Contents

Industrial Safety Belts and Harnesses: IS 3521:1999 and International Practices

Working at heights remains one of the most hazardous activities in industries such as construction, mining, shipbuilding, electrical services, and maintenance. Falls from elevation contribute to a large proportion of workplace accidents globally. To mitigate these risks, safety belts and harnesses are most important components of personal protective equipment (PPE).

In India, the governing standard is IS 3521:1999 – Industrial Safety Belts and Harnesses (Third Revision), issued by the Bureau of Indian Standards (BIS). This standard aligns closely with international benchmarks like ISO 10333 (Personal Fall Arrest Systems), EN 361 (Full Body Harnesses, Europe), and AS 1891 (Australia).

Scope of IS 3521:1999

The standard specifies the requirements for safety belts and harnesses along with accessories such as lifelines, safety clamps, and hooks. While anchorage points are not covered, the standard emphasizes that secure anchorage must always be identified before use.

Applications include:

- Plant maintenance and industrial duty at height

- Construction, erection, and installation jobs

- Electrical line maintenance and pole climbing

- Confined space work (silos, chimneys, sewers, shipholds)

- Building and structural maintenance (painting, window cleaning)

- Mineshafts, quarries, and open-cast mining

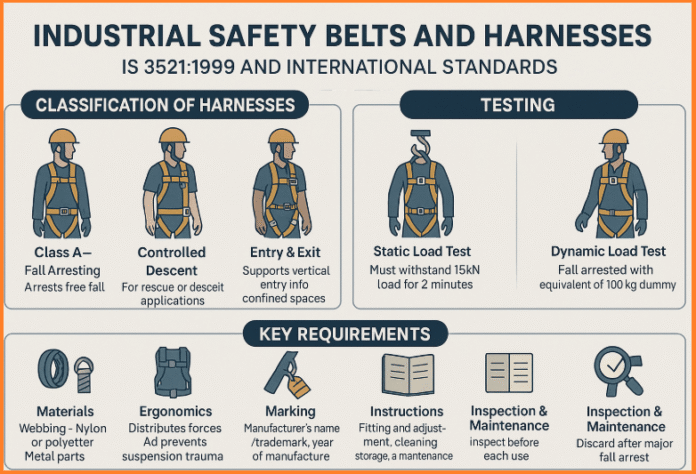

Classification of Harnesses

IS 3521:1999 classifies harnesses based on work position and intended use, broadly aligning with ISO 10333 and EN 361.

- Class A – Fall Arresting: Arrests a free fall, prevents hitting ground/structure.

- Class D – Controlled Descent: For rescue or descent applications.

- Class E – Entry & Exit: Supports vertical entry into confined spaces.

- Class L – Ladder Climbing: With frontal attachment for vertical systems.

- Class P – Work Positioning: Holds workers in position while leaving hands free.

Design and Construction

Materials

- Webbing: Nylon or polyester, minimum 40 mm width and 3 mm thickness.

- Tensile strength: Minimum 19.6 kN (≈2000 kg) load-bearing capacity.

- Threads: High-strength synthetic fibres (nylon, polyester) in contrasting colour for easy inspection.

- Rivets and washers: Copper, to prevent corrosion.

- Metal parts (hooks, buckles, clamps): Forged steel, corrosion-protected with chromium plating (≥8 µm) or powder coating (≥45 µm).

Ergonomics

Harnesses are designed to distribute impact forces over the pelvic area, thighs, shoulders, and chest, reducing risk of injury and suspension trauma. Comfort, adjustability, and prevention of strap slippage are mandatory design features.

Testing and Performance Requirements

IS 3521:1999 introduced two critical tests, aligning with global standards like ISO 10333 and ANSI Z359 (USA):

- Static Load Test – Harness must withstand 15 kN load for 2 minutes without failure.

- Dynamic Load Test – Simulated fall using a 100 kg dummy dropped from prescribed free-fall distances. Harness must arrest the fall without releasing or damaging the dummy.

Other tests include:

- Flammability resistance of webbing and ropes.

- Corrosion resistance of metal parts.

- Performance testing under repeated falls to ensure durability.

Marking, Instructions, and Maintenance

Each harness must be clearly marked with:

- Manufacturer’s name/trademark and batch/serial number.

- Year of manufacture and fibre type.

- Purpose and limitations of attachment points.

- Warnings against misuse, alterations, or unauthorized repairs.

Instructions must include:

- Fitting and adjustment guide.

- Inspection before every use.

- Cleaning, storage, and maintenance steps.

- Mandatory annual inspection by a competent person.

- Guidance to discard harnesses after any major fall arrest.

Comparison with International Standards

- ISO 10333: Provides global specifications for full-body harnesses, energy absorbers, and lanyards. IS 3521 incorporates ISO 10333 principles, particularly in dynamic testing and ergonomic design.

- EN 361 (Europe): Similar requirements on full-body harnesses, attachment points, and dynamic testing. IS 3521 closely mirrors EN 361 for fall arrest harnesses.

- AS 1891 (Australia): Focuses heavily on rope access and fall arrest systems; IS 3521 has adopted provisions for controlled descent and confined entry similar to AS 1891.

Conclusion

The IS 3521:1999 standard provides a robust framework for the design, testing, and use of industrial safety belts and harnesses in India. By integrating international benchmarks like ISO 10333 and EN 361, it ensures worker safety, reliability of equipment, and global compatibility.

For maximum safety:

- Employers must enforce compliance with IS 3521 and train workers in correct harness use.

- Harnesses must undergo regular inspections and timely replacement.

- Secure anchorage points and compatible components should always be ensured.

In high-risk industries, adherence to IS 3521:1999 is not just a legal requirement but a critical life-saving measure.