Working at heights is one of the most hazardous tasks in industries such as construction, maintenance, and infrastructure. Falls from elevation account for a large share of workplace injuries worldwide. To safeguard workers, organizations must adopt systematic measures of fall prevention and protection, guided by national and international standards.

Contents

Why Fall Protection Matters

Falls can occur from roofs, ladders, scaffolds, mobile platforms, or even unguarded floor openings. These incidents not only risk severe injury but can also lead to loss of life. Proper fall protection ensures that workers operate in a secure environment, improving overall productivity and safety culture.

Key Elements of Fall Protection

1. Engineering Controls

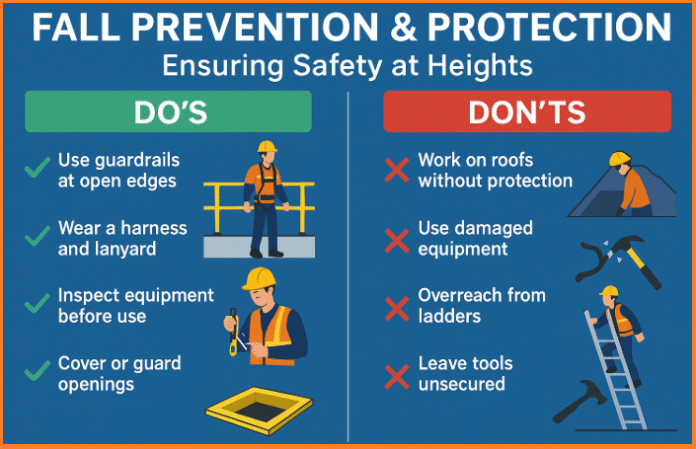

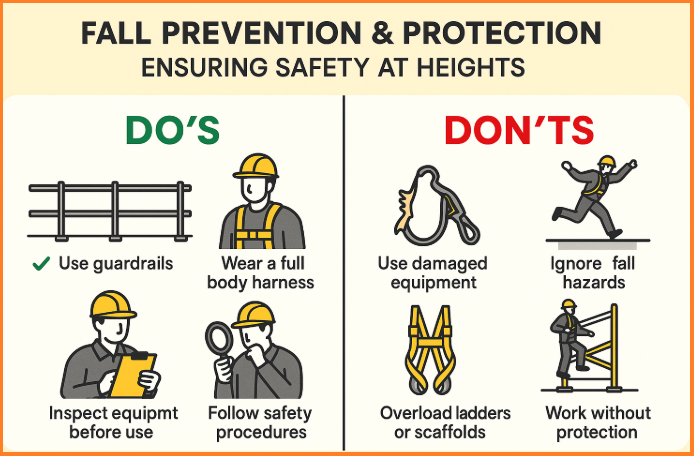

- Guardrail Systems: Primary defense for open edges, walkways, and elevated platforms.

- Permanent Platforms/Walkways: Built with handrails and load-tested for structural integrity.

- Anchorage Points: Designed to withstand minimum loads as per standards (e.g., 22.3 kN in OSHA 29 CFR 1926 Subpart M).

2. Personal Fall Arrest Systems (PFAS)

- Full body harness with shock-absorbing lanyards or self-retracting lifelines.

- Equipment must limit free fall to a maximum of 1.8 meters.

- Regular inspection and certification are mandatory before use.

3. Work at Ladders and Scaffolds

- Fall protection is required at 1.8 meters and above.

- For scaffolds, tie-off to independent anchorage is essential during erection or dismantling.

- Mobile elevated platforms must have harness attachment to designated anchor points.

4. Roof Work

- On steep roofs, guardrails or PFAS are mandatory.

- On low-slope roofs, use of warning lines, safety monitors, or controlled access zones may be permitted under specific conditions.

5. Protection from Falling Objects

- Use of toe boards, mesh, or screens to prevent tools and materials from falling.

- Workers below elevated activities must be shielded using barricades or canopies.

Equipment Inspection & Training

- Pre-use checks: Users must visually inspect harnesses, lanyards, and lifelines.

- Periodic inspections: Competent persons conduct quarterly checks following manufacturer’s guidelines.

- Training: Workers should be trained to identify fall hazards, use protective systems, and follow rescue procedures.

Emergency Response

Every worksite must have a rescue plan. Workers suspended after a fall must be retrieved promptly to prevent suspension trauma. Trained personnel and suitable rescue equipment are essential components of the plan.

Standards & Regulations

Fall protection requirements align with global safety guidelines, including:

- Indian Standards (BIS) – e.g., IS 3521: Safety belts and harnesses, IS 3696 Part 1 & 2 for scaffolds and ladders.

- OSHA (USA) – 29 CFR 1926 Subpart M, Fall Protection.

- European Union Directives – Workplace Safety & Health Directives.

- UK Construction Regulations 2007.

- Australian National Codes of Practice for fall prevention.

Best Practices for Employers

- Conduct a fall hazard assessment before work.

- Always prefer prevention (guardrails, covers) over PPE.

- Keep inspection records up to date.

- Engage trained supervisors (“Competent Persons”) to monitor work.

- Ensure emergency rescue systems are tested and ready.

Final Note

Fall prevention is not just about compliance — it is about saving lives. By combining engineering controls, personal protective systems, training, and international best practices, industries can create safer working environments for everyone.