Contents

SAFETY INDUCTION

The safety induction program is a medium to introduce the new workers about the site or workplace. The safety induction program is very important for new workers/employees, in this induction program, new workers/employees are given information about the site/workplace. In this program, the workers are told about the work to be done on the site and what is the danger/hazard in that work and their safety measures, what are the safety regulations on the worksite, first-Aid station location, Fire station, Emergency contact number, emergency assembly point, etc.

Some mandatory points must be covered in Safety induction program:

CLICK HERE FOR > TOOLBOX TOPICS

- Company Activity (Construction, production, maintenance, etc.)

- Company organization structure

- Company policy

- Work-site/workplace layout

- Company goal and achievement in safety

- Safety norms/regulation at the workplace

- Goverment law about safety

- Major hazards and their safety measures

- Mandatory/job-specific PPE

- Discuss on previous accident/incident

- Welfare facilities.

- Emergency Assembly point

- Emergency contact number

- First-aid station location

- Fire station location

Benefits of safety induction program:

- Workers understand the safety regulation and safety culture at work site

- Workers are educated company policy and norms

- Understanding of government law about safety

- Understanding what to do at the time of emergency

- Understanding worksite hazards and their safety measures

- Understanding company goal about safety

- Understanding overall safety requirements/PPE at the worksite.

SAFETY EDUCATION AND TRAINING

CLICK HERE FOR > SAFETY QUIZ

P. Blake has explained the difference of education and training. He says, “Education deals with developing the mind, broadening knowledge and understanding. Education in a specific subject means acquisition of broad and thorough knowledge in that subject. Training deals with the development of skill in performance.

In industry it refers to the skilled trades as applied to safety. Education and training are not completely separable; each participates to some extent of the nature of the other. Safety Education is for developing safety mindedness a vivid awareness of the importance and correcting conditions and practices that might lead to injury.

Safety training is for developing the worker’s skill in the use of safe work techniques and practices. It is described as a detailed extension of the educational safety programmed applied to specific occupation, processes, jobs or activities”.

Oatey (1970) defined training as “Any activity which deliberately attempts to improve a person’s skill at task”.

Hesseling (1971) defined it as a sequence of experiences or opportunities designed to modify behaviour in order to attain a stated objective.

Hamblin (1974) defined it as “Any activity which deliberately attempts to improve a person’s skill on a job as opposed to education which is concerned with personal development and no directly to the job”.

McCormic & Ilegen (1987) opined that of training is that “It is the management of It is an organized procedure which brings semi-permanent change in behaviour for a purpose”. When this definite purpose is “S defines “Safety Training”.

A functional definition of training acquisition of concepts, theories, knowledge, skilled & attitudes so that employees are equipped to competently in their present or future jobs resulting increase of efficiency of the organization as their own job satisfaction.

On the other hand “development” is d the application of acquired knowledge, theories and attitudes to the job for increasing organ effectiveness.

CLICK HERE FOR > HIRA AND JSA

Training is one way to develop a more and efficient work force. Modern technological is a driving force behind today’s training, e in technical areas. Modern technology also hazards and suggests remedial measures1 safety training is becoming more and more essential develop a skilled and motivated work understand and identify hazards, to find out the appropriate safety measures to main working conditions and actions. Safety Training is an extension of educational safety programmer applied to specific activities processes .viz. industrial activities, work on machines chemicals etc.

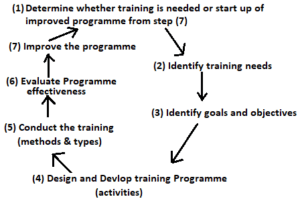

Elements of Training Cycle

As per OSHA (Occupational Safety Act)’s training guidelines, seven chronological suggested to complete a training cycle. The basic element of any safety training program shows them in a cyclic order.

These steps are explained as under:

- Determine if training is needed – The first step is to determine whether a problem can be solved by training. All skill deficiencies are not solvable through training and some other tool may be required. This step includes need of any improved (revised) training programme.

- Identify training needs – Analyze the worker’s duties and what he or she needs to perform the job more skilfully and safely.

- Identify goals and objectives – A list of Specific job knowledge and skill deficiency derived from step-2, will tell employers what workers should do, do better or stop doing.

- Design & Develop training programme – After listing precise objectives and goals, learning (training) activities must be identified and described. Type of training will be decided based on the training resources available to the employer, the kind of knowledge or skills to be learned end whether the learning should be oriented towards physical skill or mental attitudes.

- Conduct the training – Now the training programme should be conducted by (a) providing overviews of the material to be learned and (b) relating each specific item of knowledge or skill to the worker’s goals, interests or experience to be learned.

- Evaluate programme effectiveness – By knowing trainee’s opinion, supervisor’s observation, work place improvement, hazard reduction, performance improvement etc., it should be checked whether the training has accomplished its goals.

- Improve the programme – Based on feedback from the workers, supervisors etc., and from evaluation and observing the gap, the training programme should be improved (revised) as per need .

Assessment of Training Needs

The first step of any training. process (cycle) is to be sure about the needs. Following four questions (approaches) should be considered:

- Does an actual or potential performance discrepancy exist? (Unsafe conditions, actions, efficiency).

- Is it important to the organization? (in reduction of cost of accident, hazards; losses etc.).

- Is it important to the employees? (Basic training to new employees, refresher course for old employees, more mistakes by workers, more accidents to them)

- Is it correctable through training? (If yes, then only the training becomes useful and cost effective).

CLICK HERE FOR > SCAFFOLDING LOAD FORMULA

General training needs are assessed following grounds:

- New employees are not very clear about description. Therefore training is essentially required for them.

- Old employees require knowledge of new b new technology, process revision, new methods and forgotten old items. Training for emergency preparedness, safety audit, fire fighting, ha detection etc. are also necessary for them.

- Change of position due to promotion transfer. New position may require training.

- Technological changes in the organize Addition of new material, machine, method; process, equipment etc. create need of training.

- To make a person more versatile to do more one job (safety supervision, accident analysis and computer data feeding).

- When performance, productivity and efficiency fall down at any level, training may imp them.

- Supervisors/foremen feel need of training workers working under them.

- Records of production, turnover, accidents absenteeism, rejects, errors, wastes point areas of training. The safety training programme is gene needed for all the times. as an induction or introductory course or a refresher or ongoing.

Course specifically needed when-

- New employees are recruited

- New plant, material, process or equipment introduced

- When safety procedures are evolved or up

- New information of hazard is received

- Safety performance needs to be improved

- The accident rates are increased

- Labour turnover is increased and

- Excessive waste, rejects and scrap are noticed Under sections 7A (2) (C) and 111 A (ii) of the Factories Act new provisions are added for training to ensure the health and safety of all workers at This is statutorily required as under.

CLICK HERE FOR > SURAT FIRE CASE STUDY

Every worker shall have the right to get ft within the factory or at a training centre or ins duly approved by the Chief Inspector, where training is imparted for worker’s health and safety at work.

Four approaches are suggested to deter safety training needs as under:

| Approach | Content | |

| 1. | Common concepts approach. | Assess own situation/requirement based on real need. Specific result oriented programme instead of general knowledge. |

| 2. | Safety needs analysis approach. | Job Safety Risk Analysis useful. Gap between job requirement knowledge and employee knowledge suggests training need. |

| 3. | Problem Identification approach. | From employee’s performance appraisal report, his need can be assessed and fulfilled by personal coaching, instructing, guiding etc. |

| 4. | Organisational Safety survey approach. | Classify and analyse accident and calculate and compare performance rates. Conduct hazard survey Study existing safety measures, interview key personnel and arrive at needs and deciding priorities. |

Techniques (Procedure) of Safety Training

Competence Building Technique (CBT) The concept or basic object of any training is to generate or build competence in participants (workers only knowledge is not sufficient. Knowledge alone cannot give competence or confidence of safe successful working Knowledge should be put into practice by necessary training. Training shows practical part of knowledge and generates competence of work gradually.

Competence in safe working is necessary to advancement in technology, new process equipment, modification or changes, training i required to become familiar with this. Therefore is an online function. It should not end i slogan, suggestion, award or safety day celebration

It should be considered as a part of continuous or ongoing activities. For this purpose, ii training and refresher training are organized. Communication system should be utilized multimedia and computers should be utilize films, pictures, hazard points, accident case etc. should be shown and explained during.

A good safety training programme steps:

- Determine safety training needs and p by four approaches stated in above.

- Design training to meet the needs. The St (a) Assess training requirements (b) Determine training contents (c) Decide training Methods and aids (d) Organize training contents (e) Formulate training plan and (f) evaluations measures.

- Implement training process. The steps Discuss with company officials (b) administrative aspects and time schedule of training (c) Execute (give) training to the trainees (d) Monitor the programme( e) conduct review of safety training and (f) Have follow of trainees.

Techniques of training are generally the ‘1 methods” winch are discussed in detail in P following. All these training (teaching) classified into two types of techniques off-the-job training techniques and on-the-job techniques:

CLICK HERE FOR > NEAR-MISS EXAMPLE

(A) Off-the-job training techniques:

| Category | Techniques | |

| 1. | Information presentation techniques (less involvement of trainee). | Reading list, Correspondence course, Films, Lecture, Panel discussion, programmed or Computer based instruction. |

| 2. | Information processing techniques (trainees are involved). | Conference or discussion group, T (training) group. |

| 3 | Simulation techniques (experiment or practise). | Incident/case, role playing, In-basket, Vestibule, Mock-up, Business game. |

(B) On-the-job training techniques:

| Category | Techniques | |

| 1. | Actual job assignment. | Coaching, Job instruction training (JIT). |

| 2. | Temporary job assignment. | Special assignment on job, committee, project etc. Job rotation through predetermined set of jobs to provide exposure to different part of the organisation. |

Design and Development of training programme:

Following general points are useful in designing and developing any training programme.

- Motivation should be the first condition of any type of training.

- Number of lessons and content to teach should be well designed beforehand. Steps or sequence of topics should be decided.

- The amount to be taught in an unit (period) should not be too large or too small.

- An objective of the training should be decided and the training process should move toward it.

- The training procedure should be developed. A list of training aids should be prepared.

- The task to be performed should not be described only but it should be demonstrated in actual or simulated conditions. “Doing” is important than mere “Hearing” or “Seeing”. Practice makes perfect.

- The demonstration (by teacher) should be followed by the learner (trainee) as soon as possible before he forgets it. The teacher should be given feedback or knowledge of results.

- Questions of learners should be properly replied and discussed at all stages (steps).

- Ample practice opportunity should be provided and practice encouraged.

- Frequent and accurate knowledge with examples, pictures, practical etc., speeds up learning rate and motivation.

- The training should be taken to the point of goal and not be left unfinished.

- Effectiveness of the training should be evaluated and conclusion be drawn to revise (improve) the training programme and it should be followed in the next cycle.

According to Gagne, any human task (including safety) can be analyzed into a set of component (Job Safety Analysis). The design of any training should consist:

- Identifying the component tasks of a performance.

- Ensuring (in training) that each of these is fully achieved or mastered by the learn

- Arranging the training of the task compo:

in such a way that there will be positive transfer from learning of one to another.

The design work may be done by spec designated training professionals, especially programs to be offered several times or left to individual instructors.

CLICK HERE FOR > HYDRA SAFETY

Main design steps include

- Set instructional objectives

- Determining programme content and

- Selecting instructional technique off-the-job and on-the-job training

Training Method & Strategies

Aspects and Goals : The training methods two aspects

- Theoretical or formal in the classroom an

- Practical or informal in the job place. There are two basic goals (a)To explain the worker to know the job or do it correctly and (b) To be certain that he knows how to c correctly.

Steps: Any training method should have following steps:

- Lay down the objective of the training: programme.

- Prepare the training programme.

- Brief the trainee.

- Use audio visual aids where appropriate.

- Review the contents and

- Follow up with trainees when the programme completed.

Effects of Methods: Effectiveness of diff training methods is given by Bird as follows:

A trainee tends to remember 10% of what reads, 20% of what he hears, 30% of what he sees, of what he sees and hears, 70% – of what he sees talks and 90% of what he says as he does a thing. Percentage is variable depending upon one’s me power, intelligence, grasping, understanding susceptibility and interest in the subject. It depends upon the explanation power. These factors can be developed by education and training. Speaking writing, involving and doing are the most effective exercises to digest any subject.

Types of Methods: Some usual methods Lecture method, discussion method, case study, play, project work, programmed instruction, on-the job instruction, training aids, fault analysis, algorithm as an aid to fault analysis, fault tree analysis, drill, demonstration, panel or group discussion, meeting, simulation, pictures and posters, films and closed circuit television, filmstrips and slides, projectors and microphones, charts, boards, and working models, checklists, exercise, rehearsal and use of press and other mass media. Thus methods are many from old to the ultramodern. Which method is the best? No one method can be named. Appropriate method should be selected depending upon the size, age and experience of the group, the amount of material, type of presentation necessary and time and money available. Selection of method requires skill and experience. Result of effectiveness depends upon it. Therefore make the best choice of the method and apply it successfully. Display of relevant safety posters at workplaces contribute much without saying.

CLICK HERE FOR > RIGGING AND ERECTION SAFETY

Some common methods in use are mentioned

- Lecture Method: Oldest arid most basic method. Well planned lectures can cover a large amount of information in a short time. More useful when participants are more, or their involvement is less required.

- Discussion Method: Useful with small number of people in a group. The trainer acts in a limited way as a scene setter or referee encouraging participants to speak out. The two-way communication moves toward objectives. Participants are more attentive, active and don’t feel boredom.

- Case-study Method: Accident case study is presented explaining how an actual accident happened or an imaginary accident can happen. Causation analysis and remedial measures can be discussed by questions and answers. Good pictures are more useful to explain the situation effectively.

- Role playing method: It is a form of learning by doing but in a simulated situation. Trainees are given a situation like in case-study method but instead of just discussing it they resolve the problem by acting out the roles of the people involved. Here extrovert trainees show their skill but introvert or shy trainees unused to such situation get embarrassed.

- Business Games Method: More useful for business people and skill required for safety attitude or inspection in buying/selling items which are safer or with the details of safety.

- Sending at training Centres: Institutes, seminars, workshops, special courses etc. utilises external resources for required training.

- Job instruction training: Useful to train supervisors who in turn train the employees. Job instruction training (JIT) involves four steps (a) Preparing the trainee (b) Demonstrating the job (c) Having the trainee performed the job and (d) Checking frequently the trainee’s performance. All new job assignment should be preceded by on-the-site job training. Each step of job safety analysis (JSA) is explained with hazard, safe procedure and use of safety equipment. Use of guards and controls are also explained.

- Programmed instruction: Programmed instructions are given in a book from. A trainee learns it, answers the question or solves the problem. The system has mechanism of learning-checking and relearning.

- Project work: Project writing is given to trainees. They apply their knowledge to practical situation.

- Other methods: Job rotation, committed assignments, HRD training, sensitivity training, creativity training, in-basket training etc. are other specific methods.

Types of Safety Training:

Types of safety training are formal and informal

Formal training may be general or specific.

General Training includes-

- Induction courses for new employees.

- On-going safety training.

- Safety representative training.

- Supervisor training.

- Senior/middle management training and

- Direction training.

Specific Training includes-

- Safety system of work for particular operations where the potential hazard is high and guarding is not feasible.

- First aid training.

- Specific items of plant or equipment.

- Use of protective equipment.

- Fire precautions.

- Safety inspection.

- Change of job for which a worker is not trained.

- Role of workers in emergency planning.

- Techniques of safety audit, Hazop, Hazan, FTA, ETA etc.

- Safety permit system.

Some details are given below:

- Orientation or Induction Training: It is obvious that new employees may not be knowing much about the factory that they joined, its safety policy, specific raw-materials, their characteristics, process, methods, pollution control, health check-ups, role in emergency planning, first-aid, fire fighting, use of personal protective equipment, accident record, hazards of their work, remedial measures and workplace monitoring etc. Therefore it is always useful to design training on such subjects for the new employees. This basic knowledge builds their confidence, skill and interest towards the work and the company both.

- Apprenticeship Training: A learner who has just completed his school or college education or is still undergoing it and agrees to work as a trainee or apprentice or employed under the Apprenticeship Act as an statutory requirement, is given this type of training. It is a combination of on the job and off-the-job training taking the strengths of both. Intention is to show him the practical or applied pert fitting to his type of education.

- On-the-job training is practical in nature and generally takes place on the job. Such job contact sessions may involve individual on one to one basis with the supervisor training an operator for the work he has to carry out.

First the supervisor are trained for this purpose showing them the job safety or risk analysis. Then in turn they train the employees mostly new. It imparts necessary skill for the job involving worker to do the job systematically and safely. Injury to the trainee or the job is possible due to normal mistake of the trainee. Therefore its usage is limited to situations where mistakes can be tolerated: Airline pilots and Surgeons are allowed on the job practice only after their skills have been sharpie honed using off the job simulation techniques.

Some methods used in this type of training are coaching (personal attention), job instruction training (JIT), special assignment and job rotation.

CLICK HERE FOR > HYDRO TESTIONG SAFETY

It is supervisor’s or training instructor’s responsibility to train the employees under him for safe methods, machine guarding, identification of hazards in each step and its remedial measure, need and use of safety equipment, avoidance of shortcut, hasty actions, overconfidence etc.

- Off-the-job training: All types except on-the-job are called off-the-job training. It includes class room or lecture method, audio-visual, film, reading list, books, correspondence course, panel discussion, conference or discussion group, T (training) group, computer based instruction, case study, role playing, in-basket, vestibule, mock-up, business game etc. and explained as “training methods” earlier.

- Vestibule Training: It is an approach between on-the-job and off-the-job training and used when the job is dangerous and can harm the trainee if taught on the job. The training takes place away from the actual work place but the equipment and procedure to be followed are similar to be used on the job.

Evaluation & Reviewing of Training Programme

An evaluation i.e. measurement of effectiveness or result of the training programme conducted useful in reviewing the programme content, method aid and redesigning the programme as per feed for improvement. An effective training program should show:

- Increase in quantity and quality of production.

- Increase in production rate.

- Increase in knowledge, skill and ability about performance.

- Increase in job satisfaction and motivation.

- Decrease in accident rate.

- Decrease in production time, breakage or u consumable items.

- Decrease in absenteeism.

- Decrease in labour turnover.

- Decrease in job turnover.

- Decrease in operational cost.

- Refinement of human behaviour tow intended objective or goal viz, safety outlook interest and safety mindedness, production quality orientation etc.

The benefits of value measurement of safety training programme are:

- The top management understands useful and cost effectiveness (in relation to accident costs) of the training programme.

- Confidence, morale, skill, status, prestige of the employees and the company itself are improved.

- Most effective loss prevention measures ca segregated for repetition.

- Strengths and weakness are highlighted suggest the steps for next programme.

- Safety professional can find out and promote most effective programmes.

- It can be determined whether objectives! Goals are met and reason of gap if any. This is useful in reviewing the programs.

For evaluation participant and/or supervisors reaction should be assessed through interviews or questionnaires. Following questions are useful in such assessment.

- How much change occurred? The criteria include knowledge, attitudes, skills, behavioural change on the job and/or improvements or decrements in organizational results. These criteria can be measured by paper and pencil tests, questionnaires, work sample tests, timings of performance etc.

- Can the change attributed to the training programme?

- Was the training worth the effort? Here cost of training is justified against gain to the organization.

- Whether employee development needs are fulfilled?

This can be judged through effectiveness, efficiency and affirmative action and helps to guide decisions concerning planning, programming and budgeting.

Assessment is carried out by using Rating, standards and rating norms (poor, fair, and good, excellent) are prescribed and marks are given. Activity standards can be decided for (1) Organization & Administration (2) Industrial hazard control (3) Fire control (4) Health and Hygiene (5) Participation, motivation and training (6) Accident investigation, statistics & reporting procedure etc.

CLICK HERE FOR > GRINDING SAFETY

After evaluation, its results should be utilized to review the programme. Such review will give (1) Agreed recommendations for future action (2) An agreed action plan for the department (3) A follow-up and action plan for agreed recommendation.

After review a new (improved) safety (training) programme will take shape with drawbacks filtered ok and more effectiveness and usefulness reinforced. This process of refinement of better and better training programme yields good results.

Hi

Thanks sir

This website is very helpful

All ditel’s