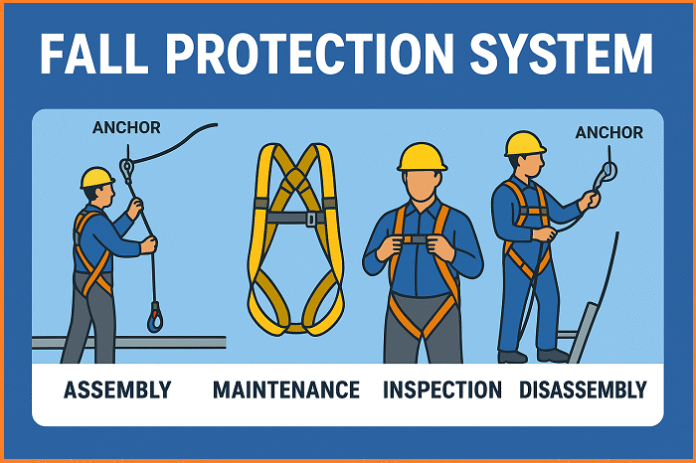

Fall protection systems such as full-body harnesses, lifelines, anchor points, guardrails, safety nets, and fall arrest devices are critical components for safeguarding workers operating at height. To ensure their effectiveness, each system must be properly assembled, inspected, maintained, and safely disassembled according to established standards.

This article provides a comprehensive guide to following correct procedures throughout the lifecycle of fall protection equipment.

Contents

1. Assembly Procedure for Fall Protection Systems

1.1 Planning and Pre-Assembly Checks

- Conduct a pre-job hazard analysis to identify fall hazards and required fall protection levels.

- Select appropriate equipment certified as per relevant standards (e.g., IS/ANSI/EN).

- Ensure all components—harnesses, connectors, lifelines, SRLs, anchor devices—are compatible and approved by the manufacturer.

- Verify that assembly will be done under competent person supervision.

1.2 Assembly of Personal Fall Arrest Systems (PFAS)

- Inspect all equipment before assembly for wear, defects, or certification validity.

- Ensure the anchor point is rated for minimum 22.2 kN (5,000 lbs) or manufacturer’s requirement.

- Connect full body harness correctly by:

- Adjusting leg straps, chest straps, and D-rings.

- Ensuring snug but comfortable fit.

- Install lifelines or self-retracting lifelines (SRLs) securely onto approved anchors.

- Use only manufacturer-recommended connectors, carabiners, and shock absorbers.

- Maintain required free-fall distance, clearance distance, and swing fall prevention.

1.3 Assembly of Collective Fall Protection (Guardrails, Safety Nets, etc.)

- Follow manufacturer’s assembly drawings and torque requirements.

- Guardrails must include:

- Top rail (at required height),

- Midrail,

- Toe board (where applicable).

- Ensure safety nets are installed:

- As close as practicable below the work level.

- With correct tensioning and edge attachments.

2. Inspection Procedure

Fall protection equipment must undergo three levels of inspection:

2.1 Pre-Use Inspection (User Level)

Before each shift, the worker must check:

- Harness webbing for cuts, burns, fraying, chemical damage.

- Stitching for loose or broken threads.

- D-rings and buckles for cracks, corrosion, distortion.

- Connectors and hooks for proper locking.

- Lanyards for shock absorber deployment marks.

- Lifelines for fiber damage, wire frays, kinks.

- SRLs for locking function and smooth payout.

- Anchor points for deformation or looseness.

If any defect is found—tag out and remove from service immediately.

2.2 Frequent (Periodic) Inspection

- Conducted monthly by a competent person.

- Inspection must follow manufacturer checklist.

- All equipment should be logged in an inspection register.

2.3 Annual Thorough Examination

- Conducted by a certified competent person or third-party inspector.

- Proof load testing may be required for anchor systems.

- Documentation should be maintained for audits.

3. Maintenance Procedure

Proper maintenance enhances performance and increases equipment lifespan.

3.1 Cleaning

- Clean harnesses and webbing using mild soap and water.

- Do not use bleach, harsh chemicals, or high-pressure washes.

- Dry equipment in a shaded, ventilated area—never in direct sunlight.

3.2 Lubrication and Mechanical Care

- Lubricate metal components (where allowed) using manufacturer-approved lubricants.

- Keep SRLs free from dirt and contaminants.

- Do not open SRL casings unless authorized service personnel are involved.

3.3 Storage

- Store equipment:

- In cool, dry, dust-free areas.

- Away from chemicals, oils, flames, or sharp objects.

- Properly hung or stored in a dedicated HSE cabinet.

3.4 Repair

- Never repair fall protection equipment in-house unless explicitly allowed.

- Only manufacturer-authorized technicians can repair or recertify specialized devices.

4. Disassembly Procedure

4.1 Pre-Disassembly Safety Checks

- Ensure the system is not under load.

- Confirm all workers are safely off elevated surfaces.

- Inform the work crew about system removal.

4.2 Disassembly Steps

- Disconnect lifelines and SRLs carefully to avoid recoil hazards.

- Remove harnesses and lanyards after ensuring no entanglements.

- Dismantle guardrails and safety nets in the reverse order of installation.

- Lower heavy components using proper lifting devices to avoid dropping hazards.

4.3 Post-Disassembly Inspection

- Check all components for wear or damage caused during dismantling.

- Tag defective components and send them for repair or disposal.

4.4 Documentation

- Update asset registers after disassembly.

- Record any defects, replacements, or disposal activities.

5. Disposal of Fall Protection Equipment

Equipment must be permanently removed from service if:

- It has been involved in a fall incident.

- It shows physical defects or fails inspection.

- Manufacturer guidelines state it has reached end-of-life.

Dispose of equipment so it cannot be reused by mistake (e.g., cutting webbing, marking “NOT FOR USE”).

6. Training Requirements

All personnel must be trained in:

- Proper donning and doffing of harnesses.

- Anchor selection and connection techniques.

- Rescue procedures after fall arrest.

- Use, inspection, and reporting protocols.

Competent and trained persons should supervise assembly and inspections.

A fall protection system is only effective when properly assembled, thoroughly inspected, well-maintained, and safely disassembled. Following manufacturer guidelines, regulatory standards, and competent supervision ensures the highest level of safety for workers at height. Comprehensive documentation, training, and disciplined implementation reinforce a strong safety culture and prevent fall-related incidents.