In the industrial pre-commissioning activities, ensuring the safety of every step is very important. One such crucial aspect is cardboard blasting, a process that demands meticulous attention and adherence to safety procedure. This blog post explores the importance of cardboard blasting safety during pre-commissioning activities, emphasizing the measures and precautions that must be taken to protect workers and property.

Cardboard Blasting in Pre-Commissioning:

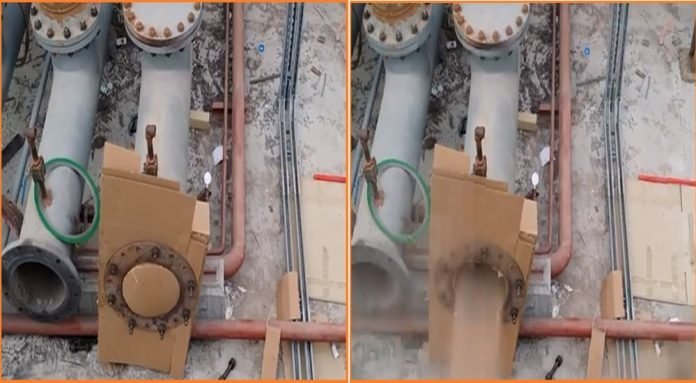

Cardboard blasting is a method commonly employed during pre-commissioning activities in industries such as oil and gas, petrochemicals, and power plants. The purpose of cardboard blasting is to remove mill scale, rust, and other contaminants from newly fabricated piping systems, vessels, and equipment. This preparatory step ensures a clean surface, promoting optimal performance and longevity of the installed components.

Importance of Safety in Cardboard Blasting:

While cardboard blasting is an effective method for surface preparation, it comes with inherent risks that cannot be ignored. Safety during cardboard blasting is crucial to prevent accidents, injuries, and damage to equipment. The pre-commissioning phase is the foundation for the operational life of the facility, making it imperative to prioritize safety measures during each step of the process.

Key Safety Measures:

- Personnel Protective Equipment (PPE): Providing and ensuring the use of appropriate PPE is the first line of defense. This includes but is not limited to safety helmets, goggles, ear protection, gloves, and respiratory protection. The selection of PPE should be based on the specific hazards associated with cardboard blasting, such as flying debris and dust.

- Work Area Enclosure: Cardboard blasting activities should be conducted in enclosed work areas to contain debris and prevent it from dispersing into the surroundings. This not only protects nearby personnel but also minimizes the risk of environmental contamination. Adequate ventilation is essential to control the concentration of airborne contaminants generated during cardboard blasting. Properly designed and maintained ventilation systems help in ensuring that workers are not exposed to harmful levels of dust and fumes.

- Training and Certification: Only trained and certified personnel should be allowed to carry out cardboard blasting activities. Training programs should cover the safe use of blasting equipment, recognition of potential hazards, and emergency response procedures. Regular refresher courses can help reinforce safety practices.

- Equipment Inspection and Maintenance: Regular inspection and maintenance of cardboard blasting equipment are required to ensure that it operates safely and effectively. Any malfunctioning or damaged equipment should be promptly repaired or replaced to prevent accidents.

- Secure Hoses and Connections: Ensure that hoses and connections between the compressor and the cardboard blasting equipment are securely fastened. Loose or damaged connections can lead to air leaks, posing a safety hazard.

- Communication: Effective communication is key to preventing accidents during cardboard blasting. Clear communication channels should be established among team members, and a designated person should be responsible for coordinating the blasting activities, ensuring everyone is aware of the ongoing work.

- Pressure Regulation: Set and regulate the compressor pressure to the recommended levels for the cardboard blasting operation. This prevents over-pressurization, which could lead to equipment failure, and ensures a controlled and safe blasting process.

- Noise Control: If the compressor generates significant noise, implement noise control measures, such as using noise barriers or providing hearing protection, to minimize the impact on workers’ hearing health.

- Emergency Response Plan: An emergency response plan should be in place, detailing procedures to be followed in case of accidents, injuries, or equipment malfunctions. This plan should be communicated to all personnel involved in pre-commissioning activities.

Cardboard blasting, when conducted with a strong emphasis on safety, plays an important role in the success of pre-commissioning activities. Prioritizing the safety of personnel and safeguarding the integrity of equipment and the environment are non-negotiable aspects of any industrial operation. By implementing and adhering to safety measures, organizations can ensure that cardboard blasting contributes to the overall success and reliability of their facilities. It’s not just about completing a task; it’s about doing so with the utmost commitment to the safety of everyone involved.