Checkpoints for Routine Inspection of a Chemical Factory

Checkpoints for Structural Stability and Safety:

- Parts of building/shed requiring repairs.

- Parts of vessels/machinery requiring repairs.

- Parts of Stairs/platforms requiring repairs.

- Parts of storage/overhead tanks requiring repairs.

- Parts of pit, sump, and gutter cover requiring repairs.

- Others requiring repairs:

- Lightening arrester required? Provided?

- New extension/alteration.

- Stability Certificate available?

- Specific remarks, if any (Doors open outwards? etc.)

Checkpoints for Solvent/Liquid chemical Storage Tanks:

- Vents with flame arrester.

- Flare connection.

- Automatic level indicator and high level alarm.

- Absorption media connection with drain safety valve.

- Flame/smoke detector with alarm.

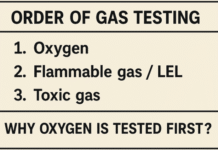

- Toxic/Combustible explosive gas detector with alarm.

- Bund wall/dike/sump.

- Remote control device for emergency drain and water spraying.

Checkpoints for Gas Cylinders Storage:

- Name & No. Of cylinders usually stored.

- Colour code of cylinder ensured.

- Is the storage separate, away from source of heat and cordoned?

- Gas detector with alarm.

- FFE & PPE nearby?

- Are the cylinders safety arranged?

- Notice of operating/handling instructions.

- Fire extinguishers.

Checkpoints for Chemicals Store/Godowns:

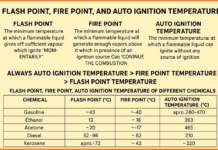

- Combustible chemicals separate?

- Reactive (oxidising, reducing, compatible, dissolving, flammable, explosive, corrosive etc.) chemicals separate?

- Inorganic & Organic, liquid (drums, carboys etc.) separate?

- Poisonous chemicals in a locked room?

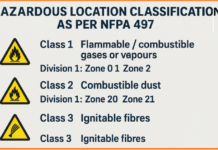

- Flameproof fitting necessary? Provided?

- Earthing, FFE & PPE, Cautionary notice provided?

- All doors and windows can be locked properly?

- Ventilators as per vapour density provided?

- For acid/alkali, safety shower near?

- Quantity of each raw material and each product stored at any time.

Checkpoints for Pressure Reactions:

- Safety valve

- Pressure gauge

- Temperature gauge

- Second safety valve necessary? (above 100 psi)

- Steam pressure reducing valve necessary?

- Rupture disc necessary?

- Drowning tank necessary? (after S.V/R.D)

- Scrubber necessary?

- Stirrer stop-alarm necessary?

- Flame-proof motors/fitting necessary?

- Earthing necessary?

- Temperature cut off device necessary?

- Feed/charge control necessary?

- Quenching device for neutralisation necessary?

- Drain/Discharge pipe?

- Manhole

- Vessel structure, foundation, position safe?

- Pressure Test Report available? Date of last testing

- Surrounding space open?

- Documents of complete reaction, reaction rates, pressure/temperature rise, exothermocity etc. Available?

- Sources of ignition near? Safety measures.

- Platforms, stairs, fencing, guarding provided?

- Gas/Flame detector in vicinity required?

- If jacketed (limpet coil) vessels, fitting with the jacket and how is the heating/cooling system?

- Other device necessary (pressure temperature recorder, auto controls, alarms, remote controls etc.)

Checkpoints for Distillation Process:

- Nature and type of heat source (direct heat, heat through jacket, heating media etc.)

- Heat control devices provided?

- Temperature gauge

- Drain pipe

- Stirrer necessary

- Flameproof motors, fitting necessary?

- Platform, stairs, railing, guarding provided?

- Gas/Flame detector in vicinity required? Provided?

- Pressure/Vacuum gauge

- Manhole

- Source of spark away?

- Other necessary and provided?

Checkpoints for water Facility:

- Water showers at 2.1 mtr height with 2.5 cm dia pipe provided? Where not provided? Water blanketing necessary?

- Eye washers/Bottle/Wash basins/Taps

- Bathrooms provided?

- Cooling water in jackets, condenser etc. Available for all hours? Own overhead water tank available? If not, what is the alternate arrangement?

- G. Set or Diesel engines ready to run water pumps when electricity fails?

- Drinking water facility available?

Checkpoints for Emergency Action Plan, Safety Manual, Workers Training etc.:

- Planned for operating emergency? (small fire, air failure, power failure, cooling water failure, steam failure, gas leakage, and storm etc.)

- Planned for fire emergency?

- Planned for Disaster emergency? (Explosion, flood, tank rupture, earthquake, riot/strike etc.)

- Is safety manual ready and given to all concerned?

- Are all workers trained for these emergency operations?

Checkpoints for Medical Check-up of workers and records:

- Pre-employment medical check-up? Record available? First-aid available?

- Place of work as per above report?

- Periodical medical check-up: At what interval? Forms maintained?

- Cases of occupational disease/poisoning detected & recorded? Reported to Authority?

- Name and address of the nearest Doctor/Hospital available?

- ESIC facility available for such occupational health check-up and treatment?

Checkpoints for Good Housekeeping

- Where cleanliness required?

- Lifting machinery safe moving?

- Tools etc. In safe position?

- Safety posters, precautionary notices in all rooms, floors displayed? Where more necessary?

- Motor, gears, pulleys, belts, chains, coupling etc. Guarded? What not guarded?

- Stairs, platforms, railing cover etc. Guarded? Where required?

- Ventilation (natural and mechanical) and lighting adequate? Where need more?

- Lunch room, canteen, clock-room, lockers, ambulance room, first-aid necessary? Provided?

- Are labels provided on all chemicals stored and manufactured?

- Other: (Process of fire and explosion hazards in separate room etc.)

Checkpoints for Personal Protective Equipment (PPE):

- Hazards to be faced

- Types given

- Types necessary : Chemical filter, mechanical filter, air-line respirator, suction hose mask, pressure hose mask, canister gas mask, helmet, face shield, safety goggle and type, leg guard and type, apron and type, full suit, safety belt, safety shoes, others.

Checkpoints for Fire Fighting Equipment (FFE):

- Hazard to be faced

- Types provided

- Types necessary: Water type, water type gas pressure, Foam type, CO2 type, Dry powder type, Hand & Stirrup pumps, water bucket, sand bucket, fire drills, No smoking notices, Flame traps, Auto sprinklers, Hydrants, Fire calling buttons on all floors or in each room.