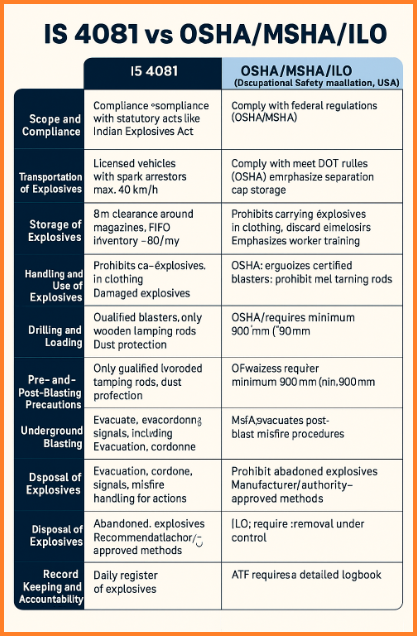

Comparison to international standards such as OSHA (USA), MSHA (USA), and ILO guidelines.

Contents

Safety in Blasting and Related Drilling Operations

(Based on IS 4081:2013 with International Comparisons)

Blasting and drilling are critical operations in construction, tunneling, quarrying, and infrastructure development. However, these activities pose high risks such as premature explosions, flying debris, toxic fumes, misfires, and transportation hazards. To minimize these risks, standards and codes of safety have been developed worldwide.

In India, the Bureau of Indian Standards (BIS) has codified the IS 4081:2013 (Second Revision) which provides comprehensive safety guidelines for blasting and related drilling operations outside of mines. Internationally, similar guidelines are issued by organizations like OSHA (Occupational Safety and Health Administration, USA), MSHA (Mine Safety and Health Administration, USA), and ILO (International Labour Organization).

Key Provisions of IS 4081:2013

1. Scope and Compliance

- Applicable to blasting and drilling operations in locations other than mines.

- Requires mandatory compliance with statutory acts like the Indian Explosives Act, 1884 and Explosives Rules, 2008.

- Similar to OSHA/MSHA requirements which mandate compliance with federal explosive regulations (29 CFR Part 1910, Subpart U; 30 CFR Part 56/57).

2. Transportation of Explosives

- Vehicles must be licensed, spark-arrested, insulated, and clearly marked with “EXPLOSIVES.”

- No refueling during transport, CO₂ fire extinguishers mandatory.

- Speed limits: 25 km/h on rough roads, 40 km/h elsewhere.

- International comparison:

- OSHA requires vehicles to meet DOT (Department of Transportation) hazardous material rules, with placards and secure containment.

- ILO also emphasizes separation of detonators and explosives during transport, a requirement also present in IS 4081.

3. Storage of Explosives

- Explosives stored in approved magazines: clean, ventilated, lightning-protected, and guarded.

- Safe distance (8 m clearance) around magazines, prohibition of smoking/open flames.

- FIFO (First-In, First-Out) principle for inventory.

- International comparison:

- MSHA mandates explosives magazines to be bullet-resistant, fire-resistant, and theft-proof, which aligns with IS 4081.

- OSHA requires daily inventory records and safe separation of blasting caps from main storage.

4. Handling and Use of Explosives

- Prohibition of smoking, open flames, or rough handling.

- Explosives not to be carried in clothing.

- Damaged/wet explosives must be discarded.

- International comparison:

- OSHA also prohibits carrying explosives in clothing and mandates manufacturer’s disposal procedures for damaged explosives.

- ILO emphasizes worker training and restricting access to authorized personnel.

5. Drilling and Loading

- Blasting operations must be supervised by qualified blasters.

- Surplus explosives not allowed near worksite.

- Only non-sparking wooden tamping rods allowed.

- Respiratory protection required in dusty conditions.

- International comparison:

- MSHA requires certified blasters and mandates wet drilling or dust suppression.

- OSHA explicitly prohibits metal tamping rods consistent with IS 4081.

6. Electrical Shot-Firing & Fuses

- Electric blasting caps must be tested before/after tamping.

- Circuits must be insulated; blasting switches must be lockable.

- Safety fuse minimum length: 750 mm; burning rate ≤ 600 mm/min.

- International comparison:

- OSHA/MSHA specify minimum fuse lengths (90 seconds burn time in USA, equivalent to ~900 mm).

- IS 4081’s requirements are very similar, though U.S. standards often require longer delays for larger blasts.

7. Underground Blasting

- Only permissible explosives allowed.

- Adequate ventilation must remove toxic gases after blasting.

- ILO/OSHA/MSHA also enforce post-blast ventilation and monitoring of carbon monoxide/nitrogen oxides.

8. Pre- and Post-Blasting Precautions

- Danger zones must be evacuated and cordoned off.

- Warning sirens and signals required before/after blasting.

- Misfires must be handled by re-drilling nearby or carefully flushing out stemming.

- International comparison:

- MSHA mandates misfire procedures, including re-firing or controlled disposal.

- Both IS and OSHA emphasize no re-entry before a specified time (IS: 5–30 minutes, OSHA: minimum 15 minutes in surface blasting).

9. Disposal of Explosives

- No explosive should be abandoned. Disposal must follow manufacturer or authority-approved methods.

- Packing material destroyed by burning.

- International comparison:

- ILO/OSHA both require disposal in remote, controlled conditions under supervision.

10. Record Keeping and Accountability

- Daily register of explosives must be maintained.

- Only competent, authorized personnel can requisition explosives.

- International comparison:

- ATF (Bureau of Alcohol, Tobacco, Firearms & Explosives, USA) mandates detailed logbooks and traceability.

- IS 4081 is aligned with this international best practice.

IS 4081:2013 provides framework for safe blasting and drilling operations, aligning closely with global standards (OSHA, MSHA, ILO). Its strength lies in:

- Clear segregation of transport, storage, handling, and disposal procedures.

- Specific rules for electrical and fuse blasting.

- Strong emphasis on competent supervision, training, and statutory compliance.

While the standard aligns well with international norms, some improvements could be adopted, such as:

- Enhanced use of blast monitoring systems (vibration, noise, fly-rock) as per EU standards.

- Stricter limits on maximum charge per delay to reduce ground vibrations (common in UK’s BS 5607 standard).

- Mandatory post-blast toxic gas monitoring, as enforced by MSHA.

Overall, IS 4081:2013 is comparable to the best international practices and ensures worker and public safety when rigorously implemented.