INSPECTION, MAINTENENCE AND TRAINING FOR FIRE PROTECTION

IS:2190 suggest that routine maintenance, inspection and testing of all fire extinguishers in respect of their mechanical parts, extinguishing media and expelling means should be carried out by properly trained personnel at frequent intervals but at-least once in a month to make sure that these are in their proper condition and have not been accidentally discharged or lost pressure or suffered damage. Detailed procedure is also mentioned therein.

It is very difficult for a new worker to use any fire extinguisher, to connect a hydrant to start fire pump, to hold pressurised nozzle, to use fire ladder etc. Training is necessary for handling and operating any fire equipment. Therefore arrangement should be made for regular training and fire drill for all fire fighting staff. Fire Officer should conduct field demonstrations on fire fighting. The training should be for preventive as well as protective techniques. The frequency and nature of training will depend on the size and type of industry. In a refinery of chemical industry it should be more frequent and continuous. Training record should also be maintained.

All fire equipment should be in ready working condition. The defective equipment may prove dangerous in the event of fire. Therefore regular cleaning, lubricating and testing of all fire fighting equipment are most desirable. The defect can be noticed by inspection and testing only. Therefore it should be found beforehand and rectified immediately. Fire pumps – diesel and electrical – should be run everyday for certain time and their performance should be checked and recorded in a log-book. The extinguishers should be recharged as required. Hydrants, monitors, hose reels, nozzles, couplings, foam making equipment etc. should be regularly inspected, tested under pressure and kept in good and working condition.

A small inspection checklist is given here which can be expanded as per own requirement.

A Small Checklist for Fire Prevention

Heat and flame: No smoking areas clearly indicated. Ashes kept in metal containers. Gas connections closed when not in use. No gas leaks. Hot pipe clear of combustible materials.

Housekeeping: Premises free of combustible materials. Metal containers for oily rags. Safe storage of flammable. No leaks and drippings of flammable. No accumulations of rubbish. Passageways clear of obstacles. Necessary fire awareness signs and posters.

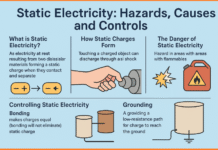

Electrical Equipment: No bare wiring or badly worn insulation. Ground connections clean and tight. Fuse and control boxes clean and closed. Motors and tools free of dirt and grease. Explosion proof fittings for flammable areas. No poor joints. No makeshift wiring.

Fire Protection Equipment: In proper place, unobstructed. Clearly marked, in working order.

For fire safety in chemical, textile and engineering industries, read respective chapters.

Fire load calculation

For the purpose of solving examples, following information needs to be understand.

An important factor in establishing the basis for the assessment of the fire risk pertaining to any building is the concept of ‘fire load’ which indicates the quantity of heat liberated per unit area when a building and its contents are completely burnt.

All occupancies/buildings, etc. can be graded according to their fire hazard and are to be provided for with suitable fire precautions on the basis of the fire load.

Hence, grading of building according to both, fire load and fire resistance, can be made.

The formula for calculating fire load is as under:

Fire load = (combustibles in kg) × calorific value in kcl/kg

Floor area in square meters

Fire grading of the structures:

Structural elements of buildings are graded according to the time factor which is nearly equal to but does not exceed the test period which the element fulfils its specified requirements.

Accordingly, all structural elements have been graded under the following five categories depending upon their fire resistance.

Grade 1….. 6 hours

Grade 2….. 4 hours

Grade 3….. 2 hours

Grade4…… 1 hours

Grade 5….. 0.5 hours

Occupancies of High fire load:

Godowns, warehouses, etc. This category as per I.S. specifications exceeds the fire load by 55,000 kcl/sq.mtr, but does not exceed an average of 1,100,000 kcl/sq.mtr of floor area. A fire resistance of 4 hours for these types of occupancies is considered sufficient.

(For reference, the maximum for this type in F.P.S system is 4,00,000 B.Th.U/sq.ft exceeding an average of 2,00,000 B.Th.U/sq.ft).

Occupancies of Moderate fire load:

Retail shops, bazaars, stalls, factories etc. Here the fire load exceeds 2,75,000 kcal/sq.mtr, and is up to 550,000 kcal/sq.mtr. Occupancies of this type should have a fire resistance of two hours.

Occupancies of Low fire load:

Ordinary buildings for residential purposes, hotels, offices, schools, etc, or occupancies having a fire load not exceeding 2,75,000 kcal/sq.mtr of net floor area of any compartment, nor exceeding an average of 550,000 kcal/sq.mtr on a limited isolated area. (for reference, the maximum for this type in F.P.S system is 1,00,000 B.Th.U/sq.ft)

The fire resistance required by buildings of this category to withstand the complete burn-out of their contents without collapse is 1 hour as has been found after tests. Extensive investigations carried out in Switzerland and Germany have shown that the fire load in offices varies from 10kg to 30kg/sq.mtr wood equivalent to 43,356 to 130,068 kcl/sq.mtr. This type of occupancy has an one hour rating with maximum fire loading up to 60 kg/sq.m. equivalent to 270,978 kcl/sq.mtr.

Sir please send me

Ok sir

Respect for you sir

Thank You sir

You are a man of letters in HSE.

MAY GOD NEVER GIVE YOU SORROW.