- Selection of proper material of construction for a new vessel/reactor, and modification.

- Proper design and fitting of vessel/reactor as per standard codes. Small bath size desirable.

- Operating conditions at less pressure, temperature, flow, slow reaction rate and less hazards desirable.

- Condition monitoring and pressure testing of vessels and equipment.

- Safety fittings like Pressure gauge, Temperature gauge, Rupture disc, Level indicator, Non return valve, Excess flow valve, interlocks, alarm and trips. Flameproof fitting where required.

- Safe operating procedure and safe close down procedure displayed for operator.

- Batch sheet design and full filling with details.

- Fire fighting equipment.

- Use of personal protective equipment.

- Open space maintenance space and leakage checking.

- Scrubber connections and scrubber working.

- Safe columns, condensers, receivers and vent and safety valve for distillation process.

- Auto and manual devices to stop heating, charging etc, and quenching or safe transfer of material in case of emergency.

- Close transfer/charging of hazardous material.

- Local exhaust ventilation on toxic material charging, transfer and filling/packing.

- Double earthing and static charge eliminator where required viz. Solvent in a glasslined vessel.

- Proper piping and colour code.

- Checking of proper O2/N2 lines and cylinders to avoid accident.

- Use of safety work permit.

- Machine guarding for drives, pumps etc.

Checkpoints for Pollution Control

(A) Effluent Treatment Plant (ETP)

- NOC and comment from Pollution control board.

- Norms suggested by Pollution control board like pH, BOD, COD, Oil & grease, Colour odour, suspended solid, total dissolved solid, heavy metals etc. Fill the format of logbook.

- Norms prescribed under the Factories Act (Schedule-2). Fill the format.

- Drawing approval of ETP.

- Continuous operation of ETP.

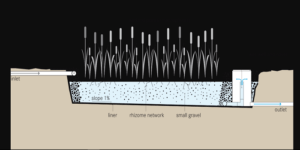

- Primary and secondary treatment plants.

- Continuous monitoring of parameters for final discharge from factory premises.

- Whether pollutant being discharged above prescribed limit?

(B) Gas Emission/Leak Control

- NOC and consent from Pollution control board.

- List emission/leaking points, pollutants and their prescribed limits.

- Selection of proper scrubbing media.

- Proper design and continuous working of scrubbers/flare/incinerator etc.

- Final vent gas detector with alarm and discharge valve.

- Whether pollutant being discharged.