Excavation and trenching activities are among the most hazardous operations in construction and industrial projects. Without proper planning, design, and implementation of safety measures, these activities can lead to serious accidents such as cave-ins, falls, equipment hazards, and exposure to harmful atmospheres. This article outlines the essential practices and guidelines that ensure excavation and trenching work is carried out safely and efficiently.

The primary objective of excavation, trenching, and shoring guidelines is to safeguard workers by establishing clear procedures for planning, executing, and monitoring these high-risk activities. The practices cover a wide range of operations, including digging, pile driving, pipe installation, and construction of underground structures.

This is apply to all workers, contractors, and subcontractors involved in excavation-related tasks. They emphasize:

- General safety requirements

- Soil classification

- Confined space management

- Permit systems

- Protection of employees

- Safe access and egress

- Equipment operation

- Handling of excavated materials

- Dust control

- Training and record keeping

Contents

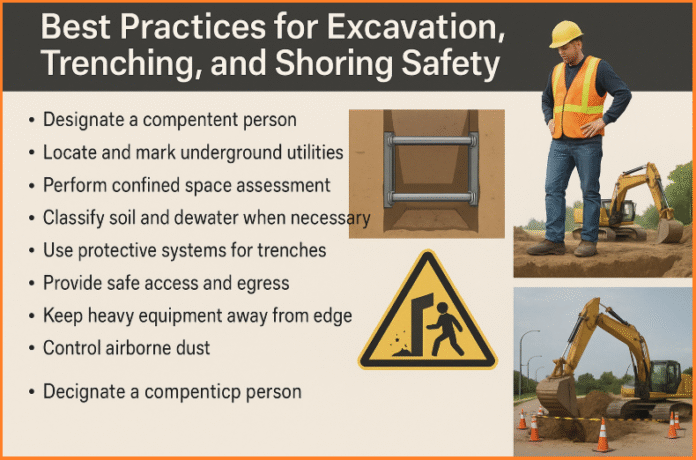

Key Safety Requirements

1. Pre-Work Assessment

- Contact utility companies to identify buried lines (sewer, water, gas, electric, etc.).

- Assess potential overhead hazards.

- Scan for underground obstructions and ensure markings are visible.

2. Inspections

- A Competent Person must inspect trenches and surrounding areas before each shift, after rainfall, or when conditions change.

- Daily logs must be maintained until project completion.

3. Soil Classification

Soil is categorized into Stable Rock, Type A, Type B, or Type C based on stability. Each type determines the required protective measures such as sloping, benching, or shoring.

4. Permit System

- Excavation deeper than 0.3 meters requires a permit.

- Authorized permit issuers must be trained and appointed in writing.

- Permits should not be older than 60 days at the time of work.

5. Protection of Employees

Workers must be protected from cave-ins and falling materials through:

- Sloping or benching the sides of excavations.

- Installing shoring or trench shields.

- Using barriers, covers, and fall protection systems when depth exceeds 1.8 meters.

6. Safe Access

- Ladders, ramps, or steps must be provided in trenches deeper than 1.2 meters.

- Safe crossing structures with guardrails should be installed.

7. Equipment Safety

- Heavy machinery must be kept at least 1.5 times the depth of excavation away from the edge.

- Workers must never stand under suspended loads.

- Reflective vests are mandatory where vehicle movement is involved.

8. Handling Excavated Materials

- Spoil piles and equipment must be placed at least 2 feet from the edge.

- Retaining devices should prevent materials from sliding back into the excavation.

9. Dust Control

Water or other dust suppression methods should be used to minimize airborne hazards.

10. Training and Records

- Competent Persons must undergo initial training and refresher courses.

- Records of permits, designs, and inspections must be retained at the site.

Soil Classification Types (Simplified)

- Stable Rock: Can stand vertically without collapsing.

- Type A: Strong cohesive soils like clay, caliche, and hardpan.

- Type B: Medium-strength soils including silt, sandy loam, and previously disturbed soils.

- Type C: Weak soils such as sand, gravel, and submerged soils — the least stable.

Excavation, trenching, and shoring are critical but high-risk construction activities. Implementing protective systems, ensuring proper soil classification, enforcing permit controls, and conducting regular inspections significantly reduce the risk of accidents. With well-trained personnel and strict adherence to safety practices, projects can be executed efficiently while safeguarding the workforce.