Contents

Safety precautions for sulfur recovery plant

SAFETY IN SULFUR RECOVERY PLANT

- 1-People working in sulfur pelletizing and packaging rooms should wear Anti-static clothing and protective mask.

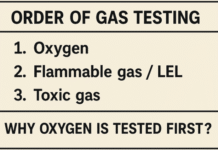

- 2-Persons doing routine field inspection should be equipped with CO, H2S, NH2 detector, and at least two people should stay together.

- 3-In sulfur recovery unit, people should keep body sideways when opening/closing Valves to prevent from being burnt by steam or sulfur.

- 4-No iron made tools allow when loading/unloading the sulfur to prevent from Sparks which may cause an explosion. Transportation of sulfur should abide with regulation for the transportation of hazardous chemicals.

- 5-Sulfur should be kept away from kindling, heat source, oxidant, phosphorus, chlorinate and nitrate; it should be stored in shady, cool and ventilated place, away from moisture and damage.

- 6-People who accidentally ingest sulfur should apply warm water from emesis and then quickly get sent to the hospital

- 7-No smoking, eating and drinking in the sulfur work field, take a shower after work for sanitation.

- 8-All dark room requires good ventilation to control the level of acetic acid vapors and sulfur dioxide gas produced.

- 9-Cover all both when not in use to prevent evaporation or release of toxic vapor/gases.

- 10- Wear PPE as per mention in MSDS.

SULFUR- FLAMMABLE SOLID (MSDS)

SAFETY IN SULFUR RECOVERY PLANT

Burn sulfur emit toxic and suffocating sulfur dioxide (SO2), molten sulfur may evolve toxic and flammable hydrogen sulfide gas (H2S). Molten sulfur can cause burns. Solid and molten sulfur can be ignited. Dust particles may be irritating to eye, nose, throat, and skin.

Molten sulfur may evolve H2S which may be accumulated in storage container vapor space. High concentration may cause immediate unconsciousness and may result from death unless the victim is promptly and successfully resuscitated.

H2S cause eye irritation. Sulfur dust suspended in air may be ignited by friction, static electricity, heat, sparks or flame and cause an explosion.

PHYSICAL AND CHEMICAL PROPERTIES

SAFETY IN SULFUR RECOVERY PLANT

purity 99.5%

color palette yellow pellet

Solubility in water-insoluble

Sp. Gr.- 2.07

Boiling point 444c°

Melting point 110-120c°

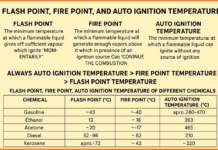

Auto-ignition temperature 232-266c°

Flashpoint- 207c°

Flammable limit- LEL: 35 gm/m³, UEL: 1400gm/m³.

HEALTH HAZARD

Symptoms of exposure noise or throat irritation, coughing, chest discomfort, asthma, difficulty breathing, nausea, vomiting, eye irritation, skin irritation.

FIRST AID MEASURE

SAFETY IN SULFUR RECOVERY PLANT

- Skin contact may cause irritation, remove clothes, wash skin with plenty of mild soap and water.

- Eye contact may cause eye irritation, flush eyes with plenty of water, wear safety glasses.

- Inhalation of a large amount of dust may cause irritation of the respiratory tract. Move patient to crash air. If difficulty in breathing provide oxygen. If the person is not breathing than start mouth to mouth resuscitation. If the heart has stopped breathing than start CPR. Immediately send the person to first aid.

FIRE AND EXPLOSION

Flammable solid with relatively low ignition temperature. Sulfur dust suspended in air may be ignited by friction, static electricity, heat, spark or flame and cause the explosion. Burning sulfur will flow and emit the large quantity of SO2 a toxic, irritating and suffocating gas. Molten sulfur may evolve H2S, a flammable and toxic gas. Use water spray and foam to extinguish the fire. Do not use the solid stream of water as it can create sulfur dust clouds and may cause an explosion. The cool surrounding area to prevent re-igniting. In case of large fire, fireman should use self-contained breathing apparatus.

SPILL CONTINGENCY

Be careful not to create dust. Fulminate source of ignition. Use natural fiber broom or non-sparking. Shower to clean up the spillage. Wear proactive clothing clean-up: safety glasses, rubber gloves, impervious clothing, dust mask or respirator.

First aid for chemical burns

- Ensure that area is safe and that you are protected from the chemical. this may involve wearing personal protective equipment (PPE).

- locate the material safety data sheet (MSDS). this will include details of PPE requirements and specific first aid procedure. remove all contaminated clothing.

- The burn area should be flooded with water for 30 minutes to ensure that there is no contamination from the chemical to other areas of the body.

- All chemical burns require professional medical advice following first aid treatment.

“If you have any issue regarding SAFETY IN SULFUR RECOVERY PLANT please comment below”