CNC Machine (Numerical Control of machine tool) means the automatic control of its operation under a program expressed in numbers or symbols which determine values and kinds of displacement of operative members of the machine, Such machine tools are known as NC machine tools. Which their control is computerized, they are known as Computerized Numerical Control (CNC) machine tools.

The change-over from job to job in CNC Machine takes less time than other types of automatic machines where this is done by changing cams or templates, displacing stops, limit switches, etc. Such automatic machines are also program-controlled, but their set up is complicated. They are advantageous only in mass and batch production.

The main feature and advantage of the CNC Machine tool is the simplicity of changing over, which makes it possible to develop an economically effective system of automation for small-batch and single-piece production.

The program can be fed directly in the machine for limited volume or it can be prepared outside the machine for an unlimited volume. In the second method, information is stored in the storage medium like punched tapes, magnetic tapes, wire discs, or drums, paper tapes, punched cards, films, and in the movement of the storage medium, this information is successively readout and is employed to control the movements of the machine operative members.

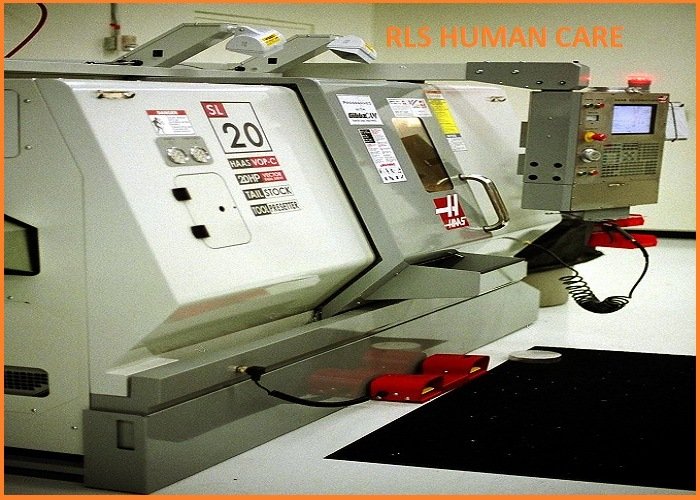

The storage medium is usually prepared outside the machine by applying computing technology (computers) and special devices for recording the program. CNC system can be employed for lathes, milling machines, drilling, boring and other machines with automatic tool changers which make it possible to increase output, reduce reject and inspection operations.

The decimal system or binary system of noting numbers is used to represent the machine part movement. The displacements are specified in pulse systems with the number of pulses coded. The information can be recorded for instance in the form of holes on a punched tape. In the computer system, electronic media is used to give the number, code, symbol and graphic to store and translate information for automatic mechanical movement.

Contents

The Basic Components of CNC Machine

- CNC (Computer numerical control), It contains are:

- CPU (Central processing unit)

- PLC (Programmable logic control)

- Inputs/outputs

- Memory

- Axis and spindle control, It contains are:

- Servomotor for axis

- Power motor for spindle

- Feedback for drivers

- Positioning display system, It contains are:

- Position sensors

- Processing of sensors

- Display unit

The function of the CNC machine is to take the commands in the form of a program or by manual data entry and to give the command to the motors to achieve the required position movement. It also stores the programs, controls the logic functions of the machine and checks all inputs/outputs. To take care of the function it has the following components.

Safety & Maintenance of CNC Machine

Many tools are fitted in an auto tool manager which operates suddenly as per the program. Therefore all moving mechanisms of a CNC machine should be totally enclosed in a plastic cover to afford safety and visibility. Such covers should be so interlocked that inner parts will not start till the cover is closed and will not open till the inner parts are stopped.

Limited openings for job insertion, machine part ejection, and scrap removal are permitted. Any manual control, if required should be remote. CNC machines should not start inadvertently.

Necessary trips and locks are provided for built-in safety. Electrical double earthing, start-stop switch in easy reach, sound foundation to eliminate vibration, automatic lubrication system, mono-rail, and chain pully block to handle heavy machine parts or the job, numerical display system, sufficient surrounding space for work and maintenance and protection of computer system are basic safety requirements.

Tool magazine operating at a height as in case of steel plant is considered safe by position. CNC machine operators should be qualified and well trained for the operation of the machine and the job.

Selection and Care of Cutting Tools

Safe Operations of CNC Machine

Top 75 Health and Safety Blogs and Websites on the Web

Also, read this:

Safety in gas cutting and welding

People also search for:

- CNC machine definition

- CNC machine working

- CNC machine working principle

- CNC machine safety

Wow nice good job

Thank You!!

Good information ??

Very good information.

Thank you sir