Wire ropes are widely used in lifting, hoisting, and construction industries. To secure the ends of these ropes, devices such as bulldog grips provide a simple and effective mechanical fastening method. The Indian Standard IS 2361:2002 (third revision) by the Bureau of Indian Standards (BIS) lays down the specifications, material requirements, dimensions, and application guidelines for bulldog grips.

Bulldog grips serve as an alternative to splicing or socketing where skilled labor or specialized facilities may not be available. They are particularly useful for temporary ropes and for ropes requiring length adjustments. However, they are not intended for mine hoisting ropes or permanent crane rope attachments.

Contents

Scope of the Standard

The standard applies to bulldog grips designed for wire ropes with diameters ranging from 8 mm to 41 mm. For ropes larger than 41 mm, “double throat” type grips are generally recommended.

Material Specifications

Bulldog grips consist of three key components: U-bolt, nuts, and bridge.

- U-Bolts

- Manufactured from steel (class 1A designation 15C8 of IS 1875).

- Heat-treated (normalized) at 880–910°C, followed by air cooling.

- Nuts

- Must comply with IS 1367 (Part 6) – Class 4 properties.

- Typically, hexagonal as per IS 1364 (Part 3).

- Bridge

- May be made of steel casting, malleable iron casting, spheroidal graphite iron, or steel drop forgings.

- Must meet strength requirements (e.g., IS 1030 for steel casting, IS 1865 for spheroidal graphite iron).

- Bridges should be smooth, free from burrs, and shaped to grip ropes securely.

Form and Dimensions

- The nominal size of a bulldog grip corresponds to the diameter of the rope it is intended for.

- For intermediate rope sizes, the next larger grip size must be used.

- Dimensional tolerances are allowed up to +5% of minimum values specified in the standard.

A bulldog grip is designated by:

- Method of manufacture: Forged (F) or Cast (C)

- Coating: Galvanized (G) or Not Galvanized (NG)

- Nominal rope diameter in mm

- Standard number (IS 2361)

Example:

A forged, hot-dip galvanized bulldog grip for a 20 mm rope → Bulldog Grip F × G × 20 IS 2361

General Requirements

- Bridges must be free of sharp edges to prevent rope damage.

- U-bolts must be properly formed and heat-treated.

- Grips must be inspected for flaws before approval.

- Unless specified, bulldog grips are supplied assembled and oiled (threads coated with non-drying oil).

- Galvanizing (hot-dip process as per IS 2629) is optional, but when used, zinc should contain at least 98.5% purity.

Testing and Inspection

- Galvanizing Test: Conducted as per IS 2633, based on purchaser requirements.

- Inspection Rights: Purchasers can inspect grips at the manufacturer’s works.

- Sampling: As per IS 1367 (Part 17).

Application of Bulldog Grips (Annex B)

Correct application is critical to safety and efficiency:

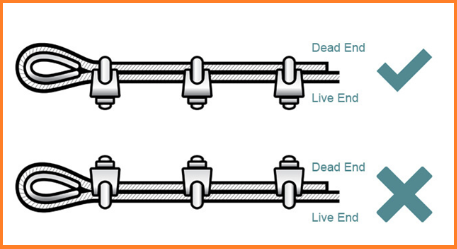

- Correct Placement

- The bridge must always be placed on the working (live) part of the rope.

- The U-bolt should grip the dead end (tail) of the rope.

- Grips should not be alternated in direction.

- Number of Grips Required

- Up to 20 mm rope → 3 grips

- 21–32 mm rope → 4 grips

- 33–38 mm rope → 5 grips

- 41 mm rope → 6 grips

- Spacing

- Grips must be spaced at about six times the rope diameter.

- Efficiency

- When properly applied, a bulldog grip termination can retain 85–90% of the rope’s breaking strength.

- Inspection After Loading

- Connections should be checked after initial loads, as nuts may loosen and require tightening.

- The grip closest to the thimble/eye should not be overtightened, as it is the most vulnerable point.

Marking and Certification

- Grips must be marked with nominal size and manufacturer’s identification.

- They may also bear the BIS certification mark, subject to licensing under BIS rules.

Safety Notes

- Improper application (placing the U-bolt on the live rope) can severely reduce rope strength.

- Not suitable for mine hoisting or permanent crane ropes.

- Regular inspection is mandatory to ensure safety in use.

Bulldog grips are an essential component in the safe and temporary securing of wire ropes, especially in construction, lifting, and rigging applications. The IS 2361:2002 standard ensures that bulldog grips meet strict quality, material, and safety requirements. Correct application is vital, as improper installation can drastically weaken rope strength and lead to accidents.

By following the guidelines of IS 2361:2002, industries can ensure safe, reliable, and standardized use of bulldog grips in their operations.