Contents

The objective of the Hazard Identification Risk Assessment (HIRA)

Objective of HIRA: The objective of the Hazard Identification Risk Assessment (HIRA) is to identify and assessing the hazard associated during the construction of the project and thereby controlling the risk by implementing mitigation measures before the start of the work to avoid the incident. HIRA helps to become proactive rather than just reactive.

HIRA, which stands for Hazard Identification Risk Assessment, is an essential process in ensuring safety in various industries. It involves identifying potential hazards and assessing the associated risks in order to implement necessary measures to control and mitigate these risks. HIRA helps organizations become proactive in preventing accidents and incidents rather than just reacting to them. By conducting a thorough HIRA create a safer working environment for workers.

During the HIRA process, hazards are identified and assessed based on their potential consequences, probability of occurrence, and existing control measures. The risks associated with the hazards are then evaluated using methods such as Risk Assessment Matrix (RAM). This enables organizations to prioritize and determine which risks require immediate attention and which can be managed with existing controls.

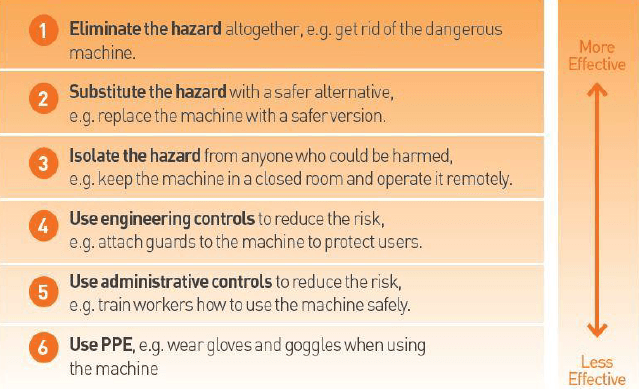

Controls are categorized based on the hierarchy of controls, which includes eliminating the hazard, substituting it with a safer alternative, isolating it, engineering controls, administrative controls, and the use of personal protective equipment (PPE). The effectiveness of these controls is regularly evaluated to ensure they are reducing the risk to an acceptable level.

It is important to regularly review and update the HIRA to account for any changes in the work environment, regulations, or incidents that may occur. By doing so, organizations can continuously improve their safety measures and minimize the occurrence of accidents.

Overall, conducting a thorough HIRA helps organizations identify, assess, and control hazards and associated risks to create a safer working environment for everyone involved.

CLICK HERE FOR 👉 JSA

The following terms used in HIRA

ALARP: As Low as Reasonably Practicable. This is the level, where the time, effort, difficulty, and cost of further reduction measures becomes disproportionate to the additional risk reduction from the incremental effects.

CONSEQUENCE: The unmitigated impact of the hazard in terms of People, Environment, Asset, and Reputation.

WHAT IS HAZARD?

Hazard is a potential condition awaiting to be converted into an accident if proper precautions are not taken into consideration. Hazard is the mother of the accident.

HIERARCHY OF CONTROLS: Order of preference in the application of risk mitigations. The order is: Eliminate, Substitute, Isolate, Engineer, Administration, and PPE.

PROBABILITY: The possibility of the event happening.

WHAT IS RISK?

The chances of a hazard actually causing an injury or disease. MAJOR RISK: A risk that has the potential to result in a Major Accident classified as high risk to people, assets, the environment and/or company reputation as defined in TPL SHE Risk Matrix.

CLICK HERE FOR 👉 ENVIRONMENT MANAGEMENT PLAN FOR CONSTRUCTION SITE

The acronyms used in HIRA have the meaning defined below:

| E&I | Electrical and Instrumentation |

| HIRA | Hazard Identification Risk Assessment |

| SHE | Safety, Health, and Environment |

| HRA | Health Risk Assessment |

| RAM | Risk Assessment Matrix |

| OCP | Operational Control Procedure |

| HIRAC | Hazard Identification Risk Assessment and Control |

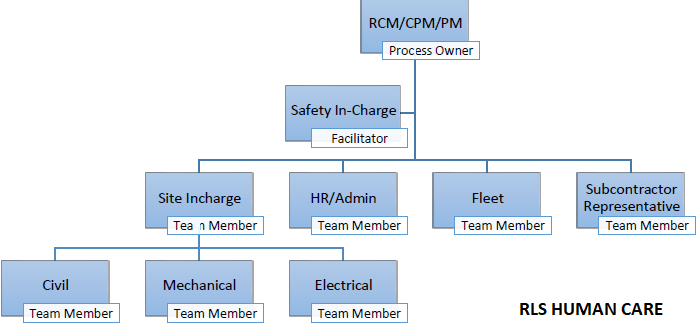

HIRA ORGANISATION STRUCTURE FOR CONSTRUCTION SITE

RESPONSIBILITIES OF HIRA TEAM

| S. No. | Person | Responsibility |

| 1. | RCM/CPM/PM | 1. RCM is a process owner. 2. To form a HIRA Cross-functional team along with Site In-charge/Engineer (Civil, Electrical, Mechanical), Safety In-charge, Fleet, HR/Admin, and subcontractor representative. 3. Any material to be required as per the Precautionary measures and proposed control measures need to arrange 4. To review the updated HIRA and approve it. |

| 2. | Site In-charge | 1. To prepare the Method statement of each activity. 2. To participate in preparing HIRA. 3. To incorporate all the Hazard & appropriated precautionary measures as per the site environment, to bring down the risk level to the acceptable risk and communicate down the level. 4. Before issuing PTW ensure all precautionary measures are in place. 5. Ensure HIRA talk by site supervisor before starting the activity. |

| 3. | Safety In-charge | 1. Work as Facilitator to prepare HIRA based on the method statement. 2. Ensure all concerned person is available for preparing HIRA. 3. To incorporate all the Hazard & appropriated precautionary measures in HIRA format along with responsibility. 4. Communicate updated HIRA to all concern for implementation and ensure all precautionary measures are in place. The same shall be communicated to SBG SHE Head and Corporate SHE Team. 5. To ensure safety supervisor shall monitor for any deviation. 6. If any deviation, escalate to Site In-charge, RCM/CPM/PM, and SHE Head. |

| 4. | Sub-contractor Representative | Follow the precautionary measure as per the HIRA |

FREQUENCY OF HIRA FOR CONSTRUCTION SITE

- The site Team needs to prepare Dynamic HIRA along with the proposed control measure on the basis of Master HIRA.

- HIRA needs to be prepared before the start of each activity.

- HIRA needs to be updated after the occurrence of any incident, management of change, change of work methodology, and change of any regulation. If there is no change then it should be reviewed half-yearly.

METHODOLOGY OF HIRA

The HIRA review is the structured multidisciplinary hazard identification, risk assessment, and methodology that provides a detailed review of hazard, risk, and control of the construction activities. The review is facilitated by the relevant construction personnel in the brainstorming session.

CLICK HERE FOR 👉 HIRA vs JSA

Overview of HIRA Methodology

HIRA Flowchart

Steps of HIRA review is summarized as follows:

- Classify work/assessment units or work activities during the construction phase (based on Work Method Statement).

- Identify the hazards associated with work activities.

- List the Consequence of the hazard involved in the activity.

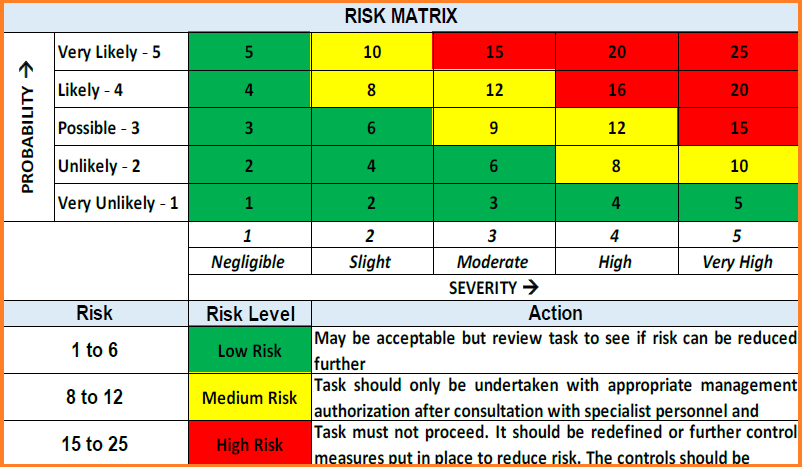

- Assess and score the risk (i.e. probability X severity) using the Risk Matrix as per TPL Risk Assessment Matrix (RAM).

- List out present controls (preventive and recovery).

- Assess the risk based on present controls.

- Reassess the medium and high risk to bring it down to acceptable risk.

- Verify compliance to regional Regulation, Project Specifications, and applicable international codes and standards.

RISK ASSESSMENT MATRIX

For each of the identified hazards, the level of risk is assessed based on the TPL SHE Risk Assessment Matrix during the HIRA review. Risk ranking is firstly performed based on the unmitigated risk for each hazard, and then the level of risk is re-evaluated after taking into consideration of the existing prevention/mitigation measures and controls.

If the risk is in the Green region on the TPL SHE RAM, this is broadly acceptable and no further action is required. If the risk is in the Yellow region on the TPL SHE RAM, this is in the tolerable regions and needs to be demonstrated to be As Low As Reasonably Achievable (ALARP) by recommending further action.

If the Risk is still in the Red region, this is not acceptable and action definitely needs to be taken. HIRA Review team shall discuss the proposed actions, where applicable, to address the hazard that is ascribed with a medium to high-risk rating.

CONTROL MEASURES

Controls are required to be separated into preventive and recovery. Controls are required to be categorized using the hierarchy of controls (eliminate, substitute, isolate, engineering, administrative, and PPE). This allows the review of controls to ensure the principle of inherently safer construction is being applied.

EFFECTIVENESS

- Present Risk reduced to Acceptable Risk

- Reduction of incident

- Reduction in repetitive observation

- Improvement in Behavioural Safety

FAQs about Hazard Identification Risk Assessment (HIRA) in Safety:

1. What is HIRA?

HIRA stands for Hazard Identification Risk Assessment. It is a process used to identify potential hazards and assess associated risks in order to implement necessary control measures in various industries.

2. Why is HIRA important?

HIRA is important because it helps organizations become proactive in preventing accidents and incidents rather than just reacting to them. It allows them to identify, assess, and control hazards and associated risks to create a safer working environment for their employees.

3. What is the objective of HIRA?

The objective of HIRA is to identify and assess hazards associated with a project or work activity, and to control the risks by implementing mitigation measures before the work starts. The aim is to avoid incidents and create a safer work environment.

4. What is the methodology of HIRA?

The methodology of HIRA involves a structured multidisciplinary approach to hazard identification, risk assessment, and control of construction activities. It includes steps such as classifying work activities, identifying hazards, assessing and scoring risks, listing control measures, reassessing risks, and ensuring compliance with regulations.

5. How often should HIRA be conducted?

HIRA should be conducted before the start of each activity, and it should be updated after any incidents, changes in work methodology, or changes in regulations. If there are no changes, it should be reviewed at least every six months.

6. What is the Risk Assessment Matrix (RAM)?

The Risk Assessment Matrix is a tool used to assess the level of risk associated with identified hazards during the HIRA process. It combines the factors of probability and severity to determine the overall risk level and prioritize control measures.

7. What are control measures?

Control measures are actions or measures taken to prevent or mitigate identified hazards and reduce associated risks. They can include eliminating the hazard, substituting it with a safer alternative, isolating it, using engineering controls, administrative controls, or personal protective equipment (PPE).

8. What is ALARP?

ALARP stands for ‘As Low As Reasonably Practicable.’ It is a level of risk where the time, effort, difficulty, and cost of further reduction measures become disproportionate to the additional risk reduction gained.

9. How can HIRA be effective?

HIRA can be effective by reducing the identified risks to an acceptable level, reducing incidents and repetitive observations, and improving behavioral safety. Regular evaluation and improvement of control measures also contribute to the effectiveness of HIRA.

10. Where can I download HIRA templates?

You can download HIRA templates in PDF or Word format from reputable safety websites or consult with safety professionals. Ensure that you customize the templates to suit your specific industry and work activities.

Remember that the successful implementation of HIRA requires commitment, collaboration, and regular review to ensure a safe working environment for all.

in which Act and rule mention about accident or incident investigation committee?

Thanks sir for giving us a valuable & very needful updated knowledge

Every Data is useful.

Thank you sir.im

I am student of hse field. I want to study.

It’s very helpful

Thanks ! for this nice elaboration on the Topic.

Thank you sir for enhancing our knowledge..