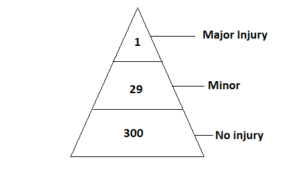

Heinrich estimates that in a unit group of 330 accidents of the same kind and involving the same person, considering average of averages, 30 result in no injuries, 29 in minor injuries and I in major lost time injury.

It indicates an ample opportunity to prevent any injury by efforts during 300 no-injury or warning accident. This foundation of a major injury is shown in this picture.

Heinrich’s Theory:

H.W Heinrich, a pioneer in safety first published his work, Industrial Prevention, in 1931. Many of his principles a philosophy of accident causation and prevention are confirmed by time and application, but, some questioned and criticized. His philosophy is I his 10 axioms (self evident truths) as follow:

Ten Axioms of Industrial Safety:

- The occurrence of an injury invariable from a completed sequence of factors – One of these being the accident its accident in turn is invariably permitted directly by the unsafe act of and/or a mechanical or physical hazard.

- The unsafe acts of persons are response a majority of accidents.

- The person who suffers a disabling injury caused by an unsafe act, in the average had over 300 narrow escapes from serious as a result of committing the very same act. Likewise, persons are to mechanical hazards hundreds of time they suffer injury.

- The severity of an injury is largely fortuitously the occurrence of the accident that re-injury is largely preventable.

- The four basic motives or reasons occurrence of unsafe acts provide a guide selection of appropriate corrective measures these are: Improper attitude, Lack of knowledge or skill, Physical unsuitability and improper mechanical or physical environment.

- Four basic methods are available for preventing accidents. These are engineering revision, Persuasion and appeal, Personnel adjustment and Discipline.

- Methods of most value in accident prevention are analogous with the methods required for the control of the quality, cost and quantity of production.

- Management has the best opportunity and ability to initiate the work of prevention; therefore it should assume the responsibility.

- The supervisor or foreman is the key man in individual accident prevention. His application of the art of supervision for the control of work performance is the factor of greatest influence in successful accident prevention. It can be expressed and taught as a simple four step formula – Identify the problem, find and verify the reason for the existence of the problem, select the appropriate, remedy and apply the remedy.

- The humanitarian incentive for preventing accidental injury is supplemented by two powerful economic factors:

CLICK HERE FOR > HIERARCHY OF CONTROL

- The safe establishment is efficiently productive and the unsafe establishment is inefficient.

- The direct employer’s cost of industrial injuries for compensation claims and for medical treatment is about one-fifth of the total (direct plus indirect) cost which the employer must pay.

These axioms were the first set of principles or guidelines ever set before in industrial safety and it has guided all safety activity till today.

During the passage of 75 years, some of his axioms are questioned and disbelieved as truths, but most of them are still true and deal with the important areas of safety, viz.

Accident causation and prevention, reasons of unsafe acts and conditions, management control functions, responsibility of organization, cost of accident, safety and productivity etc.

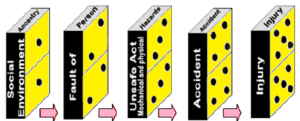

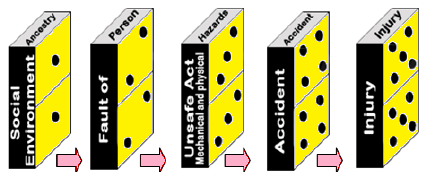

Accident Sequence: Tue five factors in accident occurrence series in chronological order are:

- Ancestry and social environment.

- Fault of person.

- Unsafe act and/or. Mechanical or physical hazard.

- Accident and

- Injury.

One factor is dependent on another and one follows because of another, thus constituting a sequence that may be compared with a follows because of another, thus constituting a sequence that may be compared with a row of dominoes placed on end and in such alignment in relation to one another that the fall of first domino precipitates the fall of the entire row.

CLICK HERE FOR > Frank Bird’s Domino Theory

An accident is merely one factor in the sequence. If this series is interrupted by the elimination or withdrawal of even one of the five factors that comprise it, the injury can possibly be prevented.

In above domino, social environment includes family and surrounding atmosphere in which a person is born and brought up. This is the origin or root cause of behavioral development as per H.W. Heinrich.

Undesirable traits include unsafe behaviour, negligence, lack of knowledge, violent temper, nervousness, recklessness etc.

CLICK HERE FOR > Petersen’s Incident Causation Theory

Unsafe act or conditions are the result of undesirable traits.

Accident is caused because of unsafe act or condition or both.

Injury is the result of accident.

This suggests the steps of management controls as under:

Management Through Supervision |

Controls

Human Failure Knowledge – Attitude – Fitness – Ability |

| Unsafe Acts of Persons | Unsafe Mechanical, Chemical, Physical Conditions | |

| 1. | Operating without authority or clearance, failure to secure or warn. | 1. Unguarded, absence of required guards. |

| 2. | Operating or working at unsafe speed. | 2. Inadequate support or guards, guards of improper height, strength, mesh etc. |

| 3. | Making safety devices inoperative. | 3. Defective, rough, sharp, slippery, decayed, cracked surfaces etc. |

| 4. | Using unsafe or defective equipment or equipment unsafely or improperly. | 4. Unsafe design of machines, tools, plant, equipment or supplies. |

| 5. | Unsafe loading, placing, mixing, combining etc. | 5. Unsafely arranged. Poor housekeeping, congestion, blocked exists, etc. |

| 6. | Taking unsafe position or posture. | 6. Inadequately lighted, sources of glare etc. |

| 7. | Working on moving or dangerous equipment. | 7. Inadequately ventilated, impure air source etc. |

| 8. | Distracting, teasing, abusing, startling horseplay etc. | 8. Unsafely clothed, no goggles, gloves or masks, wearing high heels etc. |

| 9. | Failure to use safe affair or personal protective equipment or devices. | 9. Unsafe processes, mechanical, chemical, electrical, nuclear hazards etc. |

| 10. | Failure to warn co-workers or to secure equipment. | 10. Inadequate warning systems. |

| 11. | Improper lifting. | 11. Fire & Explosion hazards. |

| 12. | Servicing equipment in motion. | 12. High noise or vibration. |

| 13. | Use of drugs or alcohol. | 13. Hazardous dusts, gases, fumes, vapours etc. |

The Economic Times, Mumbai of 21/09/1997 gave following figures of Railway accidents:

| Year | 1992-1993 | 1993-1994 | 1994-1995 | 1995-1995 | 1996-1997 |

| Failure of Railway Staff | 363 | 358 | 351 | 237 | 249 |

| Failure of other persons | 60 | 72 | 76 | 71 | 59 |

| Other cause | 101 | 90 | 74 | 88 | 73 |

| TOTAL | 524 | 520 | 501 | 396 | 381 |

This supports Heinrich’s conclusion that human failure is the predominate cause of accidents. However, this is not necessarily applicable to all or majority of the industrial accidents as per other theories.

CLICK HERE FOR > SAFETY OFFICER INTERVIEW QUESTIONS

To find out rate of human failure, software “Technique of Human Error Rate Prediction (THERP)” is available.

Criticism of Heinrich’s Theory and His Reply

H.W. Heinrich ratio theory (fact finding from a study of 75000 accidents cases) that 88% accidents are due to unsafe acts, 10% due to unsafe conditions and 2% unpreventable is criticized as follows.

Heinrich made his analysis from reports submitted to insurers by the managers of the companies at which the accidents happened.

No manager would want to indicate to insurer or the safety authority or agency that the company had been at fault and that hazards existed in the workplace under his control.

This ratio idea is fallacious because it rest on a false assumption that accidents are result of either unsafe acts or unsafe conditions. Actually there are multiple (combined) factors as supported by the results stated below.

CLICK HERE FOR > HIRA AND JSA

A study conducted by the National Safety Council (USA) yielded the following conclusions:

18% injuries due to mechanical causes.

19% injuries due to personal causes.

63% due to combination of both causes.

A study by the Department of Labour and Industry of the State of Pennsylvania yielded the following:

3% due to mechanical causes.

2% due to unsafe acts.

95% due to a combination of both causes.

(adsbygoogle = window.adsbygoogle || []).push({});

The ratio idea had done much harm and many employers still say, why should first of all we spend a lot of money on only 10% mechanical causes?

We will start after 88% personal causes are removed by the employees, such concept is damaging. There are two essentials in every case of injury – there must be some degree of hazard and there must also be faulty behavior by someone.

CLICK HERE FOR > SWL AND SAFETY FACTOR

If the factor of hazard is properly detected and eliminated, there could be no injury. Similarly, if behavior could be made and kept perfect, the result would be the same.

Both these are the duties of every management. It must try collectively to combat the combined causes of accident and should not separate the unsafe acts as employee’s responsibility only. Law always stresses for employer’s responsibility first.

Why? Because the primary duty money and ultimate control lie with the management to detect and remove unsafe conditions actions and to give necessary training to the workers. This is the only safe healthy approach.

Heinrich is aware about the public debate and criticism of his 88-10-2% ratio in accident causation stated above and its wide spread that may influence people to ignore the machine guarding and to take the assumedly easier path of issuing instructions.

CLICK HERE FOR > GRINDING SAFETY

In reply, he states his belief that the accident-prevention like almost all professional groups, want all the pertiment facts and he has more faith in their good judgement than to fear that they will ignore the very first common-sense step of safeguarding mechanical environment. The machine is dangerous as man makes it so. Its man’s use of the machine more correctly, his abuse of it-that create danger.

He points out that judgement must be used in selecting the major cause when a mechanical hazard and an unsafe act both contribute to accident occurrence. Personal judgement may lead to error, but it is defensible and in the majority of cases results in fair conclusions.

The 300-29-1 Ratio (Foundation of lost-time accident – Explaining the foundation of a major injury), Heinrich estimates that in a unit group of 330 accidents of the same kind and involving the same person, 300 result in no injury, 29 in minor injuries and 1 in a major lost-time injury.

He explains this 300-29-1 ratio as an aid accident prevention, because, it vividly emphasis’s preventive opportunity, when an employee, either because of his repeated unsafe action or repeated exposure to an unsafe mechanical condition, suffers 300 no-injury accidents (actual events such as slips and falls but fortunately not causing injury) surely there can be no lack of opportunity in preventive effort.

CLICK HERE FOR > EXCAVATION SAFETY

Replying misunderstanding and misquotation of this ratio, he states that this ratio is an average. Sometimes a major or serious injury occurs the very first time a person acts unsafely or is exposed to mechanical hazard-in other cases he is so endangered hundreds or thousands of times and may slip or fall many times before injury is sustained.

In industry where employees are under supervision, these unsafe practices, conditions and the resulting narrow escapes events-accidents are tangible and visible. They can and should be controlled long before one of the 300 no-injury accidents ultimately causes an injury.

In above ratio – cases, a major injury is any case that is reported to insurance office or to the State Compensation Commissioner. A minor injury is a scratch, bruise, or laceration such as is commonly termed a first-aid case.

A no-injury accident is an unplanned event involving the movement of a person or an object, ray, or substance (slip, fall, flying object, inhalation etc.), having the probability of causing personal injury or property damage but not resulted in injury (near miss).

CLICK HERE FOR > HYDRA CRANE SAFETY

Safety and Productivity – Citing the study made by the Committee on Safety and Production of the American Engineering Council, Heinrich has narrated the detail findings some of which are given below:

- Industrial accidents can be controlled under modern conditions of highly efficient productivity.

- Efforts to improve safety performance do not interfere with production.

- Maximum productivity is ordinarily secured only when the accident performance tends toward the irreducible minimum.

- The cost of accident is a loss in industrial operation, which should not be neglected.

CLICK HERE FOR > HYDRO TESTING SAFETY

PLEASE SHARE THIS ARTICLE WITH YOUR FRIENDS

good

Right sir

Right sir

Right sir

Thank you

Thank you!!