Atmosphere of an area containing any flammable gas or vapor in in concentration capable of ignition is called hazardous zone or area.

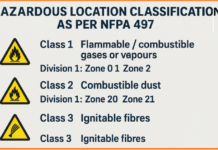

Classification of hazardous zone/Area

All hazardous zone/area have been divided mainly in to three zones.

ZONE – 0

ZONE – 1

ZONE – 2

According to the extent of risk involved.

ZONE 0 – An area in which flammable atmosphere is present continuously or present for a long period.

ZONE 1 – An area in which flammable atmosphere is likely to present occasionally or periodically during normal operation.

ZONE 2 – An area in which flammable atmosphere is likely to occur during normal operation and if it occurs is exist for a short period.

Various sources have tried to place time limits on to these zones, but none have been officially adopted. The most common values used are:

- Zone 0: Explosive atmosphere for more than 1000h/yr

- Zone 1: Explosive atmosphere for more than 10, but less than 1000 h/yr

- Zone 2: Explosive atmosphere for less than 10h/yr, but still sufficiently likely as to require controls over ignition sources.

Where people wish to quantify the zone definitions, these values are the most appropriate, but for the majority of situations a purely qualitative approach is adequate.

When the hazardous areas of a plant have been classified, the remainder will be defined as non-hazardous, sometimes referred to as ‘safe areas’.

The zone definitions take no account of the consequences of a release. If this aspect is important, it may be addressed by upgrading the specification of equipment or controls over activities allowed within the zone. The alternative of specifying the extent of zones more conservatively is not generally recommended, as it leads to more difficulties with equipment selection, and illogicality in respect of control over health effects from vapors assumed to be present. Where occupiers choose to define extensive areas as Zone 1, the practical consequences could usefully be discussed during site inspection.

Factors that could be considered during an on site inspection:-

- If there are any large areas of zone 1 on the drawings, is there evidence that by design and operation controls, the sources of release and consequently the location and extent of hazardous areas have been minimised?

- Do any zone 2 areas extend to places where the occupier has inadequate control over activities that could create an ignition source, or is there any suggestion that the zone boundaries have been arbitrarily adjusted to avoid this?

- Has ignition protected electrical equipment been installed and maintained by suitably trained staff.

- Are the risks from static discharges controlled properly? Earthing of plant, drums and tankers is the most basic requirement; other precautions are described in the references