Unsafe methods, procedures etc. resulting in an unsafe condition. | A | Job safety analysis, HIRAC. | A | Production or Plant Manager, Safety Officer |

| B | Job training. | B | Training Officer, Supervisors | ||

| C | Safety rules & procedures. | C | Dept. Head & Safety Officer | ||

| D | Inspection and correction. | D | Supervisor, Safety Officer | ||

| 9. | Rate of Production | A | Proper speed of work. | A | Production Manager |

| B | Time study, Motion study, job study, machine study etc. | B | Supervisor, Safety Officer | ||

| 10. | Noise & Vibration | A | Noise measurement & Control. | Plant Engineer | |

| B | Use of ear plugs, ear muffs etc. | Supervisor, Safety Officer | |||

| C | Vibration detection & controls. | Plant Engineer, Supervisors | |||

| 11. | Long working hours or excessive workload. | A | Supervision | A | Supervisors |

| B | Regulation of Law. | B | Personnel Dept | ||

| 12. | Insufficient or improper welfare facilities, clothing, PPE, etc. | A | Provide sufficient & good facilities for the toilet, urinals, washroom, lunch room, canteen etc. | A | Personnel Dept, Chief Executive |

| B | Provide safe clothing & PPE. | B | Personnel Dept., Supervisors. | ||

| 13. | Hazards in chemical industries, process, storage, transportation etc. | A | Detection of hazards by various techniques. | A | Supervisors, Safety Dept. Technical Dept. |

| B | Application of appropriate remedy such as safeguards & elimination of hazard level, lockouts, trips, alarms & interlocks, isolation, fail-safe design, failure minimization, failure rate reduction, screening, scrubbing, monitoring i.e. sensing, measuring, responding, and warning (audio-visual) of dangerous parameters, remote controls, microprocessors, records, auto controllers etc. | B | Chief Engineer, Plant Engineer, Production Engineer, Chemical Engineer, Supervisors, Safety Officers. | ||

| 14. | Emergency & Disaster | A | Onsite Emergency Plan. | A | Chief Executive, Safety Officer, Fire Officer, Emergency Staff. |

| B | Offsite Emergency Plan. | B | Government authorities. | ||

| 15. | The act of God and unexpected event | A | Assessment and safe planning. | A | Design Engineer, Top Management. |

| B | Onsite Emergency Plan. | B | Chief Executive, Safety Officer, Fire Officer, Emergency Staff. | ||

I am interested in having a copy of the NEW AMENDMENT LEGAL REGISTER

Sir can you sent the NEW AMENDMENT LEGAL REGISTER on my mail id- Lakhansinghsafety@gmail.com

Please

Good Safety site, all informative posts and quite useful, please post more such valuable Safety, Env, OH and Sustainability, Energy, Topics, it will help each one, industry, self and community.

OK SIR

Sir you only explains step 1 and Step 2 only. But where are the rest of other 3 steps.

Please explain it also.

Please share

Pls share accident investigation technique and sample report .

http://rlsdhamal.com/accident-investigation-analysis-and-reporting/

Sir how to prepare near miss report

Please tell me sir

http://rlsdhamal.com/nearmiss/