Wire rope slings are widely used in lifting operations across industrial, construction, and engineering environments. Their reliability and strength are very important for safe material handling. One essential aspect of sling integrity is the method used to form the eye connection at the end of the wire rope. This connection directly affects the load-bearing capacity and long-term durability of the sling.

Requirement for Flemish Eye Mechanical Connections

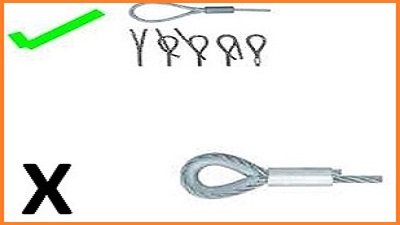

All wire rope slings must be manufactured using a Flemish eye mechanical connection to form the sling eye. The Flemish eye method involves separating the wire rope strands, wrapping them around a thimble, and then reweaving them back into the body of the rope before applying a steel sleeve (ferrule) for secure compression. This creates a strong and reliable termination that retains a high percentage of the rope’s original strength.

Advantages of Flemish Woven Mechanical Eye

- Provides superior strength and durability

- Prevents slippage during heavy lifting

- Maintains structural integrity under dynamic loads

- Recommended for critical lifting operations and certified lifting slings

- Offers increased safety as the woven structure distributes load evenly

The image depicts the Flemish woven mechanical eye as the correct and acceptable standard practice, indicated with a green check mark.

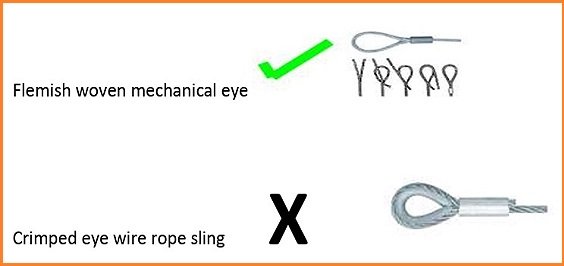

Prohibition of Crimped Fold-Over Eye Connections

Crimped or fold-over eye connections are strictly prohibited for lifting slings. In this method, the wire rope is simply bent back to form an eye and secured only by crimping. This design lacks internal structural weaving and significantly weakens the sling at the eye termination point.

Risks Associated with Crimped Eye Wire Rope Slings

- Reduced load-bearing capacity

- High risk of wire rope failure at crimped section

- Susceptible to slippage, loosening, or cracking under stress

- Not recommended for any certified lifting operations

- Often fails safety inspections and lifting compliance audits