SAFETY MANAGEMENT ITS RESPONSIBILITIES

Safety Management Defined

We can define the safety management as ‘The accomplishment of safety objectives by first establishing the safety objectives and then by attaining them through the process of planning, organizing, staffing, directing and controlling i.e. motivating and coordinating all efforts to attain those objectives and also innovating to improve them for the future.

Safety Organization (higher level management) can also be defined as a definite, planned and organized set up whose purpose is to enlist and maintain the combined efforts of organized personnel for the purpose of total loss control including accidents and environmental protection in an industry or establishment.

In a small unit where there is no safety officer or department or group of persons for safety activity, even a single person -supervisor, occupier or worker should assume the duty of safety management.

CLICK HERE FOR ? [Main] Principle of industrial safety management

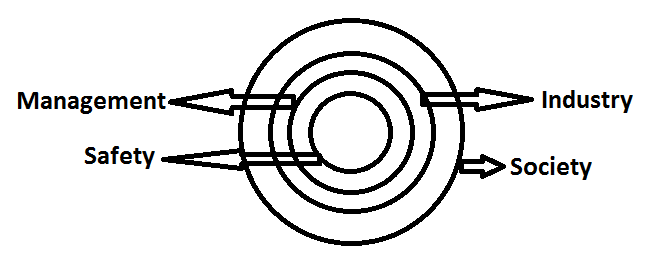

Industries are inevitable – in modern society because human needs of foods, clothes, homes, amenities, luxuries, services and knowledge are to be fulfilled.

It is also required for employment. Wants of modern society are day by day increasing with the increase in population, invention, technology, industrialization and human desires.

How to produce, distribute and supply all such wants to the whole humanity? Mass production is possible by industries only. Distribution and supply are possible by trade and business. Therefore place of industry is ahead, vital and most desirable.

CLICK HERE FOR ? Key Elements of a Health and Safety Management System

We cannot eliminate industry from society. Only its hazards are to be eliminated and for this purpose, the safety management is desired. As place of industry in society is inevitable, similarly the place of safety in industry is also inevitable, because safety is most required in industries.

Industrialization has been defined by Dr. Luigi Parmeggiani as “the process of change in the mode of production to utilize more capital per unit of output, higher levels of technology and management widening with cost economics of scale and specialized location of plant, type of plant and skills”.

Industrialized country has been defined as one that derives more than 30% of its gross domestic product (GDP) from manufacturing, while a semi industrialized country derives 20 to 30%, an industrializing country between 10 to 19% and a nonindustrial country less than 10% from the same source.

CLICK HERE FOR ? Span of Safety Management

Accident problem created by the. Increasing number of accidents and their costs with rapid industrialization call for accident prevention work.

This is an essential task for every management. Occupational hazards, accidents and diseases, are to be prevented by providing protection to men and machines, by good maintenance, medical health checkups, good working and living

Conditions, prompt and effective legislation and last but not the least by constant education, training and motivation of workers to work safely.

Thus, a place of safety in industry must be accepted and strengthened by providing efficient safety management.

CLICK HERE FOR ? Computer Application use in safety management

Safety Management’s Role:

This is a many-fold role as described in eleven heads as under –

General and Scientific Functions

The basic safety role of any industrial management is well derived from the five steps of accident prevention suggested by H.W. Heinrich.

These are organization, facts finding, analysis of the facts found, selection of remedy and application of the remedy.

CLICK HERE FOR ? Process safety and risk management

The six functions of scientific safety management are:

- Planning: It includes setting salty objectives, formulating safety policy, safety programming, budgeting and determining safe or standard procedures. Good planning at the design stage always helps. Planning for site, effluent disposal, facilities for storing and handling raw materials, intermediates and products, types of floor, roof, construction, lighting, ventilation, layout of machinery, pressure vessels, lifting machines, ‘hazardous processes, boilers, storage tanks, repair services, auxiliaries, utilities, fire protection, training, welfare and sanitary facilities etc., must consider safety points at this initial stage so that the planning and design defects can be eliminated or minimized from the beginning. Previous plans approval and correction after operation are also necessary.

- Organizing: It includes establishment of the formal structure of authority through which work subdivisions are defined, arranged, and co-coordinated for the planned safety objectives.

An organizational set-up describes four classes of management – Top or Executive, Intermediate, Middle and Supervisory management. The set-up may vary according to the size and nature of establishment, A model safety organization is shown in below picture.

The Company Board decides the safety policy and objectives and monitors its implementation. Managing Director is re-portable to the Board for implementation of safety policy.

CLICK HERE FOR ? MANAGEMENT INFORMATION SYSTEM (MIS) FOR SAFETY

Safety executive or safety department reports to MD. Managers are answerable to the Safety Department or Executive for application of the safety arrangements.

Supervisors are re-portable to the Managers for shop floor extension and application of safety policy, rules and procedures. Workers are ‘responsible to their supervisors for effectively carrying out the safety rules and precautions.

Safety Representatives selected from workers and supervisors advise and assist to Safety Committee for promoting health and safety. Safety Committee advises on all matters of safety and health to the Managers and the Managing Director.

CLICK HERE FOR ? HISTORY OF THE SAFETY MOVEMENT AND THE FACTORIES ACT

- Staffing: It includes personnel function of recruitment and training the staff and maintaining safe and favorable conditions of work through personnel.

- Directing: It is a continuous desk of taking decisions, ordering, instructing, guiding and advising on all matters of safety.

- Controlling: It includes performing, evaluating and correcting the performance according to objectives, procedures and plans. it is concerned with quality, times, uses and cost m safety matters.

- Co-coordinating: It includes interrelating and synchronizing the different activities for achieving safety goals.

PLEASE SHARE THIS ARTICLE WITH YOUR RELEVANT FRIENDS

very useful.

Very useful, thanks.