Lifting operations involving cranes and rigging equipment require systematic planning and execution to ensure safety. Even a routine lift can become dangerous without proper controls, making categorization and lift planning essential. This article consolidates the key requirements from the provided bulletin and aligns them with Indian Standards (IS codes) and international practices such as ASME, ISO, OSHA, and BS EN.

Contents

Lift Categories

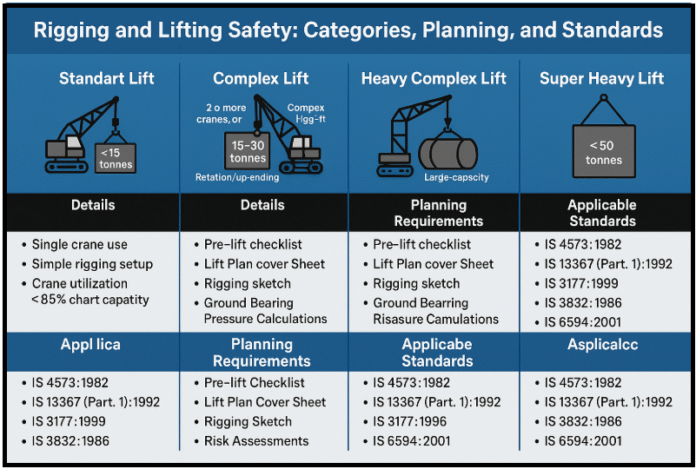

Lifts are classified into four categories, each requiring a different level of planning:

- Standard Lift

- Payload < 15 tonnes

- Single crane use

- Simple rigging setup

- Crane utilization < 85% of chart capacity

- Complex Lift

- Payload 15–30 tonnes

- Use of two or more cranes, or complex rigging arrangement

- Rotation/up-ending of loads

- Crane utilization ≥85%

- Lifts over live plants or critical infrastructure

- Heavy Complex Lift

- Payload 30–49 tonnes

- Use of large-capacity cranes (>200t)

- Higher emphasis on ground bearing pressures, pad design, and rigging selection

- Super Heavy Lift

- Payload ≥50 tonnes

- Requires detailed lift plan with oversight from senior engineers and project management teams

Planning Requirements

Every lift must be backed by appropriate documentation and checks. Typical requirements include:

- Pre-Lift Briefing Checklist (as per OISD practices for heavy lifts in oil & gas sector)

- Lift Plan Cover Sheet with payload details, location, and approval signatures

- Rigging Sketch showing crane setup, exclusion zones, radii, and obstacles

- Bill of Materials for Rigging (slings, shackles, spreader bars) with Working Load Limit (WLL)

- Ground Bearing Pressure Calculations compared with allowable site values

- Risk Assessments covering weather, nearby utilities, and power lines

Roles and Responsibilities

Clear roles are defined for safe execution, aligned with IS 4573:1982 (Safety code for erection of lifting appliances) and ASME B30 standards:

- Lift Plan Creator – prepares lift plan (Rigging Engineer or qualified person)

- Lift Plan Checker – reviews plan for technical accuracy

- Responsible Engineer (EPCM/Owner) – approves lift plan before execution

- Rigging Engineer / Superintendent – final oversight of high-risk lifts

- Person-in-Charge (PIC) – supervises lifting team during operation

- Rigging Team – includes riggers, operators, and signalers; each member has authority to stop the lift if unsafe

Applicable Standards

Indian Standards (Relevant to Rigging & Lifting)

- IS 4573:1982 – Safety code for erection of lifting appliances

- IS 13367 (Part 1):1992 – Safe use, inspection, and testing of lifting appliances

- IS 3177:1999 – Code of practice for overhead cranes and gantry cranes

- IS 3832:1986 – Hand-Operated Chain Pulley Blocks

- IS 6594:2001 – Technical requirements for wire ropes used with cranes

International Standards

- ASME B30 Series – Covers cranes, rigging hardware, slings, shackles, hooks

- ISO 9927-1:2013 – Cranes, inspections and safe use requirements

- OSHA 29 CFR 1926.1400 – US crane and derrick safety in construction

- BS EN 13155:2020 – Safety of lifting accessories

Safety Measures Before and During Lifting

- Conduct pre-lift checks: crane stability, ground condition, wind speed (stop work above 36 km/h or as per manufacturer).

- Maintain safe clearance from overhead powerlines (minimum 6–10 m as per IS/OSHA).

- Only trained signalers in high-visibility vests may guide crane operators.

- Never exceed 85% of crane rated capacity unless an approved lift plan is in place.

- Use mats or pads to reduce ground pressure under outriggers.

- Conduct mock lifts for complex and super heavy lifts.

Safe lifting operations demand careful categorization, detailed lift planning, and strict adherence to Indian and international standards. By enforcing rigorous documentation, assigning competent personnel, and carrying out thorough risk assessments, organizations can prevent incidents and maintain safe working conditions during rigging and lifting activities.