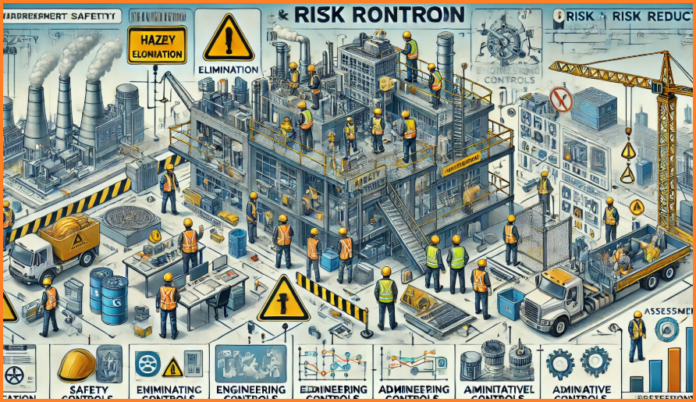

Hazard control and risk reduction are fundamental aspects of workplace and environmental safety. The most universal approach today involves a structured procedure that ensures hazards are identified, assessed, controlled, and monitored effectively. This process is most important to prevent accidents, injuries, and other adverse events.

Contents

Step 1: Hazard Identification

The first step in the process is hazard identification. This involves recognizing and documenting potential hazards present in the workplace, environment, or system. One can apply various concepts, theories, and models to effectively identify hazards, including:

- Reviewing activities, conditions, and circumstances that contribute to hazards.

- Conducting workplace inspections and audits.

- Evaluating historical incident reports and near-miss data.

- Engaging employees and experts in hazard recognition exercises.

- Identifying and evaluating potential consequences of undesired events.

By thoroughly analyzing these factors, organizations can pinpoint potential risks before they escalate into serious incidents.

Step 2: Risk Assessment

Once hazards are identified, the next step is risk assessment. This involves evaluating the likelihood and severity of potential hazardous events. Key aspects of risk assessment include:

- Determining the probability or frequency of hazard occurrence.

- Assessing the severity or impact of the hazard on people, property, and the environment.

- Analyzing event patterns, such as whether the hazards are intermittent or continuous.

- Using risk matrices or other assessment tools to quantify risk levels.

By systematically assessing risks, organizations can prioritize which hazards require immediate attention and resource allocation.

Step 3: Implementing Risk Controls

After assessing risks, the next step is to implement appropriate risk control measures. The prioritization of controls follows the Hierarchy of Controls, which includes:

- Elimination – Removing the hazard entirely.

- Substitution – Replacing hazardous materials or processes with safer alternatives.

- Engineering Controls – Implementing physical changes to reduce exposure, such as barriers or ventilation systems.

- Administrative Controls – Establishing policies, procedures, and training to minimize risk.

- Personal Protective Equipment (PPE) – Providing protective gear, such as gloves, masks, and helmets, as a last line of defense.

Using this hierarchy ensures that the most effective controls are implemented first, reducing reliance on less effective methods like PPE.

Step 4: Reviewing and Evaluating Controls

The final step in hazard control and risk reduction is the continuous review and evaluation of implemented control measures. This ensures that the controls remain effective over time and adapt to changing conditions. Regular reviews may include:

- Conducting audits and inspections.

- Gathering feedback from employees and stakeholders.

- Monitoring incident and near-miss reports.

- Updating control measures as necessary to improve safety outcomes.

By maintaining an ongoing evaluation process, organizations can ensure that hazard controls remain relevant and effective in reducing risks.

Hazard control and risk reduction are vital for ensuring safety and preventing accidents in various environments. Following a structured approach that includes hazard identification, risk assessment, implementation of controls, and continuous review enables organizations to create safer workplaces and minimize potential risks effectively. By adhering to the Hierarchy of Controls, organizations can prioritize safety measures to ensure the best possible protection for workers and stakeholders.