Contents

Safety Precautions & Operation for Boilers

SAFETY IN BOILER

DON’T

- Operate a boiler which is not certified by a Boiler Inspector.

- Operate a boiler unless it is equipped with a safety valve, with sufficient relieving capacity, set at or below the maximum allowable working pressure.

- Ever bypass the pressure controls, low water cut-out or any other limit switch or control.

- Ever restrict the design function of any safety valve, such as by reducing or plugging the outlet, painting or removing it.

- Permit unqualified personnel to operate a boiler.

- Ever leave the boiler unattended for long time periods.

- Operate a boiler without an adequate source of combustion air.

- Operate a boiler without a valid certificate of inspection.

DO

- Respect the boiler. It can be dangerous!

- Have the vessel inspection internally annually, as required by State law.

- Report newly installed boilers to the State Office of Boiler Inspectorate.

- Test safety controls and devices on a periodic basis (as recommended by CSD1).

- Ensure boiler operators are adequately trained to assure safe and efficient operation.

- Inspect the boiler daily for proper operation, and/or adverse conditions.

- Maintain a log of incidents that effect boiler operation, and when safety controls and devices were tested (low water cut-out, safety valves, combustion controller).

- Allow only authorized repair firms to make welded repairs.

- Have you burner serviced immediately, if the burner starts with a puff or operates in an unusual manner?

Preservation of boilers when not in use

- Steam boiler when not in use are liable to deterioration from corrosion and unless well cared for and made rust proof.

- They should be thoroughly drained, thoroughly dried.

- All valves, cocks, and openings closed so as to exclude moisture.

- Another method is to fill the boiler with water to which about 1/100 percent caustic soda has been added.

Long-term preservation

For shutdown exceeding one month or more, dry preservation techniques are preferred. These dry techniques fall into two categories.

- Open and dry preservation

- Close dry preservation

Open and Dry Preservation:

Elimination of all moisture is the primary objective of dry preservation because as long as the boiler and other metal surfaces remain dry, no significant corrosion can occur. Air in contact with moisture is extremely corrosive and water leakages into the unit or sweating of surface must, therefore, be avoided.

- The boiler should be drained completely, thoroughly cleaned on both fireside and water side.

- All internal surfaces should be dried, by circulating warm air or some heating device such as heating lamps or resistant heaters in the boiler drum and furnace.

- The boiler should be left open for free circulation of air.

- During dry preservation, the boiler should be inspected for any condensation.

Closed Dry Preservation:

The closed dry preservation is useful when the plant atmosphere contains corrosive fumes and or abrasive dust which could enter the open dry boiler.

- It is also generally useful in humid coastal areas.

- Similarly as mentioned above under open dry preservation, the boiler and

- Superheater should be drained and dried with warm air.

- Trays containing drying agent such as quicklime (calcium oxide CaO) activated alumina or silica gel should be placed in boiler drum and furnace to absorb any moisture present.

- The recommended amount of drying agent per one cubic meter of boiler volume is 0.907kg of quicklime 2.27 kg of silica gel.

- Silica gel is preferred drying agent because it can be easily regenerated by heating 2 to 4 hours at 325 to 350-degree centigrade, and it has high moisture absorption capacity. It absorbs 30%its.

Precautions before starting the fires:

Before starting the fires in the boiler, the attendant should-

- See that there is sufficient water in the boiler and that the gauge cocks are working freely.

- Ease safety valves, or open cock on top of the boiler to allow air to escape.

- See that the blow-off cock is fully closed and tight.

- See that the safety valves and feed check valve are free and workable.

- Note if the pressure gauge pointer is at zero.

- See that the feed pump is in working order.

- In addition, the boiler attendant should not rely on the supposition that the water he has previously put in is still in the boiler as

- It may have run out without the knowledge through a leak, or

- Open cock.

- The gauge glass may not show the true level until he has tested it.

Types of Boilers

Two principal types of boilers are used for industrial applications:

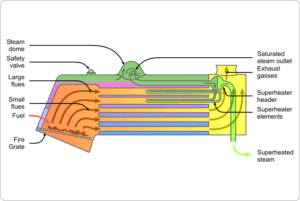

Fire tube boilers: Product of combustion pass through the tubes, which are surrounding water.

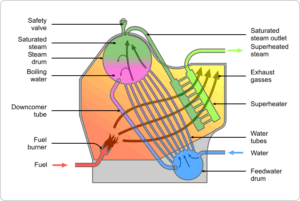

Water tube boiler: Products of combustion pass around the tubes containing water. The tubes are interconnected to common channels or headers and eventually to a steam outlet for distribution to the plant system.

External treatment of Boiler

- External treatment as the term is applied to water prepared for use as boiler feed water, usually refers to the chemical and mechanical treatment of the water source.

- The goal is to improve the quality of this source prior to its use as boiler feed water, external to the operating boiler itself.

Such external treatment normally includes

- Clarification

- Filtration

- Softening

- Dealkalization

- Demineralization

- Deaeration

- Heating

Any or all of these approaches can be used in feed water or boiler water preparation.

Internal treatment Boiler

- Even after the best and most appropriate external treatment of the water source, boiler feed water (including return condensate) still contains impurities that could adversely affect boiler operation.

- Internal boiler water treatment is then applied to minimize the potential problems and to avoid any catastrophic failure, regarding of external treatment malfunction.

- Boiler Pressure Gauge

- In order to detect the steam pressure within the boiler, a pressure gauge is fitted.

- This is a mandatory requirement and always fitted directly to the boiler.

- A cock is usually fitted to allow changing of the gauge should it become defective.

- It made from phosphor bronze.

- The dial has a scale and is usually marked off in Pounds per Square Inch. (LBf/in2) though sometimes it may have a dual scale marked in Bars, usually in increment of ten.

- On every boiler gauge, there is marked a Redline on the scale, this is the maximum working pressure of the boiler and point at which the safety valves will lift.

THANKS FOR BOILER SAFETY

Thanks for these boiler safety tips. I had no idea that fire tube boilers have combustion pass through tubes surrounding water. I’m curious to learn how these are set up effectively so that the boiler can work.