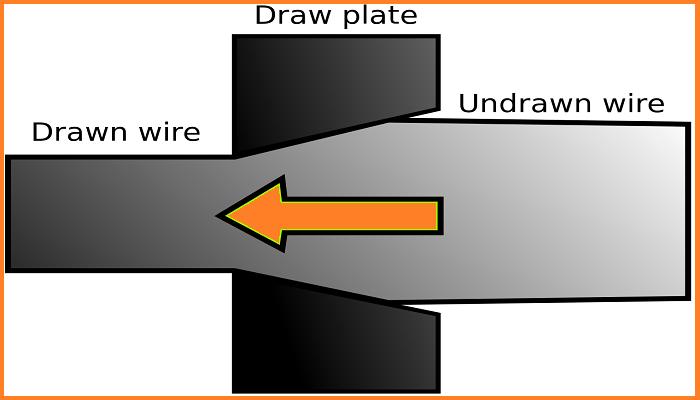

The usual meaning of wire is a coiled metallic stock up to 3/8 inch cross-sectional width. Wire drawing is cold working in which semi-finished metal rod stock is transformed into wire of smaller diameter and perfectly round cross-section by pulling it through a die or dies. The operational diagram is shown below.

Wire Drawing

The annealed or patented wire can further be subjected to acid clean, water wash, coating, and redrawing. In the end, the wires kept into wire stock or used for products. The drawn wire may be galvanized or tinned before delivery. During wire drawing operation either the wire is passed through dry lubricants (soap or sodium, calcium or aluminum stearates) or wet lubricants (soap solution, paraffin, etc.) in which the dies are fully immersed for maximum lubrication and cooling which also gives a bright clean finish.

Hazards are acid splashes, burns, cuts, bruises, falling forging bodies into the eye, skin diseases due to acid, dust, scale and lubricants and lead poisoning due to the lead bath which is not covered or has no fume extraction.

Preventive Measures include guarding of dangerous moving parts, drive, nips, wire pully nips and feed points by screens and barriers (adequate to contain a broken wire), enclosure of dangerous chemical process, removal of fumes and dust by exhaust ventilation, use of personal protective equipment (Safety helmets, goggles, face masks, gloves, aprons, footwear), safety material handling, training, barrier creams and medical examination of workers.