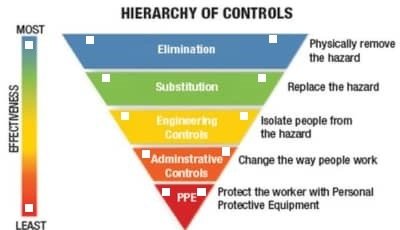

While doing the risk assessment, if risks are high then we need to introduce control measures to bring down the risk. In order to ensure that the risk assessor selected the best available option, the hierarchy of risk is created, wherein the topmost control measure in the list is the most preferred while the bottom-most is the least preferred.

These control measures are based on the principle of a safe place and a safe person. The top three in the list create a safe place, while the bottom two create a safe person and hence are less preferred.

Contents

The following is the general hierarchy of control:

- Elimination

- Substitution

- Engineering controls

- Administrative controls with warnings and signage

- Personal protective equipment.

1. Elimination: HIERARCHY OF CONTROL

The best and most preferred option is to eliminate the hazard. If a group of managers needs to travel from one city to the other to attend a meeting, the same can be done by using video conferencing, thus eliminating the hazard of traveling .robots can be deployed where are risks of manual handling and repeated movements of the limbs.

2. Substitution: HIERARCHY OF CONTROL

When hazards can’t be fully eliminated then the option of substitution needs to be tried. Substitution can be done in many ways. Following are some of the examples:

- Using a less-flammable liquid instead of a highly flammable one

- Using railways instead of road travel.

- Handling material using handling aids like trolleys instead of manual handling.

- Use of compressed air as a source of power instead of electricity

3. Engineering controls: HIERARCHY OF CONTROL

This creates engineered solutions to prevent exposure to hazards. The principle used here is to create a barrier between the worker and the hazards. There is various way to doing it.

- Isolation of total enclosure: in this, the hazard is isolation so that it cannot cause harm, like for example and the toxic chemical is handle in a fume cupboard thereby preventing its release into the atmosphere and hence the working on it or nearby need not wear breathing apparatus.

- Separation or segregation: it is placing the hazard in an inaccessible location. For example, the high voltage wires are placed overhead high enough to prevent anybody from reaching them. Separation or segregation could also mean having separate walkways for pedestrians and vehicles separated by hard barricading.

- Partial enclosure: in this, the hazard is partially enclosed for ease of operation. A wooden saw cutter would have a partial guard on it allowing the wood to be passed through for the cutting operation to be accomplished.

- Safety devices: this would include devices that are activated in the presence of certain hazards. For example, a fuse would break off the electrical supply in case of an overload current protecting the equipment and a subsequent fire hazard. Similarly, an RDC would trip off the supply if the fault current is detected.

4. Administrative controls with warnings and signage:

Hierarchy of control

These rely on procedures and behavior.

- Written procedures/ safe system of work: operating procedures or safe system of work is probably the most common form of control measure used in industry today and maybe the most economical and, in some cases, the only practical way of managing a particular risk. They should allow for the methodical execution of tasks. The development of safe operating procedures (SOP) should address the hazards that have been identified in the risk assessment (HIRA) process. If the risks involved in the task are high or medium, the detail of the system should be in writing and should be communicated to the employee formally in a training session. Details of the system for low-risk activities may be conveyed verbally. There must be records that the employee (or contractor) had training provided in the safe system of work and that they understand it and will abide by it.

- Reduce time of exposure: this involves reducing the time during the working day that the employee is exposed to the hazard, by giving the employee either other work or rest periods. It is normally only suitable for the control of health hazards associated with, for example, noise, vibration, excessive heat or cold, display screens, and hazardous substances.

- Information, instruction, and training: any operation of equipment or process needs to be done only by competent people. Competence can be achieved by adequate training and awareness created by providing them with information and instruction so that they are fully aware of the hazards in their workplace.

- Supervision: this is how management routinely keeps a check on the behavior of the workers. Supervision ensures that the workers are following the safe system of work and the controls are in place and been used appropriately. The level of supervision will depend upon the risk levels present.

CLICK HERE FOR? SOP FULL FORM

Safety signs

Safety and/or health sign: it is a type of sign which provides information about potential hazards, emergency exits, and fire protection equipment in the work environment. The information can be conveyed by means of

- Signboard

- Colour

- Illuminated sign

- Acoustic signal

- Verbal communication

- Hand signage

Signboard:

it is a type of board that provides information of instruction by the combination of shape, color, and a symbol.

These boards not only consist of written text but also consist of pictograms to overcome the language barrier.

Following are the type of signboards:

Prohibition: round in shape, red edging with the diagonal crossbar on a white background, the symbol within the circle to be black denoting a safety sign that indicates that certain behavior is prohibited. The red part shall be 35%.

Warning: the triangle shapes with a black border and symbol within the yellow area denoting a safety sign that gives a warning of a hazard. The yellow part shall be 50%.

Mandatory: round in shape, the white pictogram on blue background and blue shall be 50%.

Safe condition: oblong or square in shape with a white pictogram on green background and green shall be 50%.

Fire equipment: a red oblong or square with a pictogram on a red background denoting a safety sign that indicated the location of fire-fighting equipment.

The red portion shall be 50% here as during the emergency, the power failure will be there and hence this shall be visible in emergency lighting.

Safety color: color is defined with a specific meaning with respect to safety (e.g. yellow means ‘be careful’ or ‘take precaution’).

Symbol or pictogram: it is used on a signboard or illuminated sign to overcome the language barrier (e.g. the trefoil ionizing radiation warning sign).

Illuminated sign: a sign made of transparent or translucent material which is illuminated from the inside or the rear to give the appearance of a luminous surface (e.g. emergency exit sign).

Acoustic signal: a sound signal which is transmitted without any manual interventions (e.g. a fire alarm).

Verbal communication: communication of a predetermined spoken message by a human or artificial voice.

Hand signal: it provided an easy means of communication with movement or position of the arm or hands and helps to execute maneuvers operation with ease.

Sign for marking obstacles and dangerous locations

Red and white stripes indicate entry with permission only. Black and yellow stripes indicate entry can be without permission, but with precautions taken.

CLICK HERE FOR 👉 HIRA AND JSA

5. Personal protective equipment (PPE):

FAQ: Hierarchy of Control in Safety

1. What is the Hierarchy of Control in safety?

The Hierarchy of Control is a systematic approach to managing and controlling workplace hazards. It provides a prioritized list of strategies to eliminate or minimize risks, starting with the most effective measures.

2. What are the different levels in the Hierarchy of Control?

The typical hierarchy includes five levels: a. Elimination b. Substitution c. Engineering Controls d. Administrative Controls e. Personal Protective Equipment (PPE)

3. What is “Elimination” in the Hierarchy of Control?

Elimination involves completely removing the hazard from the workplace. This is the most effective control measure as it eradicates the risk altogether.

4. What is “Substitution” in the Hierarchy of Control?

Substitution involves replacing the hazard with something less hazardous. This could include using safer materials or processes.

5. Explain “Engineering Controls.”

Engineering Controls focus on designing the workplace to reduce or eliminate exposure to hazards. Examples include installing barriers, ventilation systems, or safety interlocks.

6. What are “Administrative Controls”?

Administrative Controls involve implementing changes in work practices and policies to reduce the risk. This may include training programs, job rotation, or changing work schedules.

7. What role does “Personal Protective Equipment (PPE)” play in the Hierarchy of Control?

PPE is the last resort in the Hierarchy of Control. It includes equipment like gloves, goggles, helmets, etc., to protect workers when other control measures are not feasible.

8. Why is the Hierarchy of Control important?

It provides a structured approach to risk management, ensuring that the most effective measures are considered and implemented first. This helps in creating a safer work environment.

9. How can the Hierarchy of Control be applied in different industries?

The Hierarchy of Control is a flexible framework that can be applied to various industries by tailoring control measures to specific hazards and work environments.

10. Are there any limitations to the Hierarchy of Control?

While effective, it’s essential to recognize that not all hazards can be eliminated. The Hierarchy serves as a guideline, and a combination of control measures may be necessary for comprehensive risk management. Regular review and reassessment are also crucial as workplaces evolve.

11. How can employees be involved in the implementation of the Hierarchy of Control?

Employees should be actively involved in hazard identification, reporting, and suggesting control measures. Training programs can help raise awareness about the Hierarchy of Control and its application in daily work practices.

12. Does the Hierarchy of Control only apply to physical hazards?

No, the Hierarchy of Control is applicable to various types of hazards, including physical, chemical, biological, ergonomic, and psychosocial hazards. It provides a universal framework for managing risks in diverse work settings.

Also, read this: –

These should be considered as a last resort only when the other control measures are not practically feasible or they are not fully controlling the risks. They generally create a second life of defense. There is various type of PPE.

- Helmet for protecting the head against falling objects.

- Goggles and visors for protecting the eyes against flying objects of fume.

- Hand gloves to protect the skin against absorbing dangerous chemicals.

- Ear defenders to protect against loud noise.

- Respiratory protection devices to protect against dust, vapor, and fumes that could be inhaled.

Following are the benefits of PPE:

- It gives immediate protection to allow a job to continue while engineering controls are put in place;

- In an emergency it can be the only practicable way of effect the in rescue or shutting the own plant in the hazardous atmosphere;

- It can be used to carry out work in confined spaces where alternatives are impracticable. But it should never be used to allow people to work in dangerous atmospheres, which are, for example, enriched with oxygen or potentially explosive.

Following are the limitations of PPE:

- Only protects the person wearing the equipment, not others nearby.

- Relies on people wearing the equipment at all times.

- Must be used properly.

- Must be replaced when it no longer offers the correct level of protection. This last point is particularly relevant when respiratory protection is used.

- It may increase the overall risk by impairing the senses, for example, goggles may mist thereby causing impaired vision.

- They may be incompatible thereby reducing its protection. For example, eye protection may interfere with the earmuffs.

- If it fails, it fails to danger and the mat often gets contaminated if not stored correctly.

- It is expensive in the long run.

You are reading at rlshumancare.com. Do not forget the name RLS HUMAN CARE. Please share with your friends and help RLS HUMAN CARE. Thank You!!

The nice and very specific information on the subject content.

I understand this is the better way of influencing the world safety culture to come in front to every one view.

please be in loop of this kind coaching and finding.

It’s a very useful for avoid the accident & we will progres the target of zero accident. This type tools vvery useful to safety officer during JSA. In our organisation.

Thanks.

Please sir send me file

EXCELLENT INFORMATION.

PLEASE SEND ME CONSISTENT CIRCULATION.

THANK YOU.

JONATHAN DOCTOR FLORES

FHSE Incharge

JGC Gulf International Co. Ltd.

Kingdom of Bahrain