Contents

Back fire –

The momentary recession of the flame in to the torch tip followed by immediate reappearance or complete extinguishments of the flame.

Flash Back –

A recession of the flame in to or back of the mixing chamber of the torch.

Braze welding –

A method of welding where by a groove, fillet, plug, or slot weld is made using a nonferrous filler metal, having a metal point hallow that of the base metal but above 800 degree F.

Cover glass –

A clear glass used in a goggles, hand shield and welders screen to protect the filter glass from the spatters.

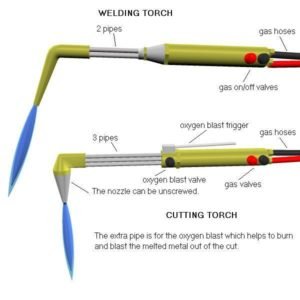

Gas cutting torch –

This is a device used in gas cutting for controlling the gasses used for preheating and the oxygen for cutting the metal.

Metal arc welding electrode –

This is the filter metal in the form of the wire or the rod, either bare or covered through which current is conducted between the electrode holder & the arc.

Flash back arrester –

It is the device used to arrest (stop) the recession of the flame in to back of the mixing chamber of the torch.

Stud welding –

An arc welding where in coalescence is produced by heating with an electric arc drawn between a metal stud, and similar part, and the other work part until the surface to be joined are properly heated, when they are brought together under pressure and, no shielding is used.

Gas cutting –

The process of cutting ferrous metal by means of the chemical reaction of oxygen on elements in the base metal.

Manifold –

A multiple header for connecting several cylinders to one more torch supply lines.

Mixing chamber –

That part of a welding or cutting torch where in the gases are mixed for combustion

Tack weld –

A weld made to hold parts of the weldment in proper alignment until the final welds are made.

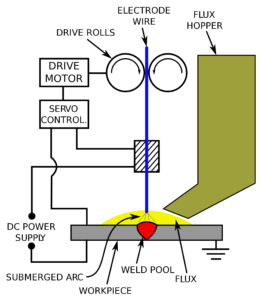

Submerged arc welding –

An arc welding process where in coalescence is produced. By heating with an electric arc between a bare metal electrode and the work, the welding is shielded by a blanket of general, fusible material on the work. Pressure is not used and filler metal is obtained from the electrode.

Welding rod –

Filler metal, in wire or rod form, used in gas welding and brazing process, and those arc-welding process where in the electrode does not furnish the filler metal.

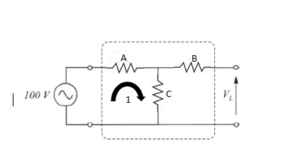

Open-circuit voltage –

In arc welding, the voltage between the terminals of a power source when no current is flowing in the circuit.

Electrode holder –

A device used for mechanically holding the electrode & conducting current to it.

This is the great piece of information, Thank you so much for sharing the tips are really helpful.